Method and equipment for performing harmless treatment on organic waste gas through high-voltage current

A technology of organic waste gas and high-voltage current, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high cost, consumption of large amounts of clean water, consumption of filter consumables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

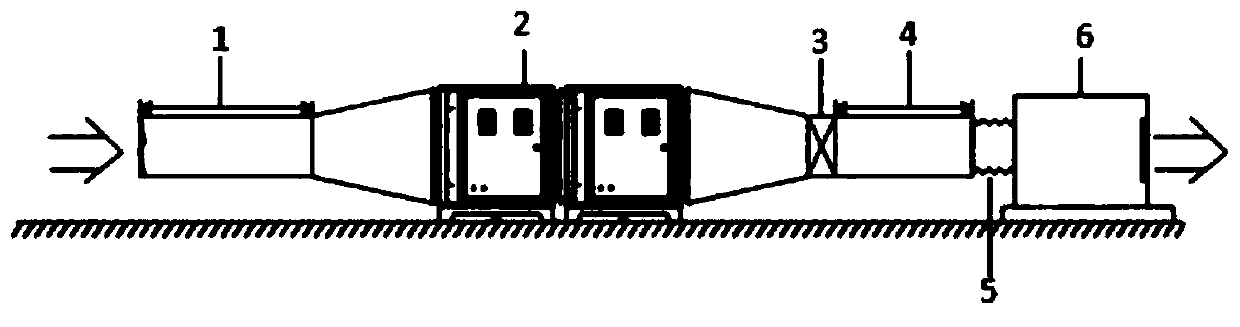

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] A method for harmless treatment of organic waste gas through high-voltage electric current, comprising the following steps:

[0025] 1) Introduce organic waste gas into the pipeline;

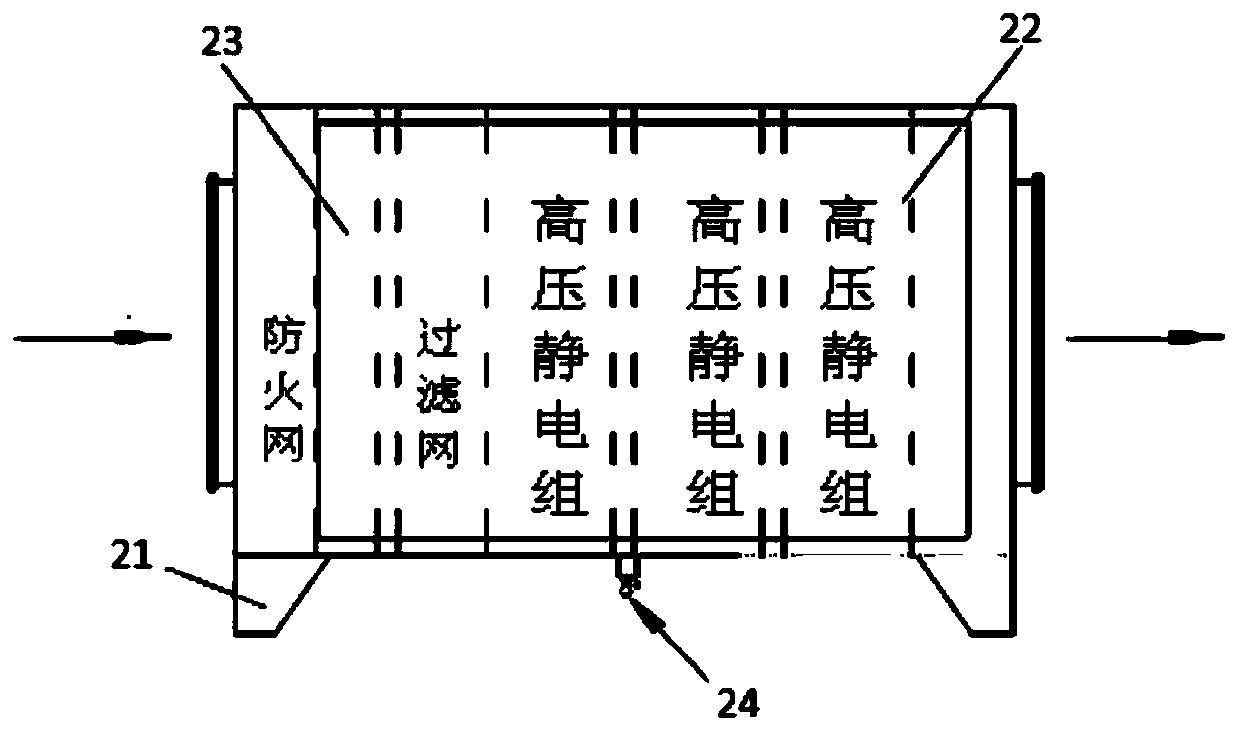

[0026] 2) Adsorb oil fume particles on the dust collection plate through high-voltage static electricity;

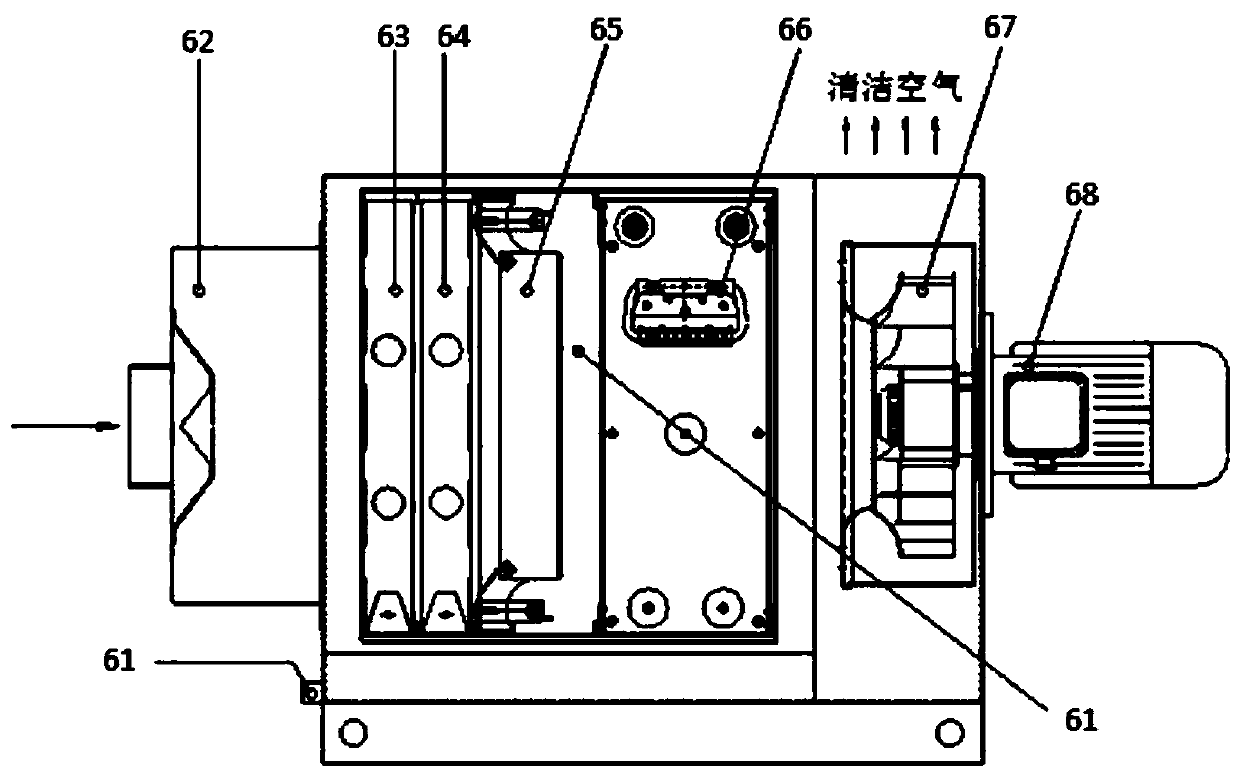

[0027] 3) The organic waste gas treated in step 2) is excited and decomposed by photon quantum tubes;

[0028] 4) discharge.

[0029] Wherein in step 2), the grease accumulated or dripped on the dust collecting plate is recovered.

[0030] Wherein step 3) in, described photon quantum tube can produce the light of 185 nanometers and 253.7 nanometers under the excitation of high-voltage power supply, and the light of 185 nanometers can be absorbed by most organic matter, because its photon ability is huge, can make molecule chemical bond break instantl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com