A method for preparing anatase titanium dioxide thin film on the surface of cotton fabric at low temperature

A technology of anatase titanium dioxide and titanium dioxide, which is applied in the fields of plant fiber, textiles, papermaking, fiber treatment, etc., can solve the problems of high cost of high-frequency electric field heating and is not suitable for large-scale production in factories, and achieve low preparation temperature and low raw material cost Low cost and high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix 3mL of absolute ethanol, 6mL of glacial acetic acid and 10mL of tetra-n-butyl titanate, then slowly add it dropwise to 120mL of a mixed solution of acetic acid and water with a pH of 2.5 for hydrolysis, and form a light yellow color after vigorous stirring transparent sol.

[0029] Soak the pretreated cotton fabric in titanium dioxide sol for 3 minutes, dip twice and roll it twice (the liquid rolling rate is 80%), pre-dry it at 80°C for 3 minutes, steam it in a steam box at 100°C for 3 hours, and finish drying the cotton fabric. The process of preparing titanium dioxide film on the surface of fabric.

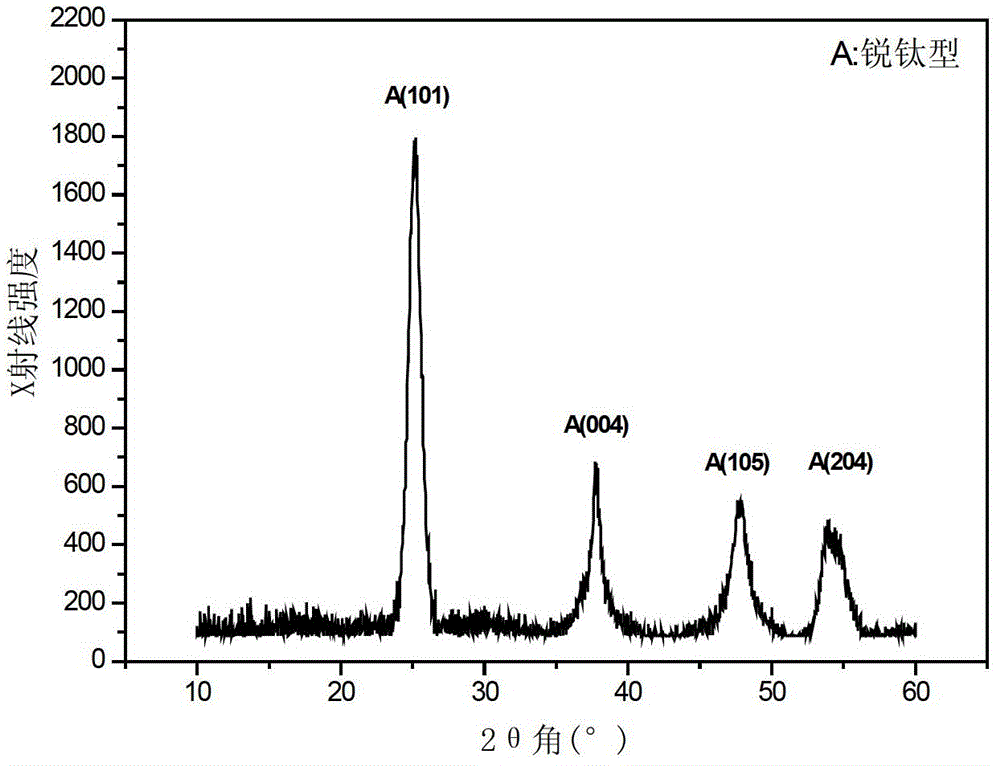

[0030] According to the national standard GB / T8629-2001 "Household Washing and Drying Procedures for Textile Testing", the titanium dioxide modified cotton fabrics were washed and dried (type A washing machine, 5A washing procedure, A-type drying procedure), after 50 times of washing Finally, characterize the XRD pattern of the film, see figure 1 . The test results...

Embodiment 2

[0032] Mix 3mL of absolute ethanol, 6mL of glacial acetic acid and 10mL of tetra-n-butyl titanate, then slowly add it dropwise to 120mL of a mixed solution of acetic acid and water with a pH of 2.5 for hydrolysis, and form a light yellow color after vigorous stirring transparent sol.

[0033] Soak the pretreated cotton fabric in titanium dioxide sol for 3 minutes, dip twice and roll it twice (the liquid rolling rate is 80%), pre-dry it at 80°C for 3 minutes, steam it in a steam box at 100°C for 3 hours, and finish drying the cotton fabric. The process of preparing titanium dioxide film on the surface of fabric.

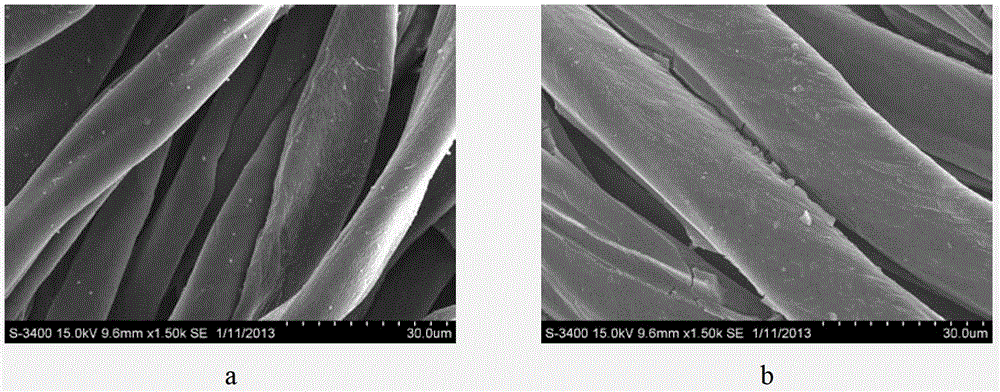

[0034] According to the national standard GB / T8629-2001 "Household Washing and Drying Procedures for Textile Testing", the titanium dioxide modified cotton fabrics were washed and dried (type A washing machine, 5A washing procedure, A-type drying procedure), after 50 times of washing Finally, the film-forming state of the fabric surface was characterized by scanning ...

Embodiment 3

[0036] Mix 3mL of absolute ethanol, 6mL of glacial acetic acid and 10mL of tetra-n-butyl titanate, then slowly add it dropwise to 120mL of a mixed solution of acetic acid and water with a pH of 2.5 for hydrolysis, and form a light yellow color after vigorous stirring transparent sol.

[0037] Soak the pretreated cotton fabric in titanium dioxide sol for 3 minutes, dip twice and roll it twice (the liquid rolling rate is 80%), pre-dry it at 80°C for 3 minutes, steam it in a steam box at 100°C for 3 hours, and finish drying the cotton fabric. The process of preparing titanium dioxide film on the surface of fabric.

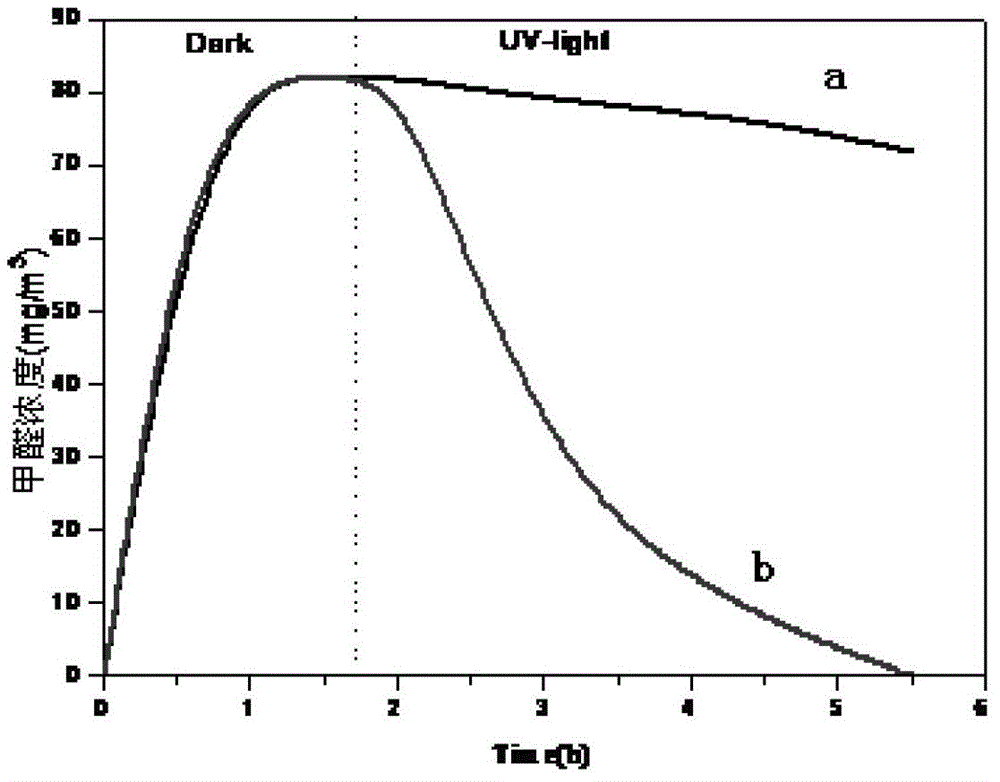

[0038] According to the national standard GB / T8629-2001 "Household Washing and Drying Procedures for Textile Tests", the titanium dioxide modified cotton fabrics were washed and dried (type A washing machine, 5A washing procedure, A-type drying procedure), after 50 times of washing Finally, the fabric prepared with titanium dioxide film was placed in a closed contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com