A kind of emulsified asphalt for degrading waste gas

A technology of emulsified asphalt and exhaust gas, which is applied in the processing of tar pitch/petroleum pitch/natural asphalt, chemical instruments and methods, chemical/physical processes, etc. It can solve problems such as low catalytic efficiency, neglect of exhaust gas, and insufficient utilization of titanium dioxide. Achieve the effect of saving cost and fully purifying exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

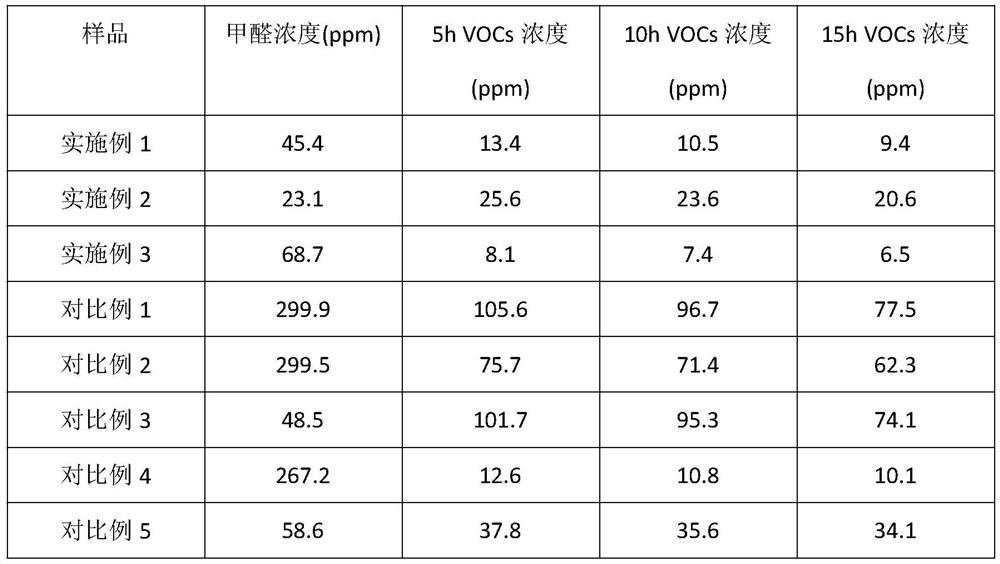

Examples

Embodiment 1

[0025] Disperse 5g of the modified catalyst and 5g of the slow-release capsules in 10g of water to obtain an additive mixture;

[0026] Add the additive mixture to 80g of basic emulsified asphalt (solid content 60%), and mix evenly to obtain emulsified asphalt for degrading waste gas;

[0027] Among them, 85g molecular sieve (MCM-41) is impregnated in the dispersion containing 10g (calculated as titanium dioxide) titanium tetrachloride, 1g (calculated as ferric oxide) ferric chloride and stirred for 30min, adding sodium hydroxide to make the dispersion When the pH value reaches 12, continue stirring for 1 hour, filter, dry at 100° C. for 3 hours, and air calcinate at 550° C. for 3 hours to obtain the first catalyst. The first catalyst is immersed in a dispersion containing 4 g (calculated as manganese dioxide) of manganese acetate. After impregnation, filter, dry at 100°C for 3 hours, and air calcinate at 550°C for 3 hours to obtain the modified catalyst.

[0028] Among them,...

Embodiment 2

[0030] Disperse 10g of the modified catalyst and 1g of the sustained-release capsule in 15g of water to obtain an additive mixture;

[0031] Add the additive mixture to 74g of basic emulsified asphalt (solid content 60%), and mix evenly to obtain emulsified asphalt for degrading waste gas;

[0032] Among them, 73g molecular sieve (MCM-41) was impregnated in the dispersion containing 20g (calculated as titanium dioxide) titanium tetrachloride, 4g (calculated as ferric oxide) ferric chloride and stirred for 30min, adding sodium hydroxide to make the dispersion When the pH value reaches 12, continue stirring for 1 hour, filter, dry at 100° C. for 3 hours, and air calcinate at 550° C. for 3 hours to obtain the first catalyst. The first catalyst is immersed in a dispersion containing 3 g (calculated as manganese dioxide) of manganese acetate. After impregnation, filter, dry at 100°C for 3 hours, and air calcinate at 550°C for 3 hours to obtain the modified catalyst.

[0033] Among...

Embodiment 3

[0035] Disperse 1g of the modified catalyst and 10g of sustained-release capsules in 20g of water to obtain an additive mixture;

[0036] Add the additive mixture to 69g of basic emulsified asphalt (70% solid content), and mix evenly to obtain emulsified asphalt for degrading waste gas;

[0037] Among them, 84.5g molecular sieve (MCM-41) was impregnated in the dispersion containing 5g (calculated as titanium dioxide) titanium tetrachloride, 0.5g (calculated as ferric oxide) ferric chloride and stirred for 30min, adding sodium hydroxide to make When the pH value of the dispersion reaches 12, continue stirring for 1 hour, filter, dry at 100°C for 3 hours, and air calcinate at 550°C for 3 hours to obtain the first catalyst. , impregnated, filtered, dried at 100°C for 3h, and air calcined at 550°C for 3h to obtain the modified catalyst.

[0038]Among them, 15g of sodium alginate was dissolved in 1L of 10% hydrogen peroxide solution to obtain a mixed solution, and the mixed soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com