Coating machine for ultrathin membrane coating

A technology of ultra-thin films and coating machines, applied in spraying devices, spray booths, etc., can solve the problems of being unsuitable for mass production, affecting the uniformity of coating thickness, and difficult to realize automatic continuous production, etc., achieving high spraying efficiency and high spraying efficiency. Uniform thickness and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

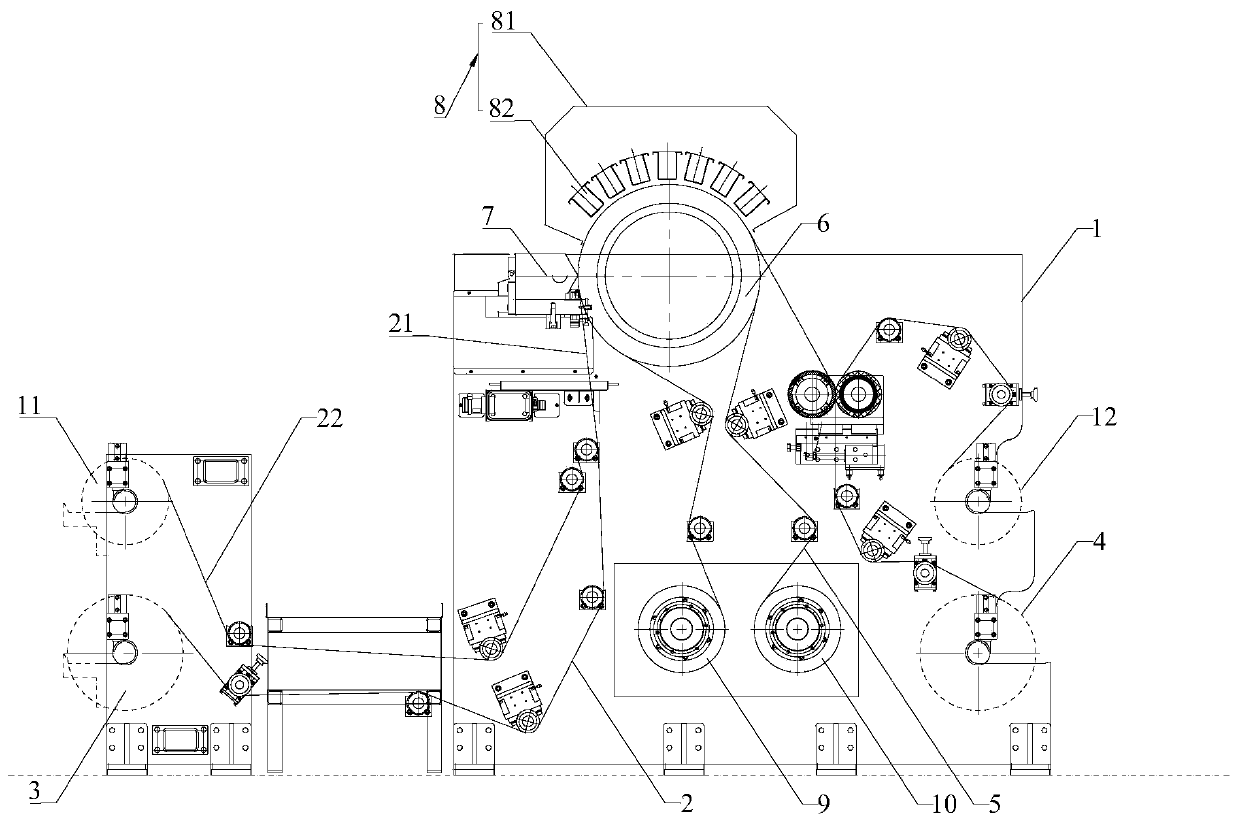

[0045] Please refer to figure 1 , Embodiment one of the present invention is: a kind of coating machine that is used for ultra-thin film coating, comprises frame 1, is used for releasing the first unwinding roller 3 of coated substrate 2 and is used for reclaiming coated substrate 2, the first winding roller 4, the first unwinding roller 3 and the first winding roller 4 are fixed on the frame 1, and also include a lining film 5 and a vacuum suction roller arranged on the frame 1 6. Spraying mechanism 7 and drying mechanism 8, the vacuum adsorption roller 6 is arranged between the first unwinding roller 3 and the first winding roller 4, and the vacuum adsorption roller 6 is covered with the lining film 5. The side of the liner film 5 away from the vacuum suction roller 6 is attached to the reverse side of the coating substrate 2, and the spraying mechanism 7 is arranged on the coating substrate 2 near the feed end of the vacuum suction roller 6 On the front side, the drying me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com