A kind of heat-sealing composite material and preparation method thereof

A composite material and hot-melt adhesive technology, applied in the field of paper-plastic materials, can solve the problems of increasing the output of defective products, residual ethylene oxide, waste of raw materials, etc., to ensure sterility and integrity, prevent ethylene oxide Residue of alkane and the effect of reducing the output of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

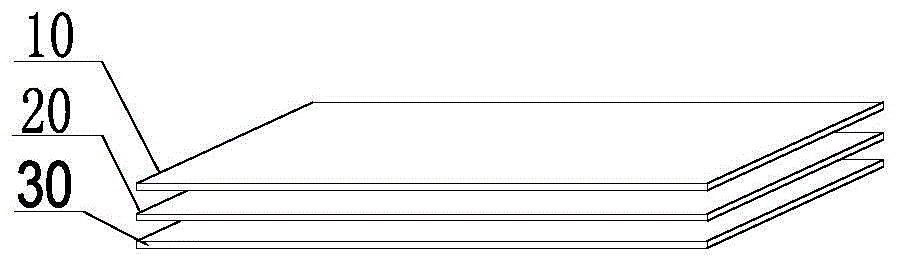

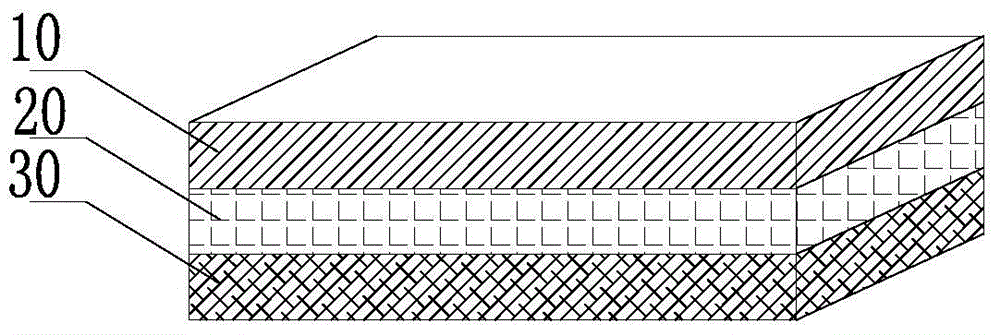

[0021] Such as Figure 1-4 As shown, in an embodiment of a heat-sealing composite material of the present invention, a heat-sealing composite material 100, the composite material includes an insulating outer layer 10, an intermediate layer 20 and a heat-sealing inner layer 30, the described The insulating outer layer 10 is polyethylene terephthalate PET. PET has excellent physical properties, chemical properties, dimensional stability, transparency and recyclability, and is used in industrial films. The thickness of the PET film is 0.01-0.015mm; The contact surface of the isolation outer layer 10 and the middle layer 20 is coated with hot melt adhesive for bonding, and the middle layer 20 is medical dialysis paper, and the thickness of the medical dialysis paper is 0.11-0.11mm. 0.12mm; Medical dialysis paper is used in the field of medical packaging, and its characteristic is to allow some things to penetrate and prevent other parts from penetrating. The penetration allowed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com