Ultrasonic auxiliary impregnation composite material 3D printing device

A composite material and 3D printing technology, applied in the field of 3D printing, can solve the problems of unstable molding quality, low strength and rigidity of parts, and high defects, and achieve the effect of improving mechanical properties and production efficiency, improving efficiency and reducing internal defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

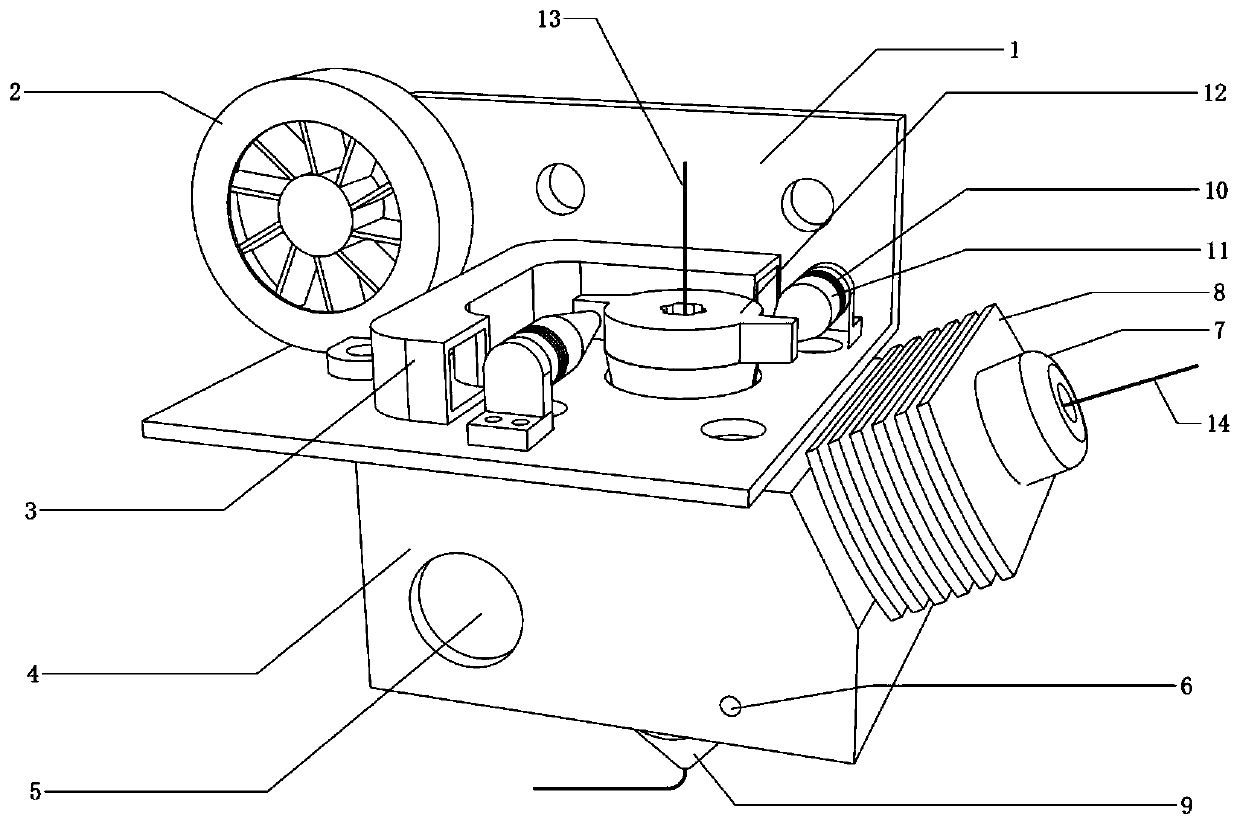

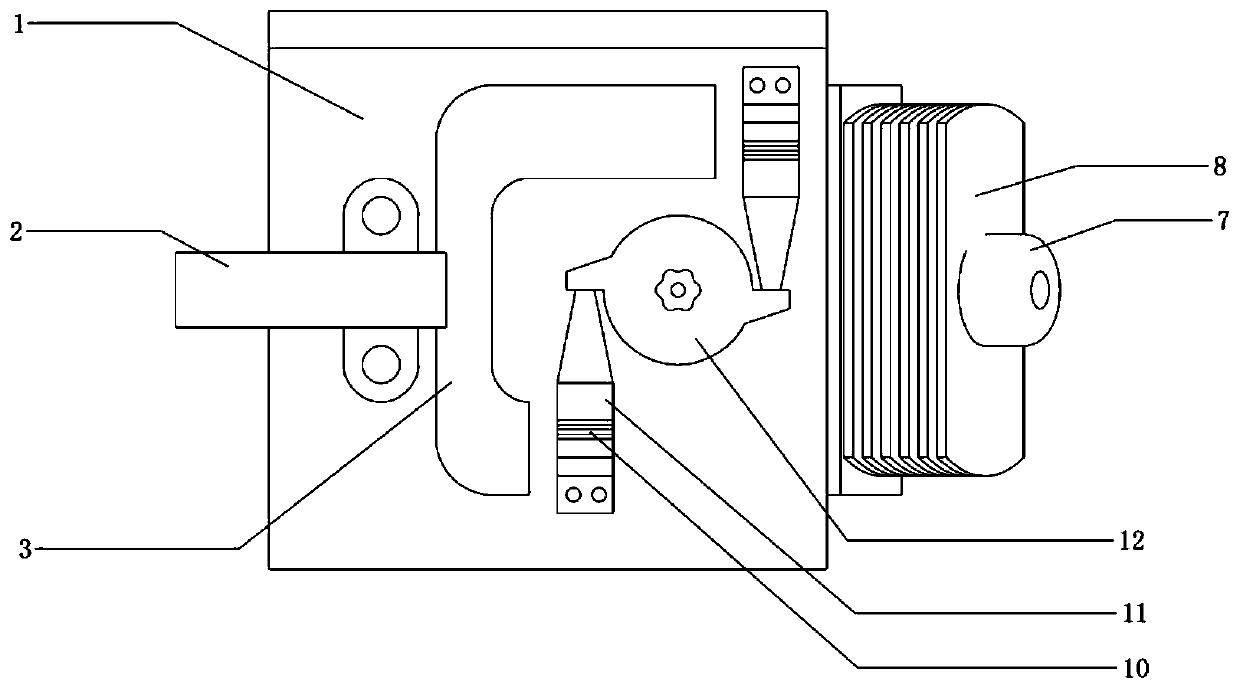

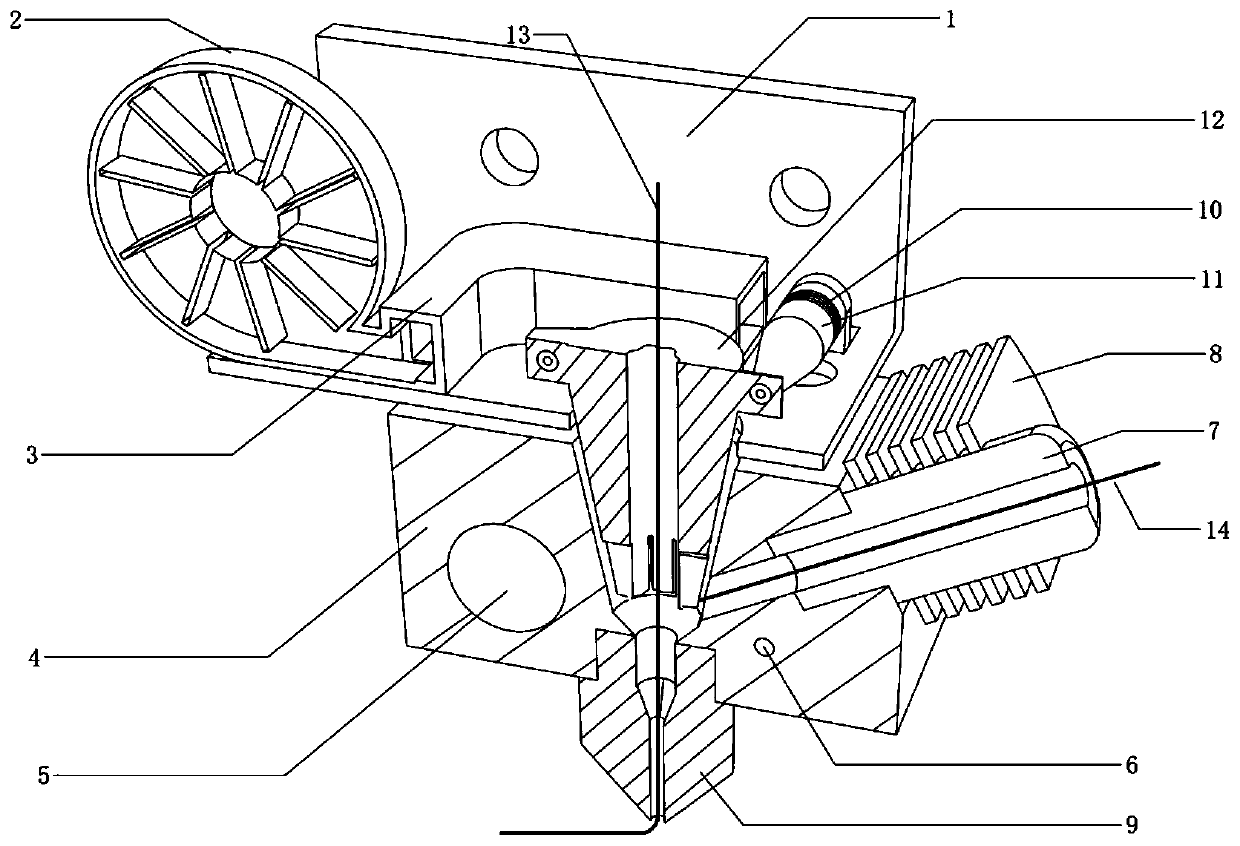

[0026] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] A composite material 3D printing device for ultrasonic assisted impregnation, comprising: a printing support, a composite module, an ultrasonic vibration module and a heat dissipation module, the printing support is arranged on the composite module, the ultrasonic vibration module and the heat dissipation module The modules are all set on the printing support, the heat dissipation module is used for heat dissipation of the ultrasonic vibration module, and the composite module is used to realize the integration of composite material preparation and forming, so that the reinforced fiber is directly printed after being composited with the molten thermoplastic matrix As a component, the ultrasonic vibration module is used to fully impregnate the reinforcing fibers with a molten thermoplastic matrix.

[0028] Please refer to figure 1 , for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com