Hydroxyl terminated liquid rubber-polyurethane modified epoxy resin polymer and preparation method thereof

A technology of polyurethane modification and epoxy resin, which is applied in the field of chemical synthesis materials, can solve the problems that the comprehensive performance cannot meet the use environment, the resin performance is single, and the temperature resistance is low, so as to achieve large phase interface, high tensile strength, high resistance The effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

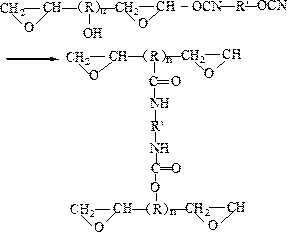

Method used

Image

Examples

Example Embodiment

[0025] Example 1

[0026] A hydroxyl-terminated liquid rubber-polyurethane modified epoxy resin polymer, the modified epoxy resin polymer is prepared from the following mass parts of materials through Michael addition reaction: 30 parts of prepolymer with NCO end groups , 70 parts of bisphenol A epoxy resin, the epoxy value of the modified epoxy resin is 0.38mol / 100g, and the relative molecule is 5000.

[0027] A method for preparing hydroxyl-terminated liquid rubber-polyurethane modified epoxy resin polymer. The modified epoxy resin is the above-mentioned modified epoxy resin polymer and includes the following steps:

[0028] Step 1. Prepare a prepolymer with NCO end groups: weigh 35 parts of liquid rubber, 235 parts of dihydroxy polyether and 5 parts of catalyst into a three-necked flask with stirring, heating and condensing devices based on mass fraction. Stir, when the solution is heated to 50-55°C, start to add 200 parts of polyisocyanate dropwise, dripping time 30min, heating ...

Example Embodiment

[0032] Example 2

[0033] A hydroxyl-terminated liquid rubber-polyurethane modified epoxy resin polymer, the modified epoxy resin polymer is prepared from the following mass parts of materials through Michael addition reaction: 15 parts of prepolymer with NCO end groups 85 parts of bisphenol A epoxy resin, the epoxy value of the modified epoxy resin is 0.46 mol / 100 g, and the relative molecule is 5500.

[0034] A method for preparing hydroxyl-terminated liquid rubber-polyurethane modified epoxy resin polymer. The modified epoxy resin is the above-mentioned modified epoxy resin polymer and includes the following steps:

[0035] Step 1. Prepare the prepolymer with NCO end groups: weigh 60 parts of liquid rubber, 350 parts of dihydroxy polyether and 10 parts of catalyst into a three-necked flask with stirring, heating and condensing devices based on mass fraction. Stir, when the solution is heated to 50-55°C, start to add 320 parts of polyisocyanate dropwise, dripping time 30min, heat ...

Example Embodiment

[0039] Example 3

[0040] A hydroxyl-terminated liquid rubber-polyurethane modified epoxy resin polymer, the modified epoxy resin polymer is prepared by Michael addition reaction with the following parts by mass: 25 parts of prepolymer with NCO end groups 75 parts of bisphenol A epoxy resin, the epoxy value of the modified epoxy resin is 0.38 mol / 100 g, and the relative molecule is 5000.

[0041] A method for preparing hydroxyl-terminated liquid rubber-polyurethane modified epoxy resin polymer. The modified epoxy resin is the above-mentioned modified epoxy resin polymer and includes the following steps:

[0042] Step 1. Prepare a prepolymer with NCO end groups: weigh 52 parts of liquid rubber, 210 parts of dihydroxy polyether and 4 parts of catalyst into a three-necked flask with stirring, heating and condensing devices based on mass fraction. Stir, when the solution is heated to 50-55°C, start to add 182 parts of polyisocyanate dropwise, dripping time 30min, heat up to 75-80°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com