Exhaust gas trapping device and method

A waste gas and air intake pipeline technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of reducing gas-liquid contact, uneven distribution of gas-liquid, and affecting absorption effect, etc., to increase the phase interface, Improve mass transfer efficiency and improve absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

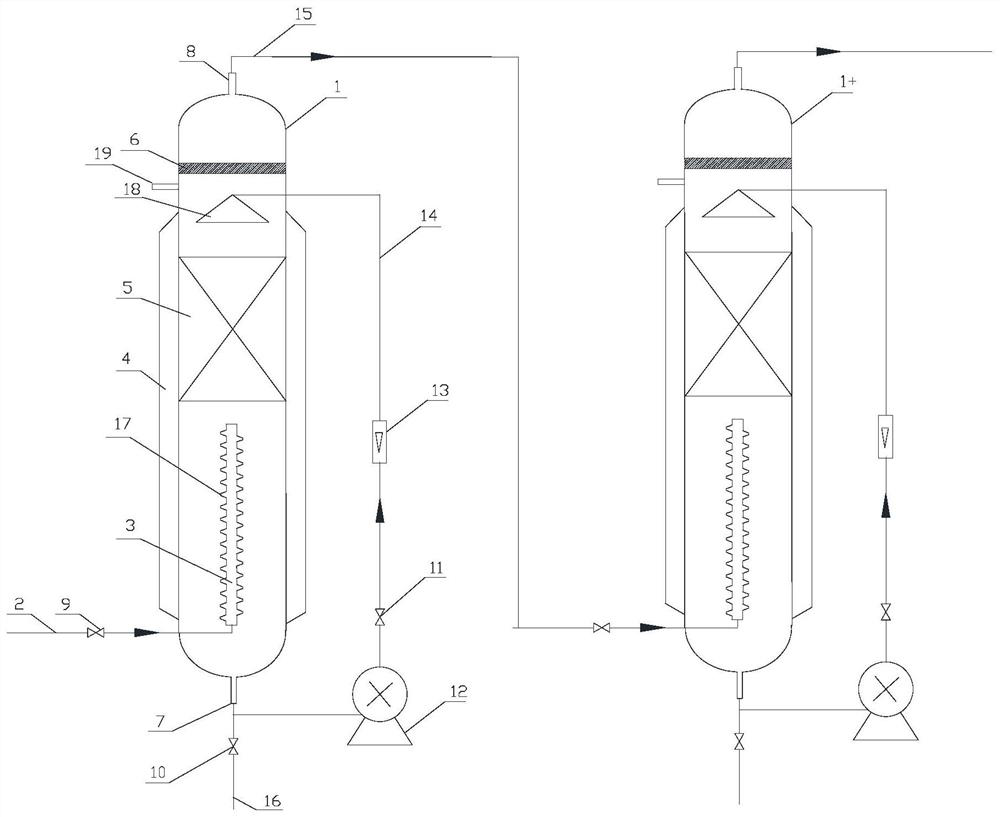

[0030] Example 1 Exhaust gas capture device

[0031] Exhaust gas capture devices such as figure 1 As shown, including the reaction chamber 1, the height-to-diameter ratio of the reaction chamber 1 is 5-15, the outer wall of the reaction chamber is provided with a heat exchange jacket 4, the middle and lower part of the reaction chamber is provided with an air inlet pipeline 2, and the air inlet pipeline 2 passes through the first valve 9 For control, a gas outlet 8 is provided at the top of the reaction chamber, and a liquid outlet 7 is provided at the bottom, and the liquid outlet 7 is controlled by a second valve 10 . The air intake pipeline 2 is connected to the multi-nozzle injection pipe 3 arranged in the reaction chamber, the multi-nozzle injection pipe 3 is vertically arranged along the longitudinal axis of the reaction chamber, the free end is closed, and the nozzles 17 with a diameter of 1 mm to 5 mm are uniformly distributed on the pipe wall A packing unit 5 is arra...

Embodiment 2

[0033] use figure 1 Exhaust gas capture device for CO in exhaust gas 2 The trapping process includes the following steps: diethanolamine is selected as the absorption liquid, the temperature of the heat exchange jacket is controlled at 15° C., the height-to-diameter ratio of the reaction chamber 1 is 10, and the diameter of the injection nozzle 17 is 2 mm. Before the operation of the device, close the second valve 10 of the liquid outlet, inject a certain amount of absorption liquid, open the third valve 11 and the pump 12 of the liquid circulation pipeline, and control the flow rate; open the first valve 9 of the gas inlet, and the CO 2 The exhaust gas is passed into the reaction chamber, and the liquid is fully contacted with the absorption liquid through the injection nozzle 17, and then enters the packing layer for secondary absorption, and the treated exhaust gas is discharged through the gas outlet. After the absorption liquid is saturated, the third valve 11 and the pu...

Embodiment 3

[0035] use figure 1 The device shown is for use with NH 3 The treatment of low-concentration industrial waste gas includes the following steps: dilute sulfuric acid is selected as the absorption liquid, and only the spray bubbling section can be used to meet the demand. The temperature of the heat exchange jacket is controlled at 5°C, the height-to-diameter ratio of reaction chamber 1 is 8, and the injection nozzle The diameter is 2mm. Before the operation of the device, close the second valve 10 of the liquid outlet, and inject a certain amount of absorption liquid without opening the third valve 11 and the pump 12 of the liquid circulation pipeline; open the first valve 9 of the gas inlet, and the NH 3 The exhaust gas is passed into the reaction chamber, and the liquid is fully contacted with the absorption liquid through the injection nozzle 17 and then discharged through the gas outlet. After the absorption liquid is saturated, open the liquid outlet valve 10 to collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com