High-speed jet purification method and device for blast furnace gas ammonium chloride

A high-speed jet, blast furnace gas technology, applied in the field of high-speed jet purification, blast furnace gas ammonium chloride high-speed jet purification, can solve the problems of loss, pipeline corrosion, gas burner blockage, etc., to reduce industrial water consumption, turbulence High degree, efficient reunion purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

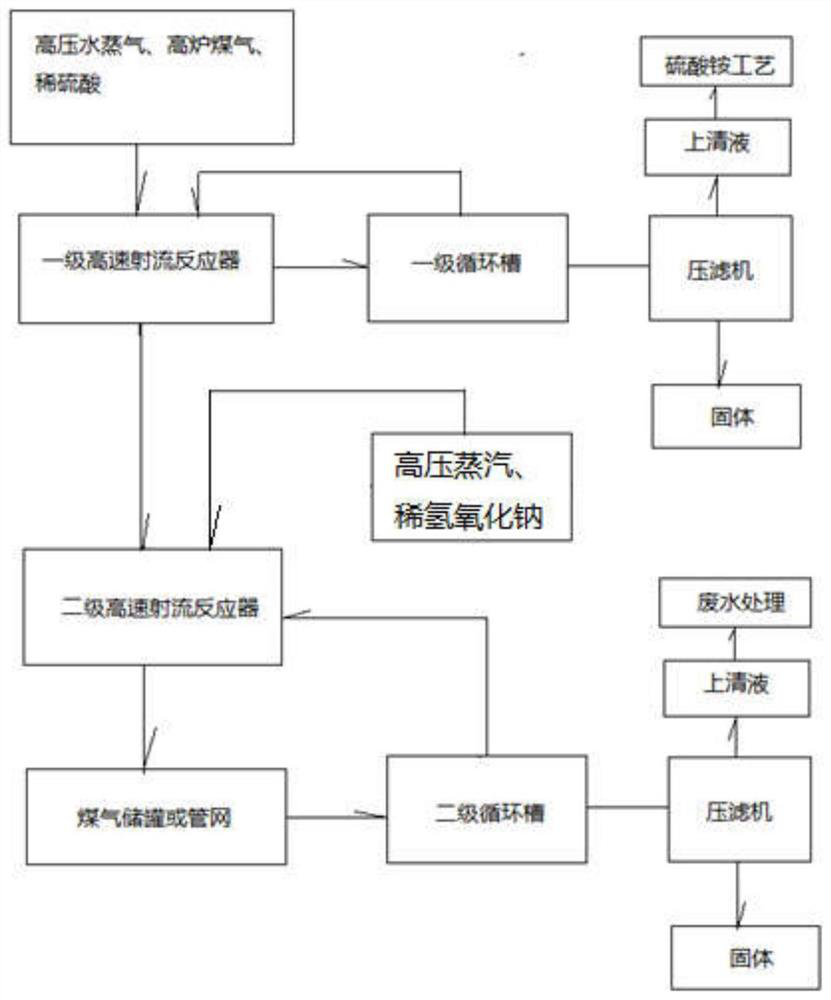

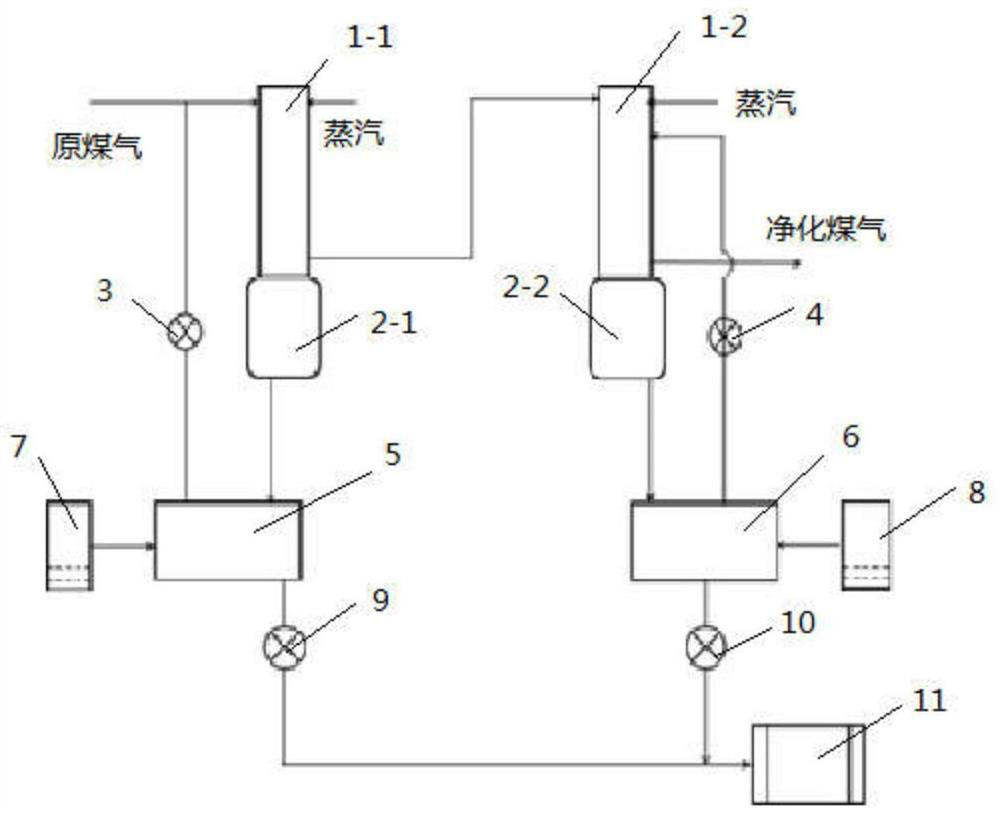

[0048] See attached figure 1 , 2 , 3, 4, blast furnace gas ammonium chloride high-speed jet flow purification method of the present invention, comprises the following steps:

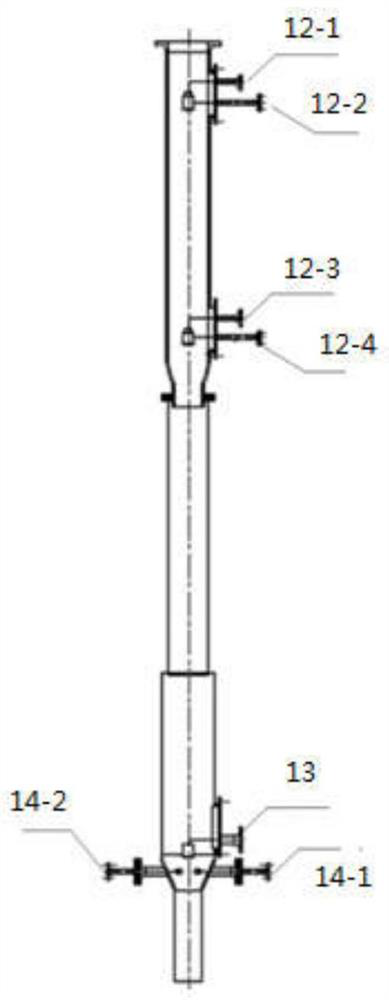

[0049] Introduce about 0.4MPa high-pressure steam and dilute sulfuric acid solution to the upper part of the first-level high-speed jet reactor (1-1). In the first-level high-speed jet reactor (1-1), first use the gas-liquid two-phase flow nozzle (12- The high-pressure steam in 1, 12-2) atomizes the dilute sulfuric acid solution and sprays dilute sulfuric acid absorption liquid particles with particles between 10-20 μm to the first-stage high-speed jet reactor (1-1), dilute sulfuric acid absorption The liquid and liquid particles absorb and wash the pollutants (ammonium chloride, ammonia) in the blast furnace gas, and at the same time, the high-pressure steam condenses the ammonium chloride particles in the blast furnace gas during the condensation process, making them grow up and dissolve in water. Th...

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 is: the dosage of dilute sodium hydroxide is 0.55kg / h per 1000 cubic meters of gas, and the mass fraction is 10%; the dosage of dilute sulfuric acid is 0.35kg per 1000 cubic meters of gas / h, the mass fraction is 10%; the amount of high-pressure steam feeding is 50kg / h per 1000 cubic meters of gas; when the mass concentration of the first dilute sulfuric acid absorption liquid in the primary circulation tank reaches 10% of the initial concentration, the output is open circuit to the filter press for solid-liquid separation; when the mass concentration of the first dilute sodium hydroxide absorption liquid in the secondary circulation tank reaches 10% of the initial concentration, it is output to the filter press for solid-liquid separation in an open circuit.

[0059] In embodiment 2, pass into the blast furnace gas flow rate 8000Nm in the high-speed jet reactor 3 / h, containing ammonia 20mg / Nm 3 , hydrogen chloride ...

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 1 is: the dosage of dilute sodium hydroxide is 0.60kg / h per 1000 cubic meters of gas, and the mass fraction is 10%; the dosage of dilute sulfuric acid is 0.36kg per 1000 cubic meters of gas / h, the mass fraction is 10%; the amount of high-pressure steam feeding is 80kg / h per 1000 cubic meters of gas; the mass concentration of the first dilute sulfuric acid absorption liquid in the primary circulation tank reaches 10% of the initial concentration, and the output is open circuit to the filter press for solid-liquid separation; when the mass concentration of the first dilute sodium hydroxide absorption liquid in the secondary circulation tank reaches 10% of the initial concentration, it is output to the filter press for solid-liquid separation in an open circuit.

[0062] In embodiment 3, pass into the blast furnace gas flow rate 9000Nm in the high-speed jet reactor 3 / h, containing ammonia 25mg / Nm 3 , hydrogen chloride 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com