A method for replacing the bottom brick of the coke oven carbonization chamber

A carbonization chamber furnace and carbonization chamber technology, applied in the direction of preventing/repairing the leakage of bricks, can solve the problems of difficult coke pushing, secondary damage to the furnace body, large coke pushing current, etc., and achieve the effect of ensuring a stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

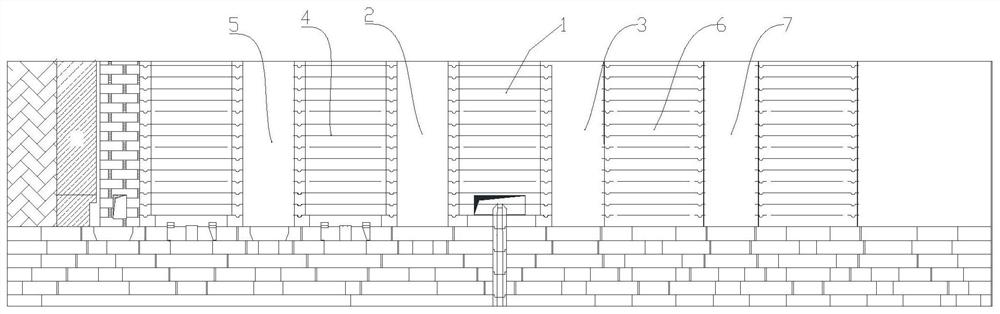

[0044] like figure 1 As shown, taking the replacement of the bottom brick of No. 5 carbonization chamber 1 of JN60 type coke oven as an example, the specific implementation method is:

[0045] A. Set No. 4 carbonization chamber 4 and No. 6 carbonization chamber 6 adjacent to No. 5 carbonization chamber 1 of the coke oven to be repaired as a buffer furnace, and start to control the combustion of No. 5 combustion chamber 2 and No. 6 at the end of coking in No. 5 carbonization chamber 1 Room 3 temperature, gradually turn down the addition and subtraction cock. After the coke pushing in No. 5 carbonization chamber 1 is completed, the bridge pipe is closed with water-seal flap, and the rising pipe cover is closed to control the standard temperature of the coke oven machine side to not be lower than 1200°C and the standard temperature of the coke side to be not lower than 1250°C. In principle, follow the steps below to control the temperature:

[0046] a. Infrared on-line thermome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com