Monitoring method for hydraulic fracturing based on distributed optical fiber sound monitoring and distributed optical fiber temperature monitoring

A distributed optical fiber and hydraulic fracturing technology, applied in surveying, earthmoving, wellbore/well components, etc., can solve the problems of difficult multi-stage fracturing artificial fracture process monitoring, poor accuracy, and high implementation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

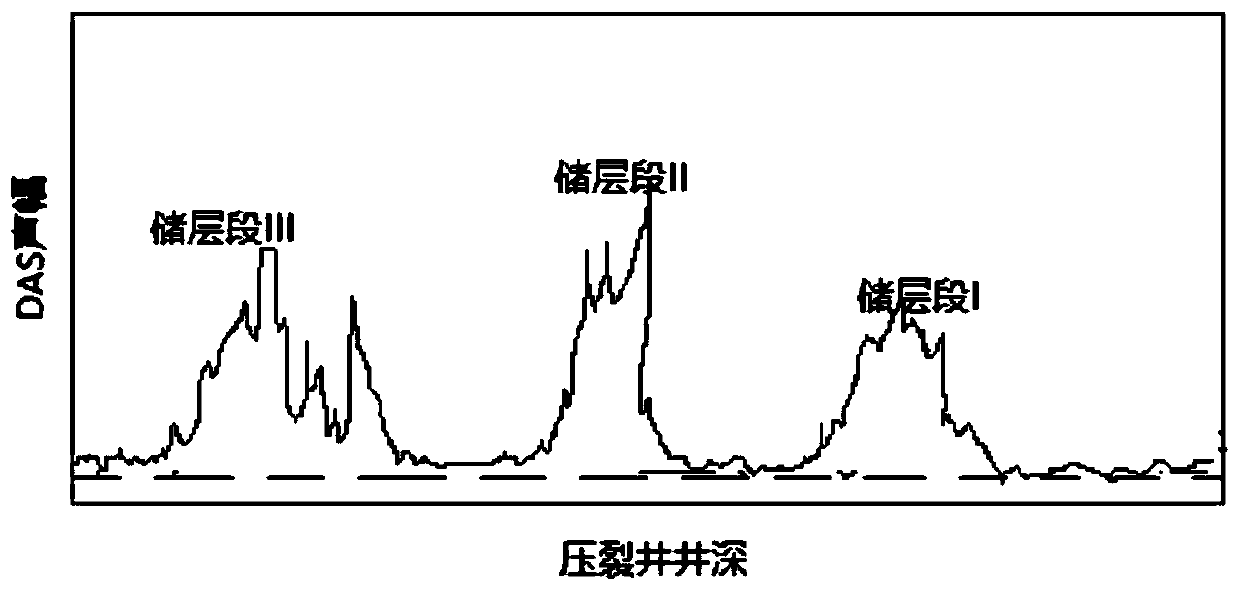

[0073] A hydraulic fracturing monitoring method based on distributed optical fiber sound monitoring and distributed optical fiber temperature monitoring, using the sound signal reflected from the downhole by the single-mode acoustic sensing fiber and the temperature signal reflected from the downhole by using the multi-mode temperature-sensing optical fiber for processing Finally, it is obtained: the fracturing status of each fracturing section during the hydraulic fracturing process, and / or the real-time flow rate of each fracturing section during the post-fracturing production process, and / or the water content;

[0074] The module for processing the sound signal and temperature signal is a DAS / DTS hydraulic fracturing monitoring and interpretation module including a data preprocessing module, a fracturing process interpretation module and a post-fracturing production interpretation module; the DAS / DTS hydraulic fracturing monitor 7 has a spatial resolution of 1 meter, a respo...

Embodiment 2

[0100] A hydraulic fracturing monitoring method based on distributed optical fiber sound monitoring and distributed optical fiber temperature monitoring as described in Example 1, the difference is that the sound signal reflected from the downhole by the single-mode acoustic sensing optical fiber and the multi-mode sensing The temperature signal reflected back from the downhole by the temperature optical fiber is processed to obtain: the real-time flow rate of each fracturing layer during the post-fracturing production process, and / or the real-time flow rate of each fracturing layer during the post-fracturing production process, and / or water content The implementation method is as follows:

[0101] 2-4) Calculate the fluid flow rate and proppant volume entering each decompressed fracture interval:

[0102] Add all the areas of the graphs surrounded by the curves corresponding to the fractured intervals in the "Waterfall Diagram" to calculate the total graph area; use the curve...

Embodiment 3

[0122] In order to realize the monitoring method described in embodiments 1 and 2, the hardware installation method for collecting sound signals and temperature signals is as follows:

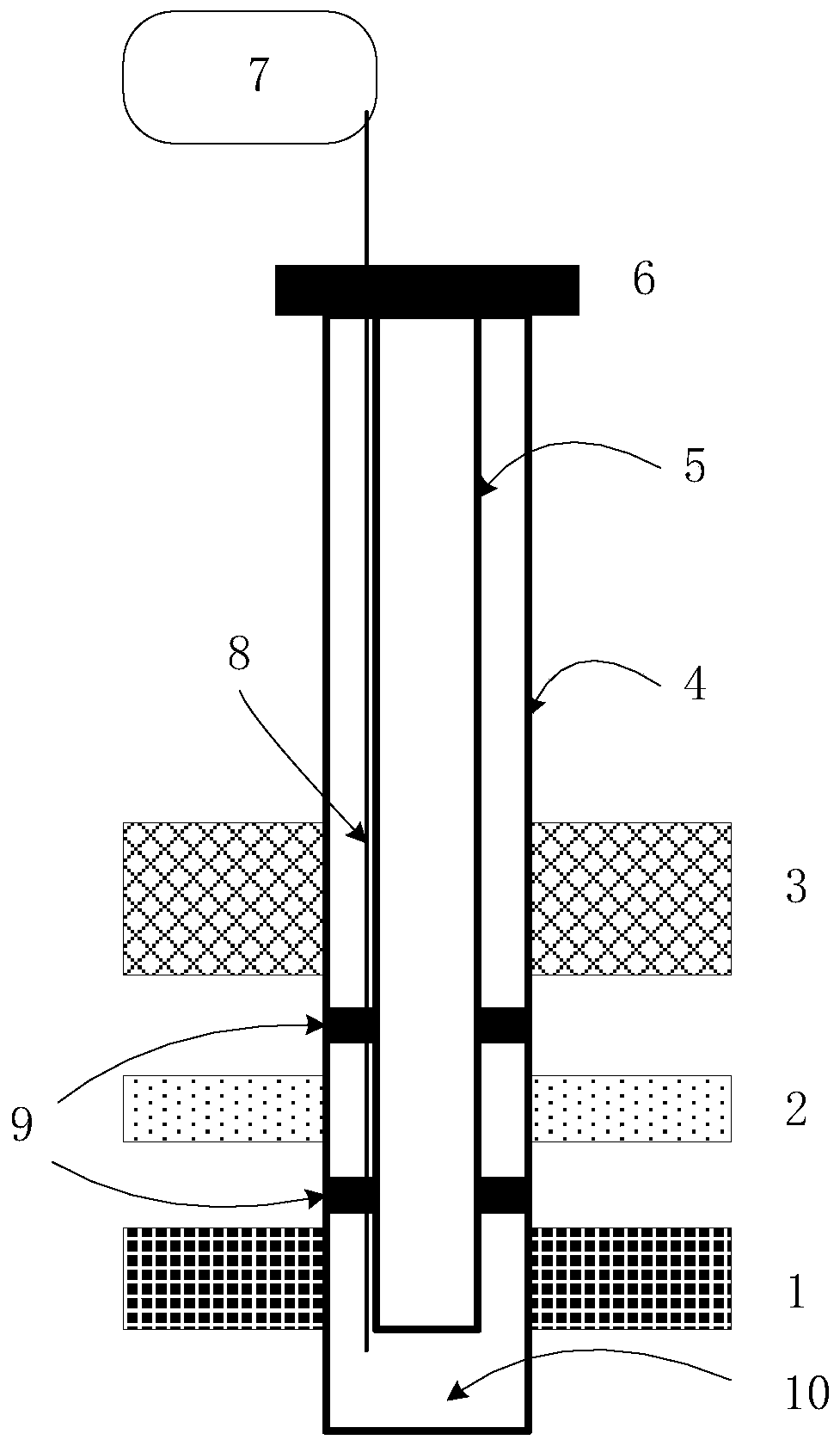

[0123] Using DAS / DTS hydraulic fracturing monitor 7 and armored optical cable 8, the DAS / DTS hydraulic fracturing monitor 7 is placed on the ground and directly connected to armored optical cable 8; armored optical cable 8 is attached to the fracturing pipe string Or on the production string 5, run into the well with the fracturing string or the production string 5 during the hydraulic fracturing process or the post-fracturing production process;

[0124] The armored optical cable 8 is made of a plurality of single-mode sound-sensing optical fibers and a plurality of multi-mode temperature-sensing optical fibers armored by seamless stainless steel tubes or armored by decomposable aluminum alloy; the plurality of single-mode The acoustic optical fiber can be 1, 2, 5, or arbitrarily many; the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com