Vacuum glass air exhaust method and air exhaust device

A technology of vacuum glass and air extraction device, which is applied in the direction of pump device, liquid variable capacity machine, variable capacity pump components, etc., which can solve the problems of reduced quality of vacuum glass products, affecting the efficiency of pumping, shortening the service life, etc., to achieve Guaranteed processing quality and service life, wide application range, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

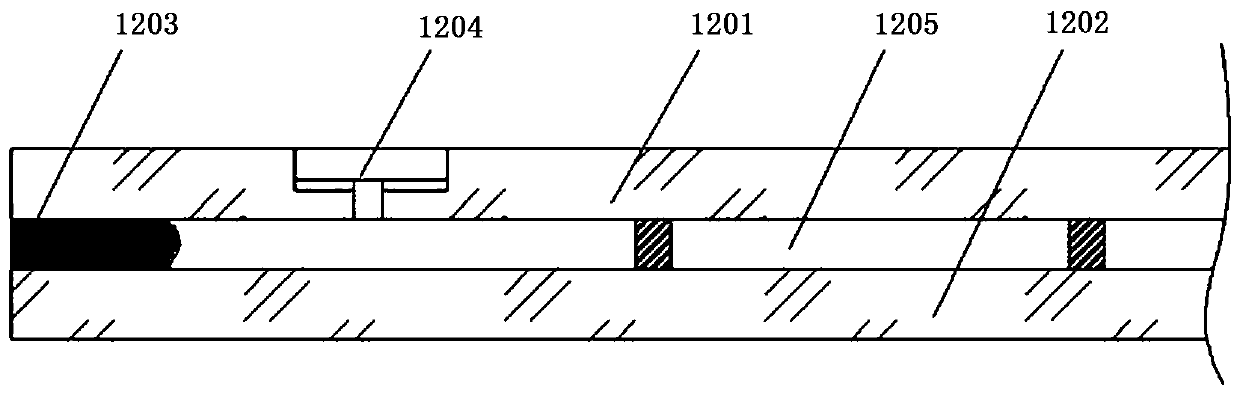

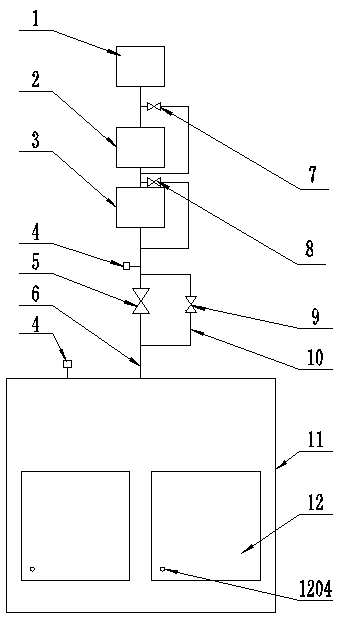

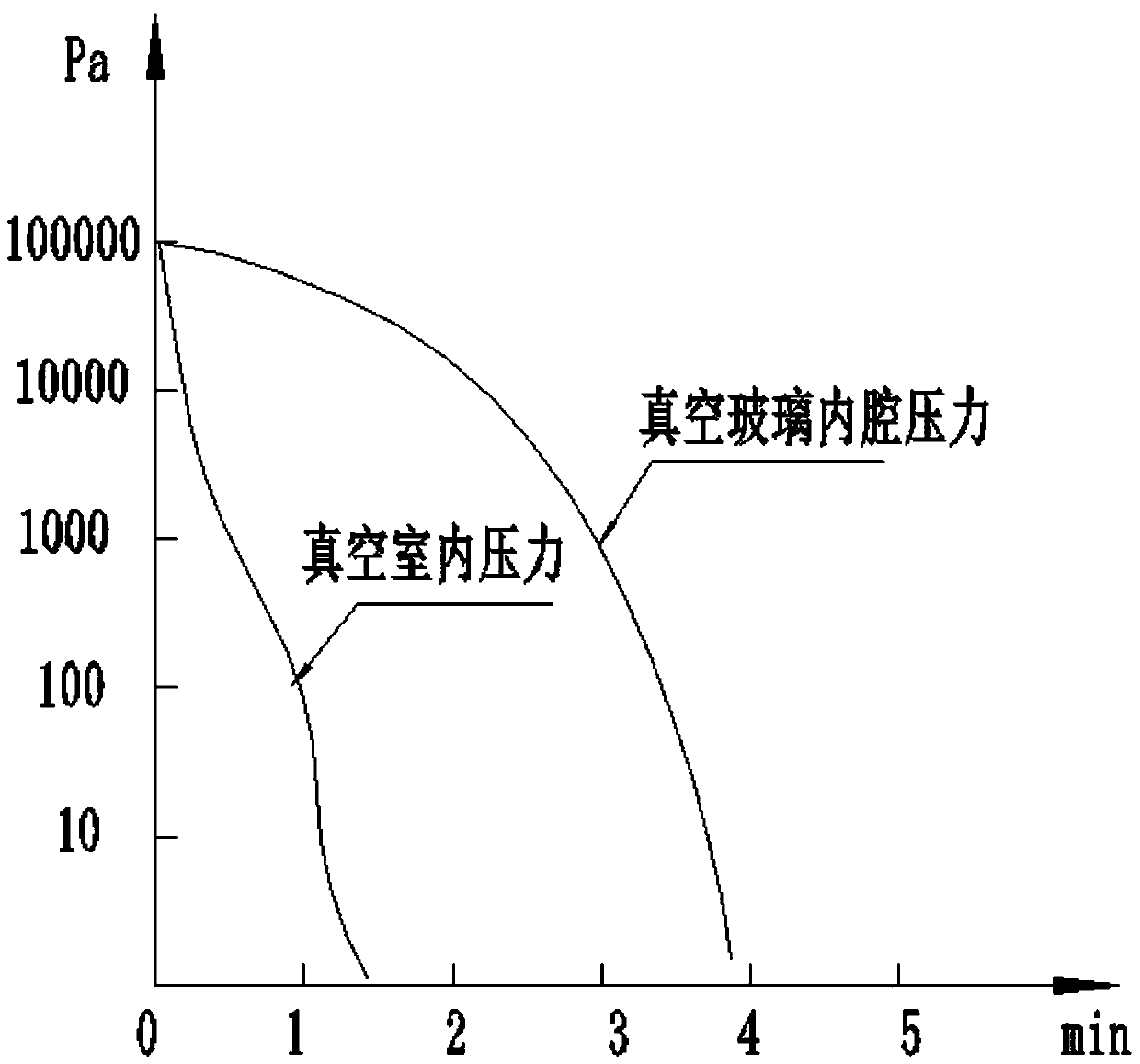

[0040] As shown in the figure, a vacuum glass suction device includes a main suction pipeline 6 and a branch line suction pipeline 10 arranged on the main suction pipeline 6. The main suction pipeline 6 is connected to the suction pump, and the suction pump selects the rotary vane Pump 1, Roots pump group 2 and molecular pump 3, the rotary vane pump 1 is connected to the main suction pipeline 6 through the main pipe, the Roots pump group 2 and molecular pump 3 are connected to the main pipe, and on the main pipe side A first bypass pipe and a second bypass pipe are provided. The first bypass pipe is provided with a valve Ⅱ7, which is connected in parallel with the Roots pump unit 2. The second bypass pipe is provided with a valve Ⅲ8, a valve Ⅲ8 and The molecular pumps 3 are connected in parallel; the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com