Novel aviation kerosene coalescence separator

A technology of coalescing separator and jet fuel, which is applied in the field of separators and new jet fuel coalescing separators. Reduced service life and other issues, to avoid abnormal pressure difference of coalescer separator, reduce manual operation, and achieve long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further explained below, but the present invention is not limited to the following examples.

[0017] In response to problems in the prior art, a combined coal aggregation separator that can be monitored in real time and automatically exhaust gas can reduce a large number of artificial work, effectively monitor gas aggregation in real - time and achieve automatic exhaust, Avoiding the differential differences and corruption of the coalescery and the filtering damage, there is a big practical significance.

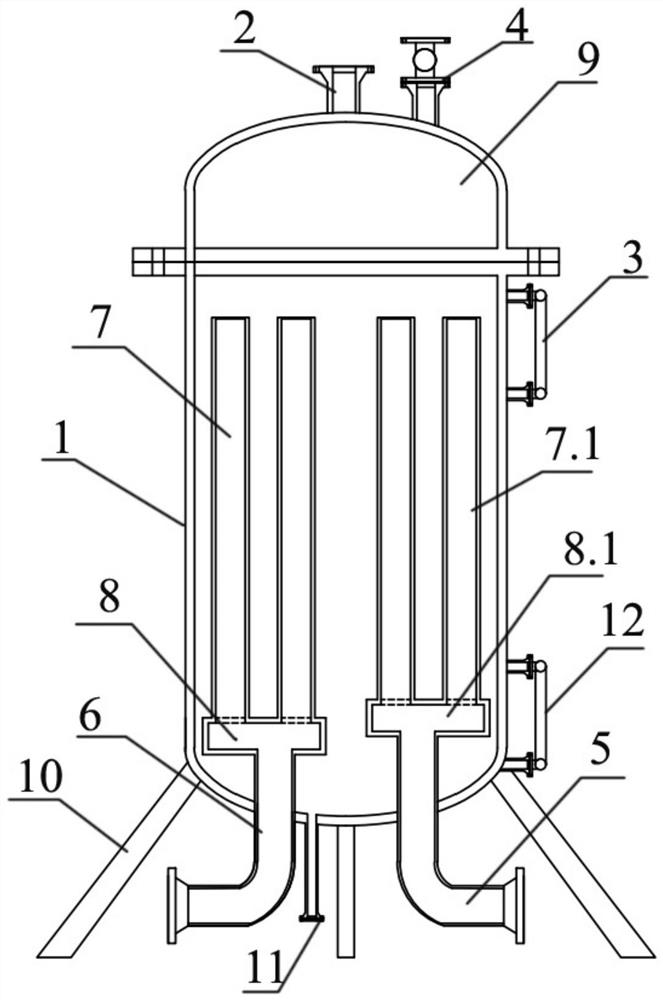

[0018] like figure 1 A specific embodiment of a new type of aircraft coal coalescery separator is shown. This embodiment includes a navigation coal coal coalescery, including a cylindrical body 1, and the upper end of the cylinder 1 is provided with a safety valve interface 2, an automatic row. The air valve 4, the automatic exhaust valve 4 is connected to the torch system by a flange, and the lower end of the cylinder 1 is connected to the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com