Engine exhaust flow calculation method and system

A technology of exhaust flow and calculation method, which is applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems of large number of moving average points, increase of system complexity and price, insufficient dynamic response, etc., to achieve dynamic, High dynamics, the effect of improving the calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

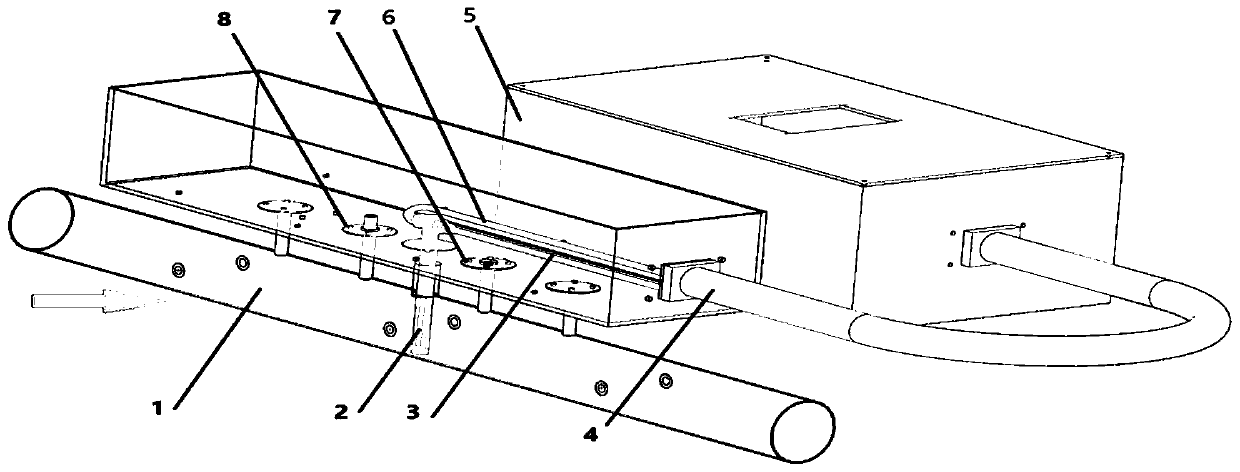

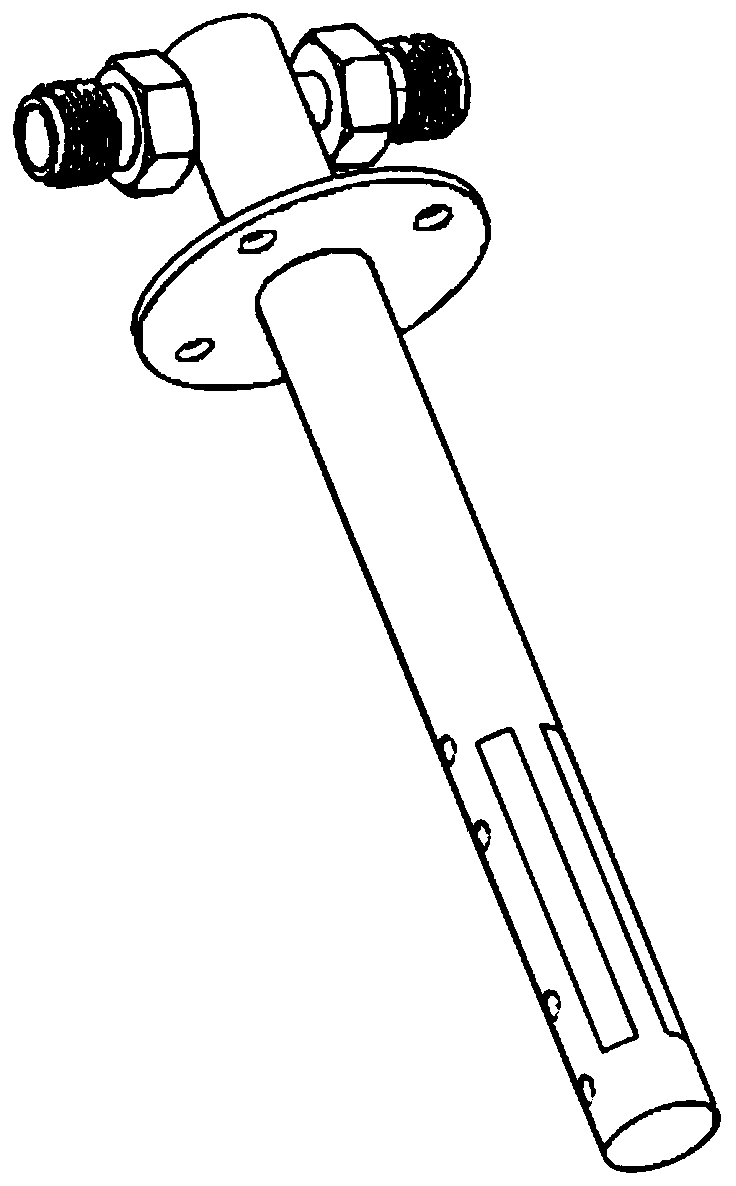

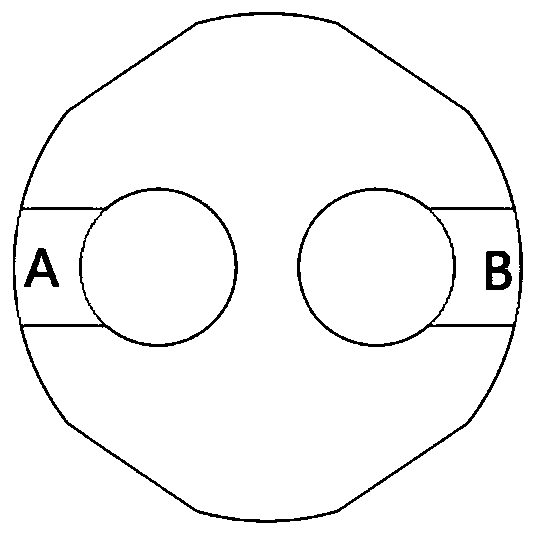

[0038] This embodiment provides an engine exhaust flow calculation system based on the exhaust pressure difference, please refer to the attached figure 1 , the engine exhaust flow calculation system includes a differential pressure acquisition device, a main control device and a rotational speed acquisition device; the differential pressure acquisition device collects current engine exhaust pressure differential data, exhaust temperature data and exhaust absolute pressure data, and transmits To the main control device, the speed acquisition device collects the engine speed data and transmits it to the main control module, and the main control device obtains the current engine exhaust pressure difference data, exhaust temperature data, exhaust absolute pressure data and engine speed data, for The engine exhaust pressure difference data is subjected to nine-point moving average smoothing filter processing, the engine single cycle is calculated according to the speed, the engine s...

Embodiment 2

[0053] This embodiment provides a method for calculating engine exhaust flow based on exhaust pressure difference, which is implemented based on the engine exhaust flow calculation system described in Embodiment 1.

[0054] Please refer to the attached Figure 4 , the engine exhaust flow calculation method based on the exhaust pressure difference comprises the following steps:

[0055] S101. Obtain current engine exhaust pressure differential data, exhaust temperature data, exhaust absolute pressure data, and engine speed data.

[0056] In this embodiment, the current engine exhaust pressure differential data, exhaust temperature data and exhaust absolute pressure data are collected by the differential pressure acquisition device, and transmitted to the main control device.

[0057] In this embodiment, the acquisition of the rotational speed has the following methods:

[0058] (1) Obtain the rotational speed according to the rotational speed sensor equipped with the engine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com