Method for solving burst of photovoltaic vacuum glass and photovoltaic vacuum glass

A vacuum glass and photovoltaic technology, applied in the direction of photovoltaic power generation, renewable energy integration, sustainable buildings, etc., can solve problems such as bursting, affecting product application and industry development, and bursting of photovoltaic vacuum glass to achieve convenient replacement, excellent safety and reliability The effect of high performance and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

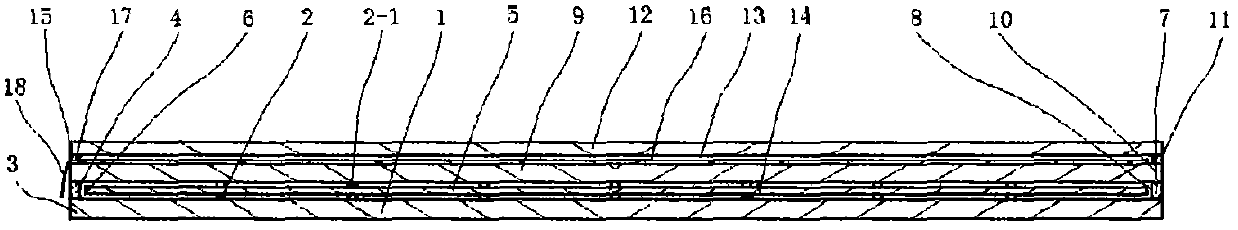

[0028] Embodiment one, according to Figure 1 Shown:

[0029] (1) Arrange pins 2 at corresponding positions on the surface of the inner flat glass 1, and arrange low-temperature sealing material 4 for sealing edges with a melting temperature of 300°C-450°C around the periphery 3 of the inner flat glass.

[0030] (2) Place the heat energy attenuation and dispersion separation layer 5 on the pin 2, and leave a 2mm-10mm thermal expansion gap 8 between the heat energy attenuation and dispersion separation layer periphery 6 and the sealing edge 7 to release the heat energy attenuation and dispersion separation Thermal expansion deformation stress of layer 5 after heating.

[0031] (3) Arrange the second-layer column pins 2-1 at corresponding positions on the surface of the thermal energy attenuation and dispersion separation layer 5, and align the upper and lower column pins.

[0032] (4) Place the outer flat glass 9 on the second-layer pin 2-1, and make the periphery 10 of the o...

Embodiment 2

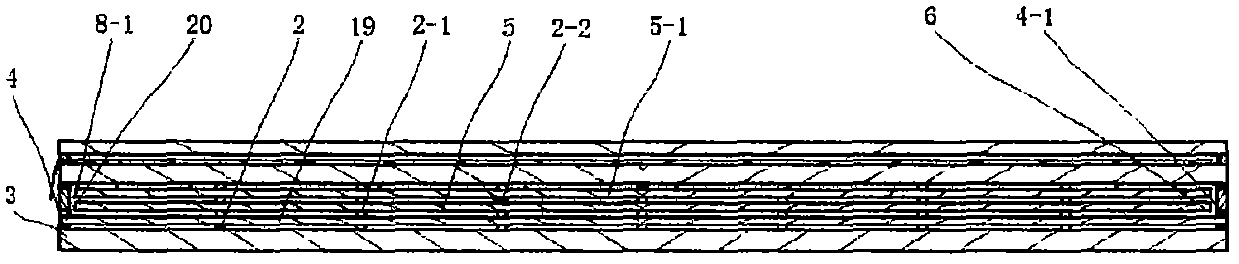

[0037] Embodiment two, according to Figure II Shown:

[0038]According to the method described in Embodiment 1, a vacuum separation layer 19 is first placed on the column pin 2, and the lower surface of the periphery of the vacuum separation layer 20 is fully connected with the sealing edge low-temperature sealing compound 4 arranged on the periphery 3 of the inner flat glass; Arrange the second-layer column pins 2-1 at the corresponding positions of the separation layer 19, and arrange the sealing edge low-temperature sealing material 4-1 with a melting temperature of 300°C-450°C on the upper surface of the periphery 20 of the vacuum separation layer; Place the thermal energy attenuation and dispersion separation layer 5 on the column pin 2-1, and leave a 2mm-10mm thermal expansion gap 8-1 between the periphery of the thermal energy attenuation and dispersion separation layer 6 and the sealing edge low-temperature sealing material 4-1; Three layers of pillar pins 2-2 are ar...

Embodiment 3

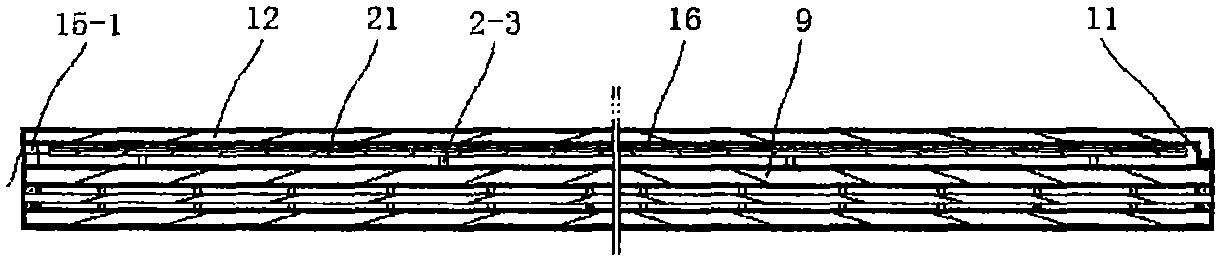

[0039] Embodiment three, according to Figure three Shown:

[0040] After the material assembly is completed according to the method described in Embodiment 1 and 2, a protective glass low-temperature sealing material 11 with a melting temperature of 300°C-450°C is placed on the two or three sides opposite to the outer flat glass 9, and a placement port will be provided. The protective glass 12 of 15-1 and the pin 2-3 of the heat dissipation placement plate 21 are placed on the protective glass low-temperature sealing material 11; then it is made as described in (7) of Embodiment 1; Place the opening 15-1, place the solar cell or battery film 16 on the heat dissipation placement plate 21, seal the placement opening 15-1 with the sealing material 17, and lead the wire 18 out of the sealing material 17, that is, complete the heat dissipation placement The fabrication of a photovoltaic vacuum glass of the plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com