Power cable peeling device

A power cable and cable technology, which is applied to cable installation devices, cable installation, and equipment for dismantling/armored cables, etc., can solve the problems of difficult peeling and low work efficiency, and achieve high cutting efficiency, easy control, Easily adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

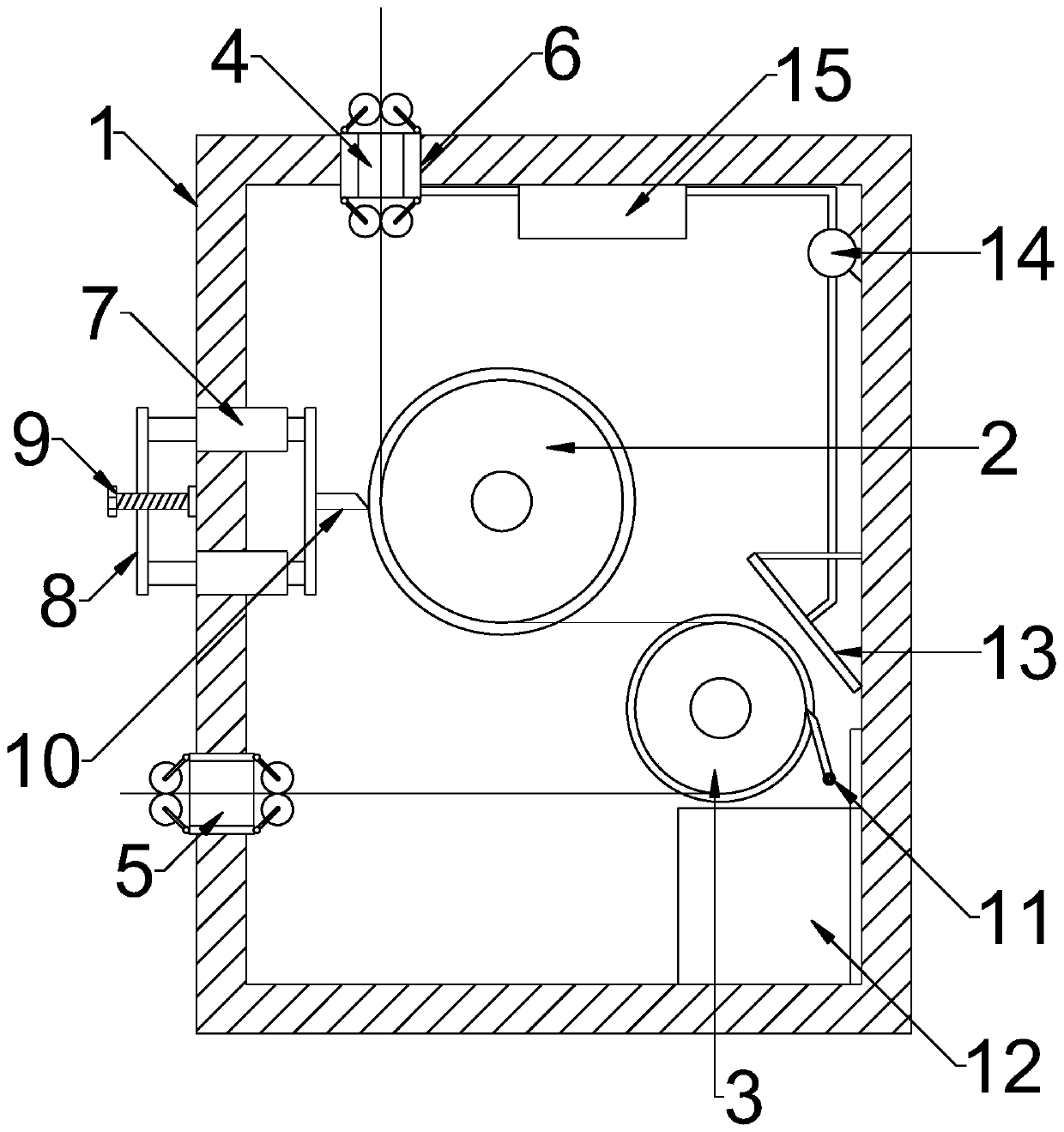

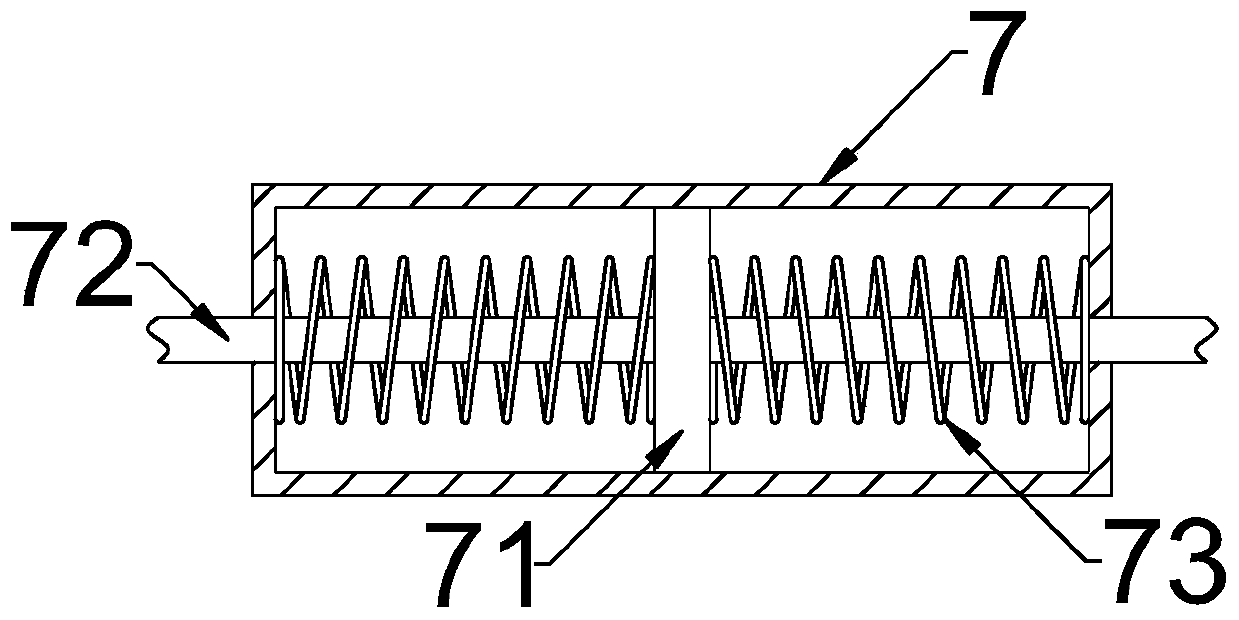

[0023] see Figure 1~3 , in an embodiment of the present invention, a power cable stripping device includes a housing 1, and the inner radial rotation of the housing 1 is provided with a first rotating wheel 2 for supporting the cutting of the cable sheath and for supporting the cable stripping The second rotating wheel 3, the side of the housing 1 is also connected with a cutting structure corresponding to the first rotating wheel 2, and the side of the second rotating wheel 3 in the housing 1 is also connected with a strap 11, The ends of the straps 11 are movably attached to the surface of the second rotating wheel 3 .

[0024] Both the first rotating wheel 2 and the second rotating wheel 3 have a ring-shaped concave surface, and the second rotating wheel 3 is located on the lower side of the first rotating wheel 2; The side wall of the casing 1 above the wheel 2 is provided with an inlet hole 4, and the side wall of the casing 1 corresponding to the left side of the secon...

Embodiment 2

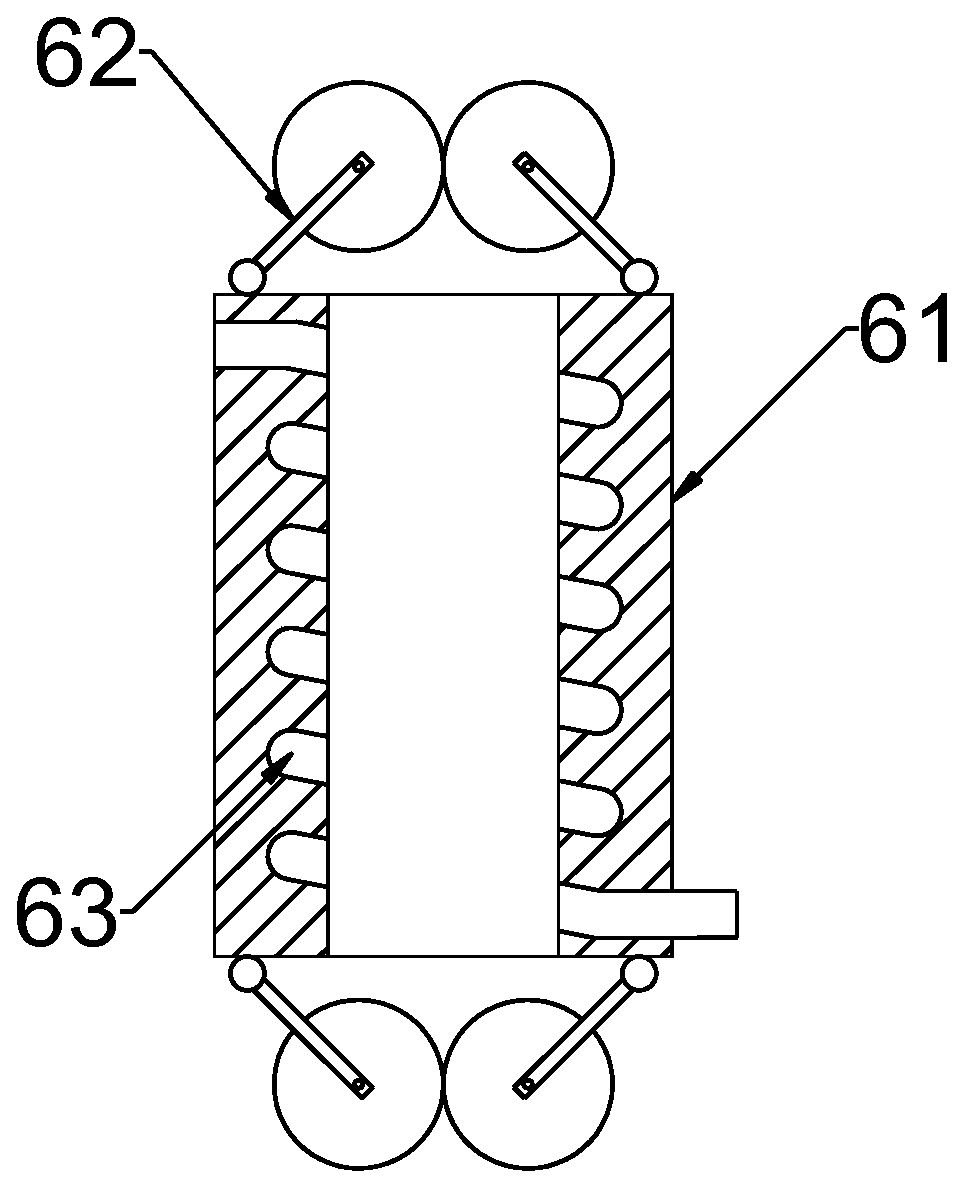

[0029] see figure 1 and 4 , in the embodiment of the present invention, a power cable stripping device, on the basis of embodiment 1, the end of the bush 61 is also connected with an air heating structure, and the air heating structure inlet end is connected with a The air inlet plate 13, the air inlet plate 13 is a hollow plate with through holes evenly distributed on the surface, the opening side of the air inlet plate 13 is opposite to the second rotating wheel 3, and is fixed on the inner wall of the housing 1 by a bracket In this way, the airflow enters and heats through the air inlet plate 13, and then discharges through the bushing 61. When the cable enters, the surface is heated, and the cutting efficiency is higher. After the outer skin is cut, in order to improve the efficiency of peeling, the air inlet plate 13 is The wind generates air flow, and the cold air enters through the air inlet plate 13. When passing through, the cable passing around the second rotating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com