Antimony free composition for laser marking thermoplastic compounds

A thermoplastic polymer, marking technology, applied in the direction of iron compounds, bismuth compounds, replication/marking methods, etc., can solve the problems of complex and expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In order to test the laser marking effect of different formulations, these injection molded panels thus equipped were applied to a laser marking system. For the experiments mentioned, a device from the company Trumpf with a Nd:YAG marking laser with a 20 W laser source (TruMark 3020) was used.

[0042] In order to visually observe the enhanced absorption of the thermoplastic compound, the panels are marked with a so-called "test grid". Along with this change the main laser marking parameters such as marking speed and pulse frequency. When the effect of these different parameters can be seen, the result is a matrix. This helps to find the best settings for the laser and shows the practicability of the system. The more parts of such a test grid exhibit good contrast, the less sensitive the system is to changes in laser settings. To demonstrate the applicability of this test, the bar was also lettered and numbered and barcoded with specific laser parameters, similar to ...

Embodiment 2

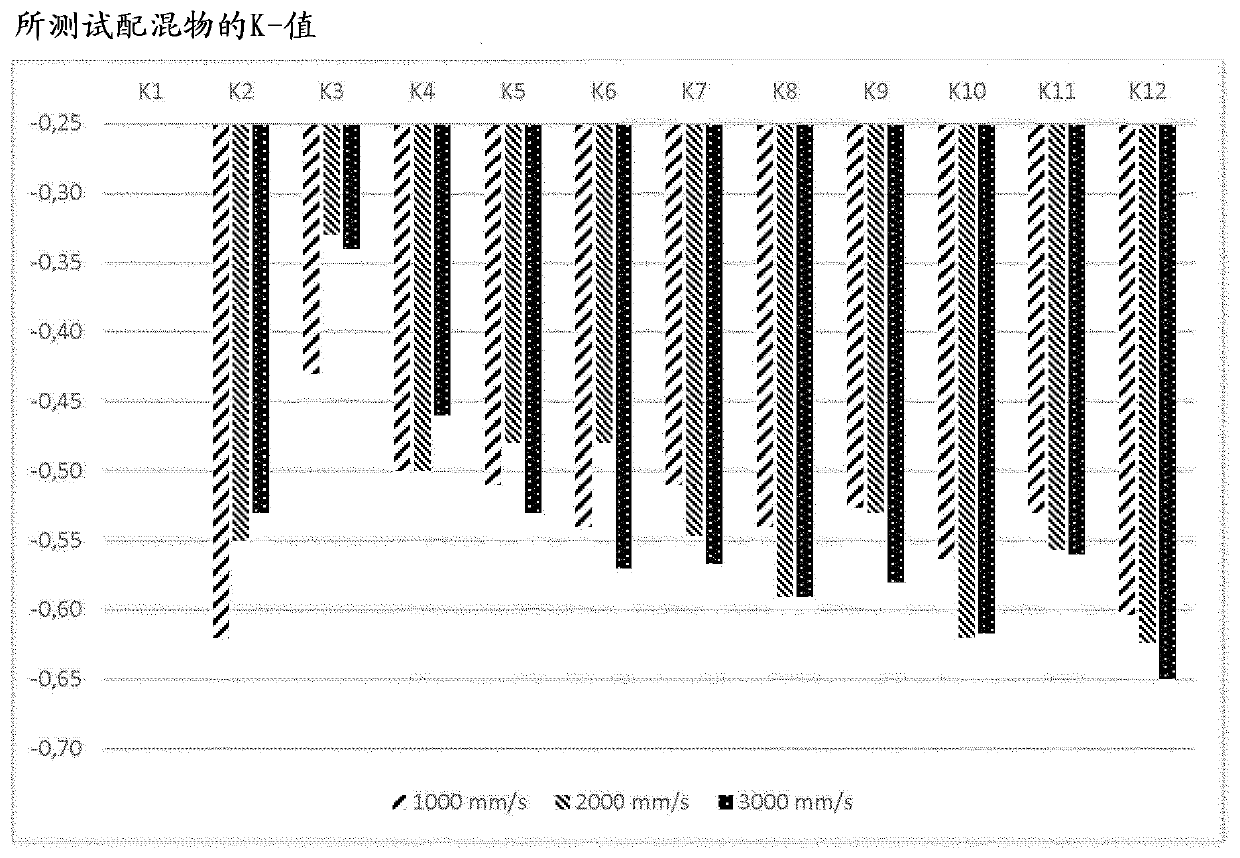

[0050] The different tests were measured by using a ColorLite sph900 device using the same method of making the test specimens as described above. Such devices are capable of measuring so-called K-values (light contrast values). Like the δL* value, the result gives an indication of the quality of the mark, but also identifies light reflections. The lower the value, the better the marker contrast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com