Straw returning cultivation method based on intermittent fallow

A straw and variety technology, applied in the field of straw returning cultivation based on intermittent fallow, can solve the problems of slow decomposition of straw, accelerated soil loss, and unsatisfactory soil fertilization effect, so as to accelerate decomposition, protect black soil layer, and improve The effect of field ventilation and light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention has been popularized and applied in Baoquanling and Hailin City, Heilongjiang Province, wherein Baoquanling is the arable land of white pulp soil, and Hailin City is the arable land of carbonate meadow soil. Field farming, specifically includes the following steps:

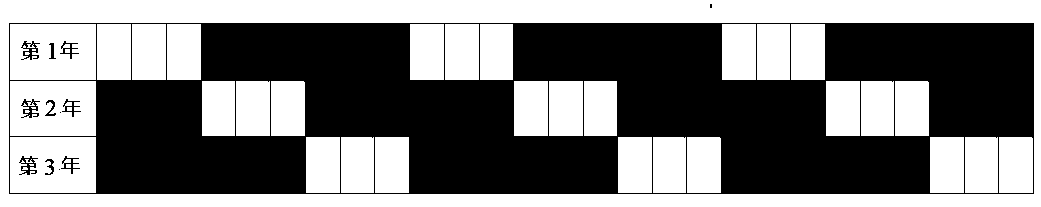

[0025] a. Divide the cultivated land into a number of cultivation zones by row, each cultivation zone has 9 rows, and divide each cultivation zone into a straw returning fallow area and a planting area by row, wherein, the straw returning fallow area is 3 rows, and the planting area The area is 6 rows.

[0026] b. After the harvest of corn in the autumn of the first year, smash all the corn stalks harvested in the tillage belt to less than 10cm in length, then sweep and collect the straw to the fallow area where the straw is returned to the field, and spread it on the surface of the fallow area where the straw is returned to the field .

[0027] c. In the 6-row planting area, use a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com