Press-open type spraying execution mechanism

A technology of actuators and nozzles, applied in fire rescue and other directions, can solve the problems of long lag time of nozzle opening, inability to start spraying, effect discount, etc., to achieve more diversified system design, system working stability and safety improvement, manufacturing cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

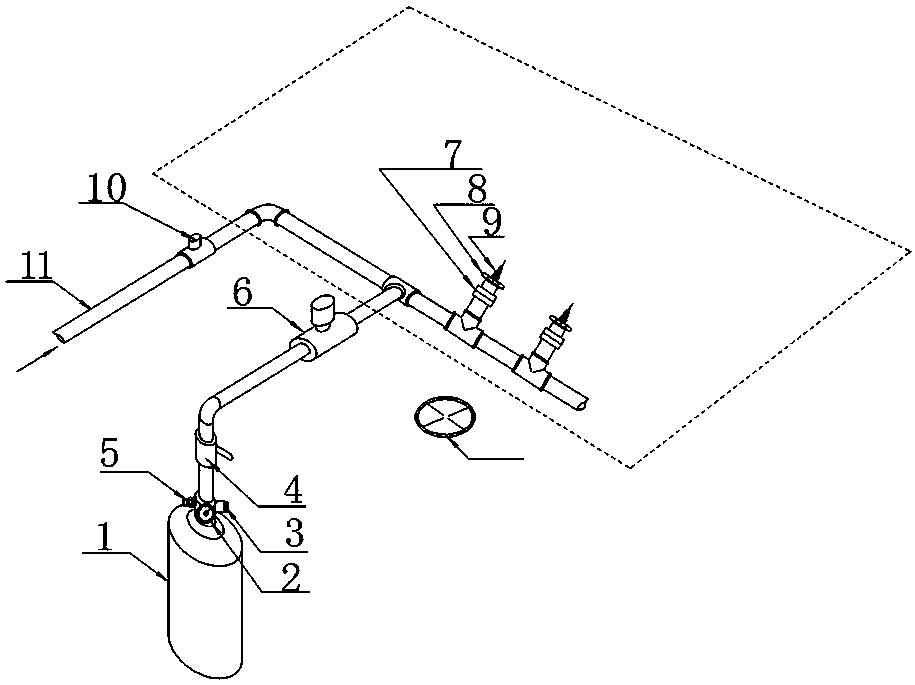

[0015] The present application will be described below through examples. like figure 1 As shown, the present invention provides a pressure-opening type spraying actuator, the structure mainly includes: a spray system and an energy storage tank 1; wherein, the tank body of the energy storage tank 1 is equipped with an inflation valve 5, a safety valve 3, an electric contact The pressure gauge 2 and the manual valve 4 are used to monitor the pressure in the tank and the low-pressure early warning. The manual valve 4 is connected to the high-speed solenoid valve 6, and the high-speed solenoid valve 6 is connected to the fire-fighting pipeline 11 through the pipeline. The fire-fighting water pipes are in parallel, and the high-speed solenoid valve 6 is the same as the fire-fighting pipeline 11. In the sprinkler system, there is a nozzle at the end of the pipeline, and a stainless steel sealing piece 7 is installed in front of the nozzle. There is a connecting piece 8 between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com