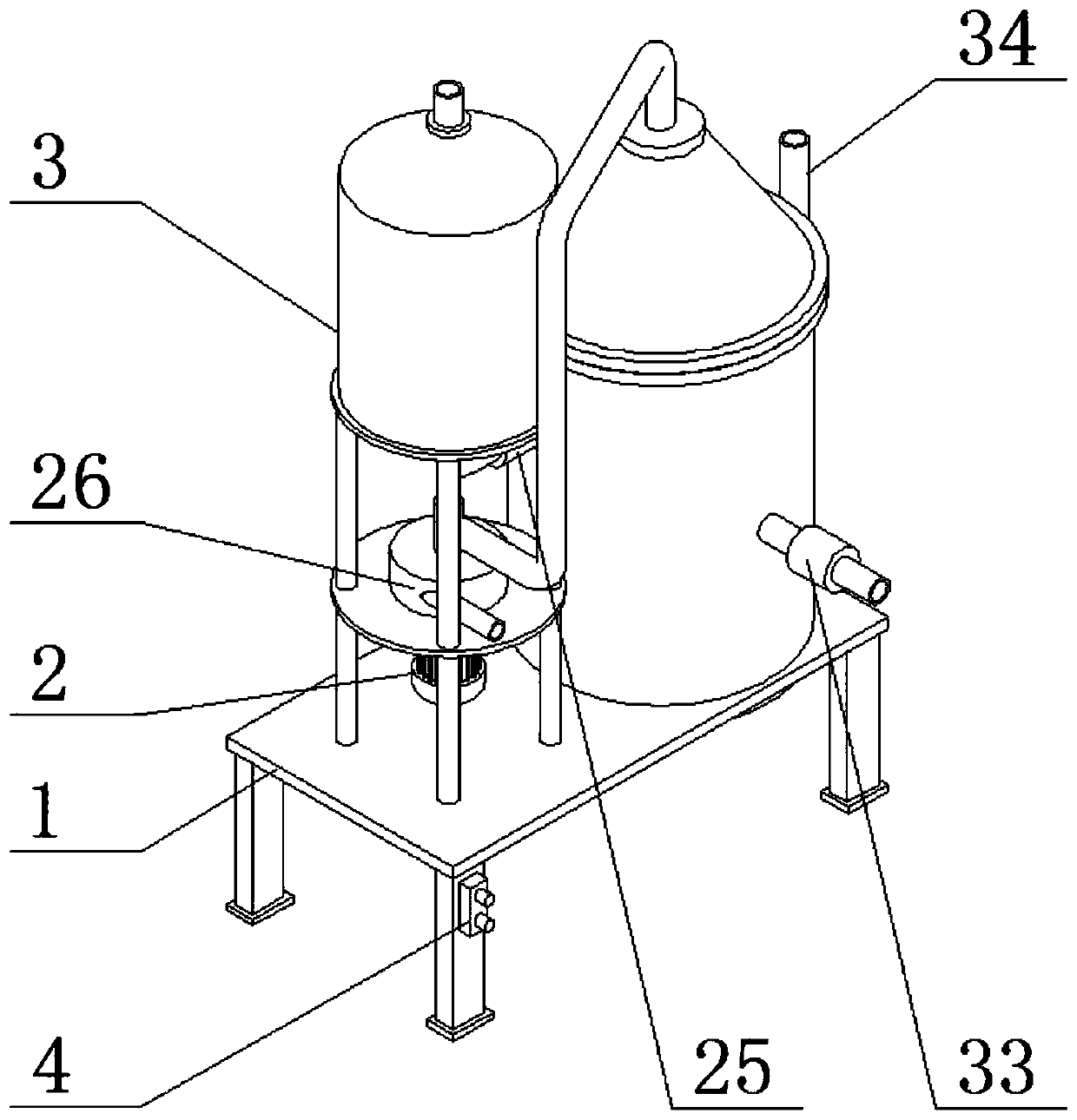

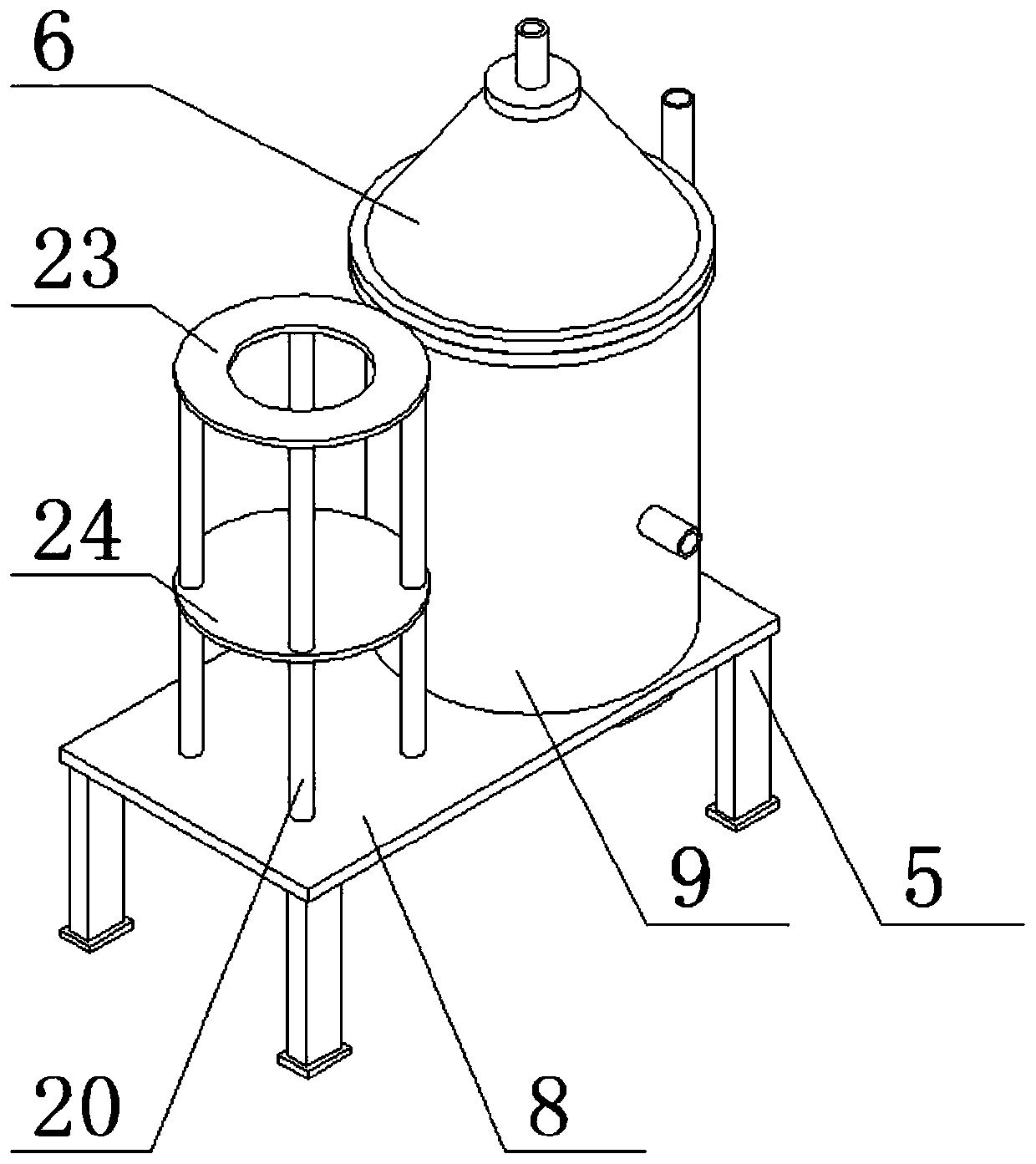

Industrial circulating water rapid sedimentation device

An industrial circulating water and settling device technology, which is applied to the feed/discharge device of the settling tank, sedimentation separation, water/sewage treatment, etc., can solve the problems of reduced purification efficiency, slow cooling speed, and reduced service life of purification membranes , to achieve the effect of increasing the collection amount, accelerating the rapid sedimentation process, and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

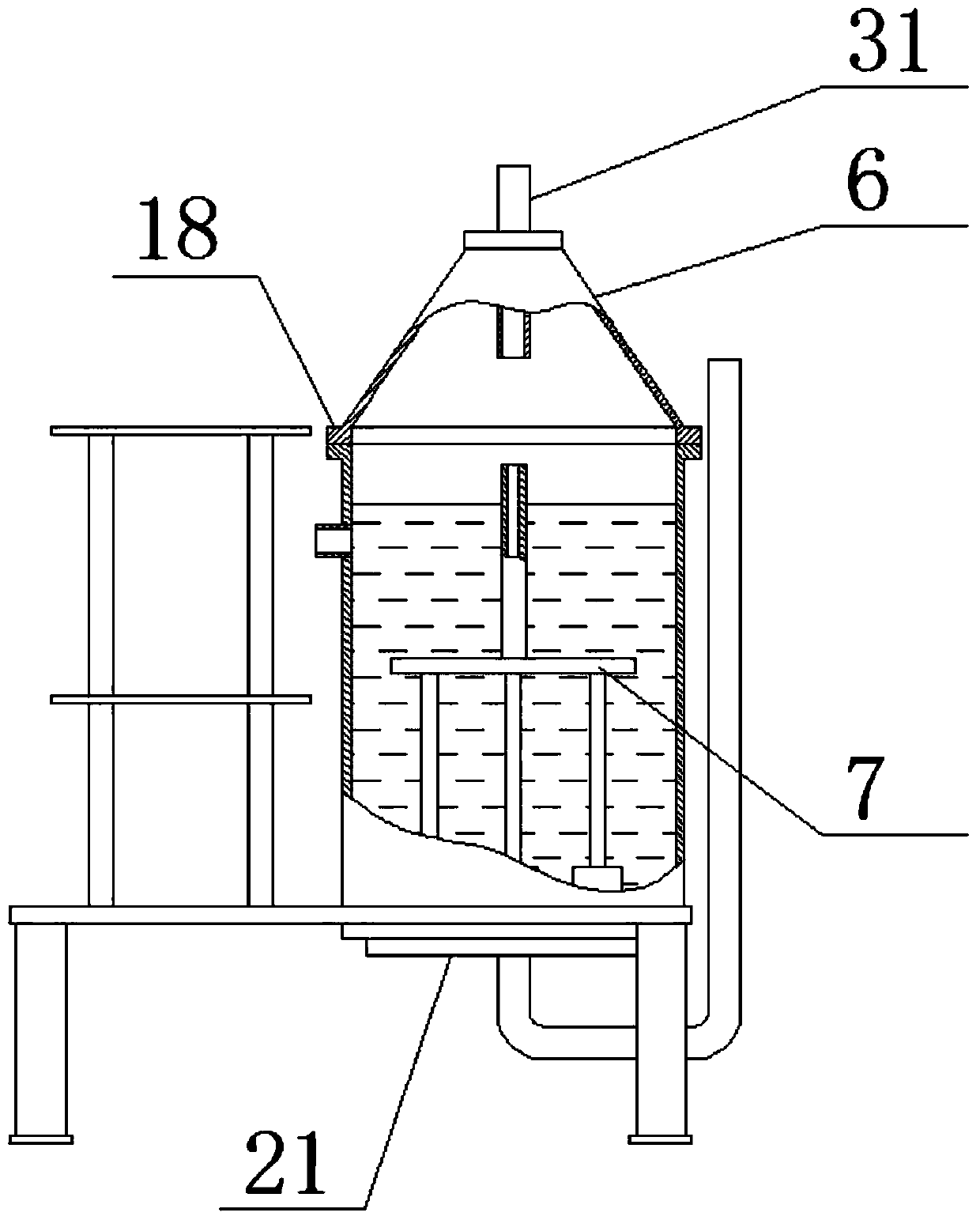

[0032] As a preferred embodiment of the present invention, the side wall of the stitching tube 15 is penetrated with a water tank, and a circular shaft 27 is welded in the water tank, and a wave-shaped swing plate 28 is set on the circular shaft 27. .

[0033] As a preferred embodiment of the present invention, a flow collecting cavity 29 is opened in the flow collecting plate 11 , and the flow collecting cavity 29 communicates with the delivery pipe 12 and the water suction pipe 13 .

[0034] As a preferred embodiment of the present invention, an air supply chamber 30 is opened in the air supply tray 21, and a water channel is opened on the side wall of the bottom of the air supply tank 22, and the air supply chamber 30 is passed through the water channel and the air supply channel. The air tank 22 is connected, the air supply tank 22 is coaxial with the confluence cover 16 , and an air inlet pipe 34 is welded on the bottom side wall of the air supply plate 21 .

[0035] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com