Construction waste recycling device

A technology for recycling and processing construction waste, which is applied in grain processing, solid separation, filtering and sieving, etc. It can solve the problems of not being easy to operate, not being able to significantly improve the efficiency of muck processing, interruption of recycling processing, etc., and achieve a remarkable crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

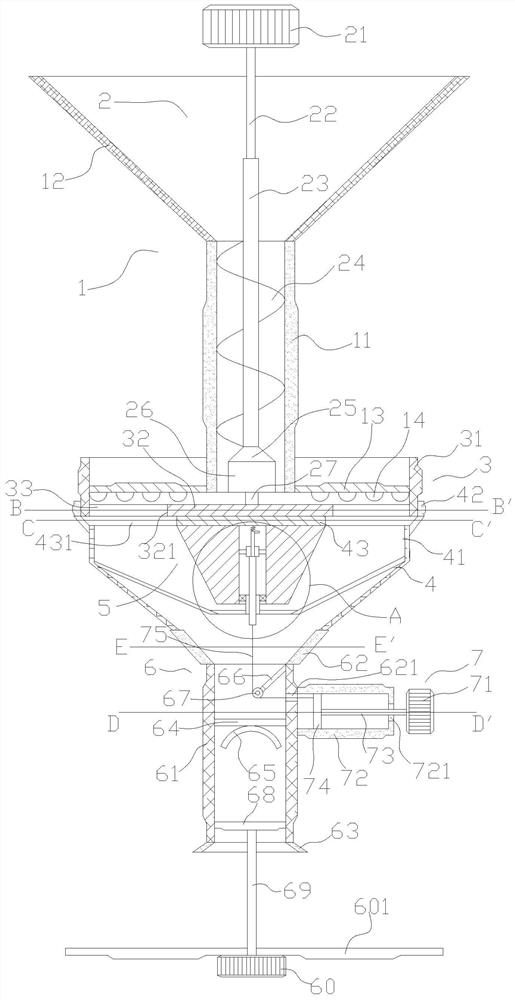

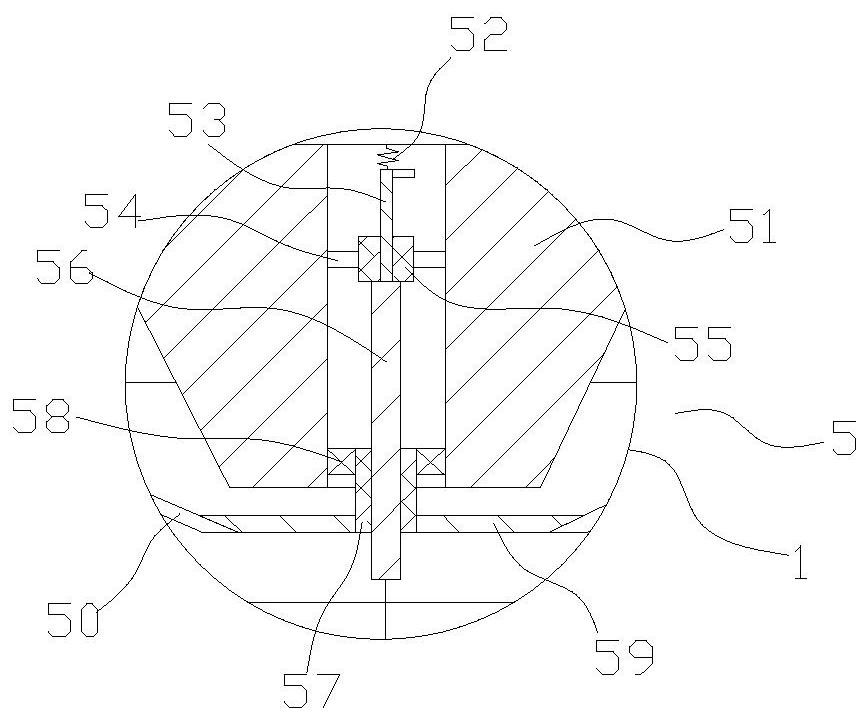

[0035] Such as figure 1 As shown, the construction waste recovery treatment device of the present invention includes a feeding structure 1, a rotating structure 2 arranged on the feeding structure 1, a centralized structure 3 arranged below the feeding structure 1, and a 3, the connecting structure 4 below, the screening structure 5 arranged in the connecting structure 4, the pressing block structure 6 located below the connecting structure 4, and the piston structure 7 arranged on the pressing block structure 6.

[0036] Wherein, the feed structure 1 includes a feed frame 11, a feed hopper 12 arranged above the feed frame 11, the feed frame 11 is preferably a hollow cylinder and the upper and lower surfaces communicate; The hopper 12 is preferably a hollow conical body with a wide top and a narrow bottom. The lower surface of the feed hopper 12 is fixedly connected to the upper surface of the feed frame 11, and the inside of the feed hopper 12 is connected to the feed frame. ...

Embodiment 2

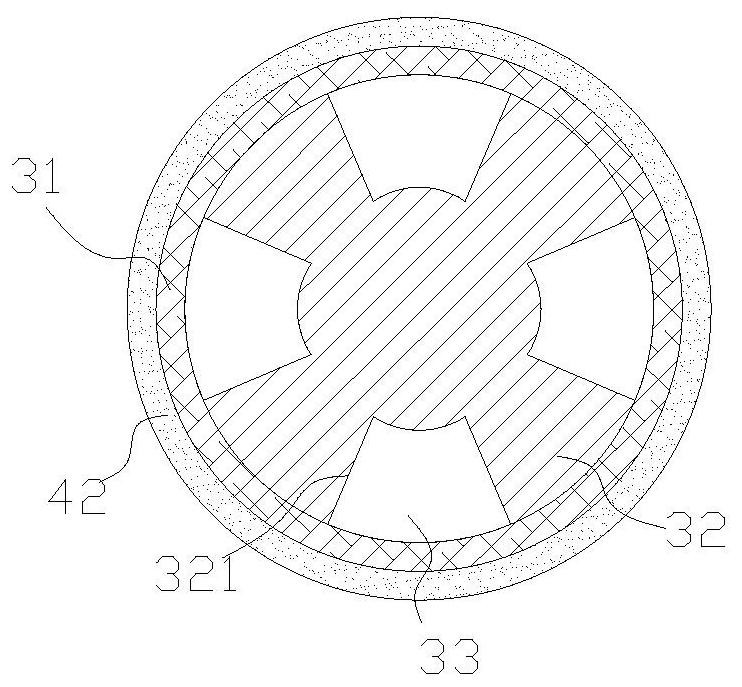

[0040] Such as figure 1 and image 3 As shown, the centralization structure 3 includes a centralization frame 31 , a support plate 32 fixedly connected within the centralization frame 31 , and a plurality of first filter screens 33 disposed on the support plate 32 . The centralizing frame 31 is a hollow cylinder with the upper and lower surfaces connected. The support plate 32 is a circular plate with several through holes on the side, the lower end of the connecting rod 27 is fixedly connected to the center of the support plate 32, and the support plate 32 is provided with a first through hole 321 at its edge. , the number is several and evenly distributed in the circumferential direction. The number of the first filter screen 33 is the same as the number of the first through holes 321, the first filter screen 33 is accommodated in the first through hole 321 and fixedly connected with the support plate 32, the The first filter screen 33 can filter the crushed and ground mu...

Embodiment 3

[0043] A pressing plate 13 is fixedly arranged at the lower end of the feeding frame 11. The pressing plate is a disc-shaped structure whose center is the feeding frame. connection, to realize that the pressing plate and the centralized frame can rotate relatively horizontally, and the vertical direction is limited by the installation groove and will not move; there are several first grinding blocks 14 fixedly connected under the pressing plate 13; Relative movement, that is, relative rotation, so that the waste materials between the support plate 32 , the first filter screen 33 and the pressing plate 13 can be fully pulverized, and the pulverization effect is remarkable.

[0044] All the other are identical with embodiment 2.

[0045] The setting of the feeding structure 1 is convenient for feeding, that is, the user can put the dregs and the like into the feeding hopper 12, which is easy to operate and convenient to use, and the dregs can enter the feeding frame under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com