Trailing cleaning and weld bead shaping device for Overlaying branch pipe weld seam

A technology of shaping device and welding bead, which is applied in the direction of cleaning method using tools, auxiliary device, cleaning method and utensils, etc., which can solve the problems of high structural shape and size requirements, poor follow-up welding treatment, self-adaptation and poor precision, etc. problems, to achieve the effect of easy clamping, fixing and dismounting, saving manpower and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

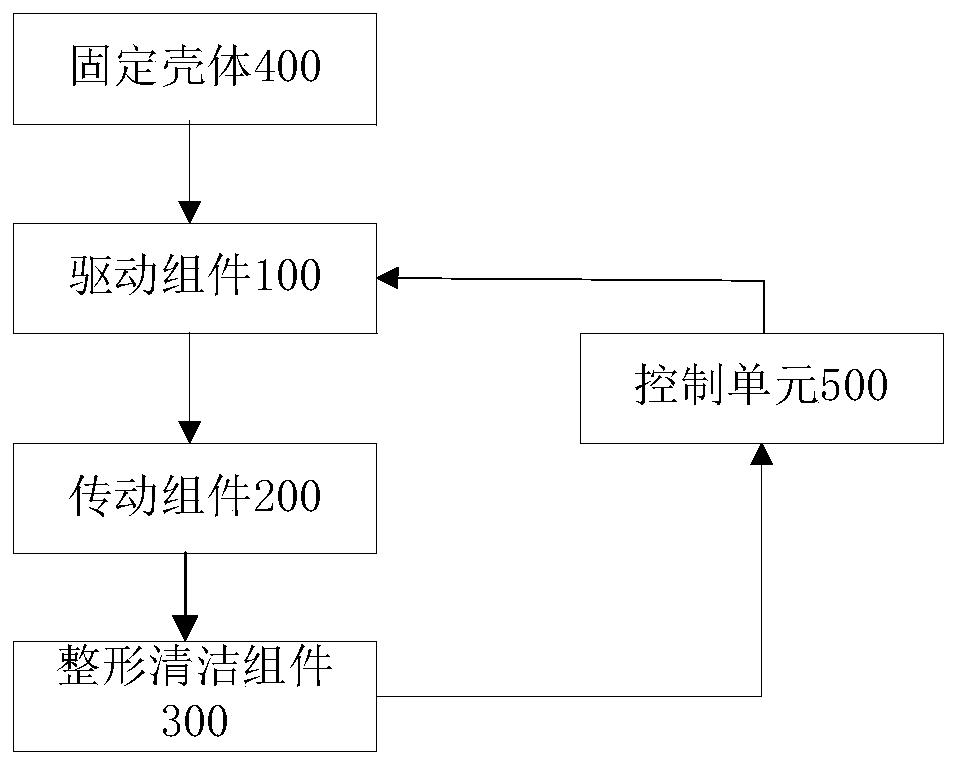

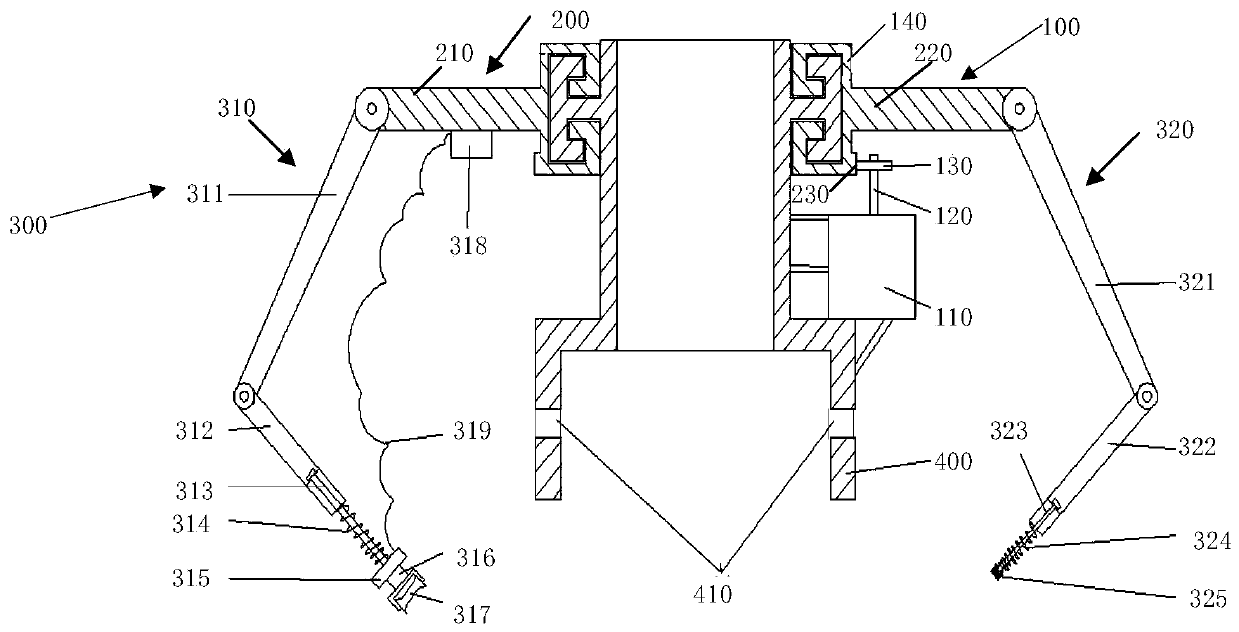

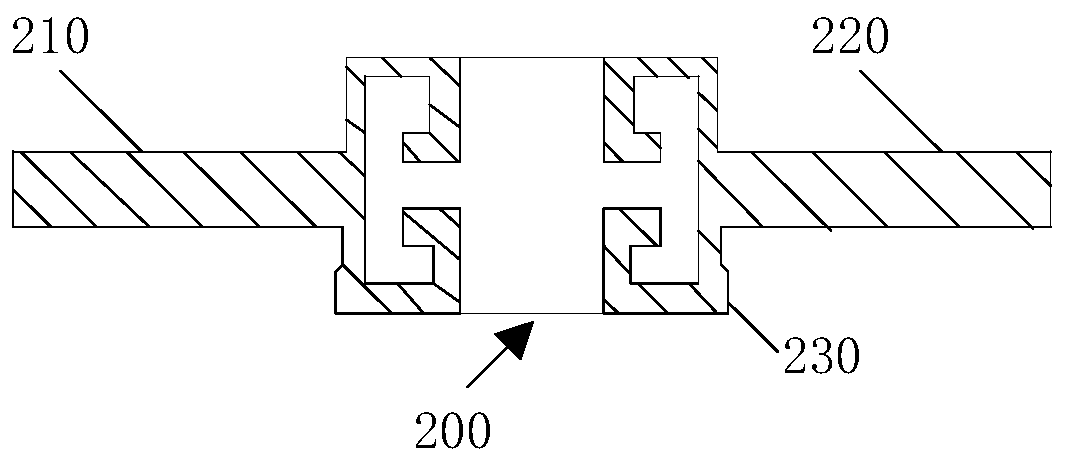

[0028] Such as figure 1As shown, the present invention provides a welding cleaning and bead shaping device for overlay welding of branch pipe welds, including: fixed housing 400, driving assembly 100, transmission assembly 200, shaping and cleaning assembly 300; driving assembly 100 , is movably fixed on the fixed housing 400, and is used to controllably provide driving force for the shaping and cleaning assembly 300; the transmission assembly 200, which is transmissible with the driving assembly 100, is used to transmit the driving force to the shaping and cleaning assembly 300; The shaping and cleaning assembly 300 is connected with the transmission assembly 200 and is used for shaping and / or cleaning the weld bead in the Overlay surfacing area.

[0029] It should be noted that the shaping and cleaning component 300 can shape the weld bead alone, and can also shape and clean the weld bead according to requirements. In practical applications, the shaping and cleaning componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com