Coal gangue separation parallel flexible three-degree-of-freedom robot

A coal gangue and degree of freedom technology, applied in the direction of sorting, manipulators, program control manipulators, etc., can solve the problems of reduced service life of equipment, failure of claws to grasp coal gangue correctly and stably, damage, etc., and achieve the goal of reducing weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

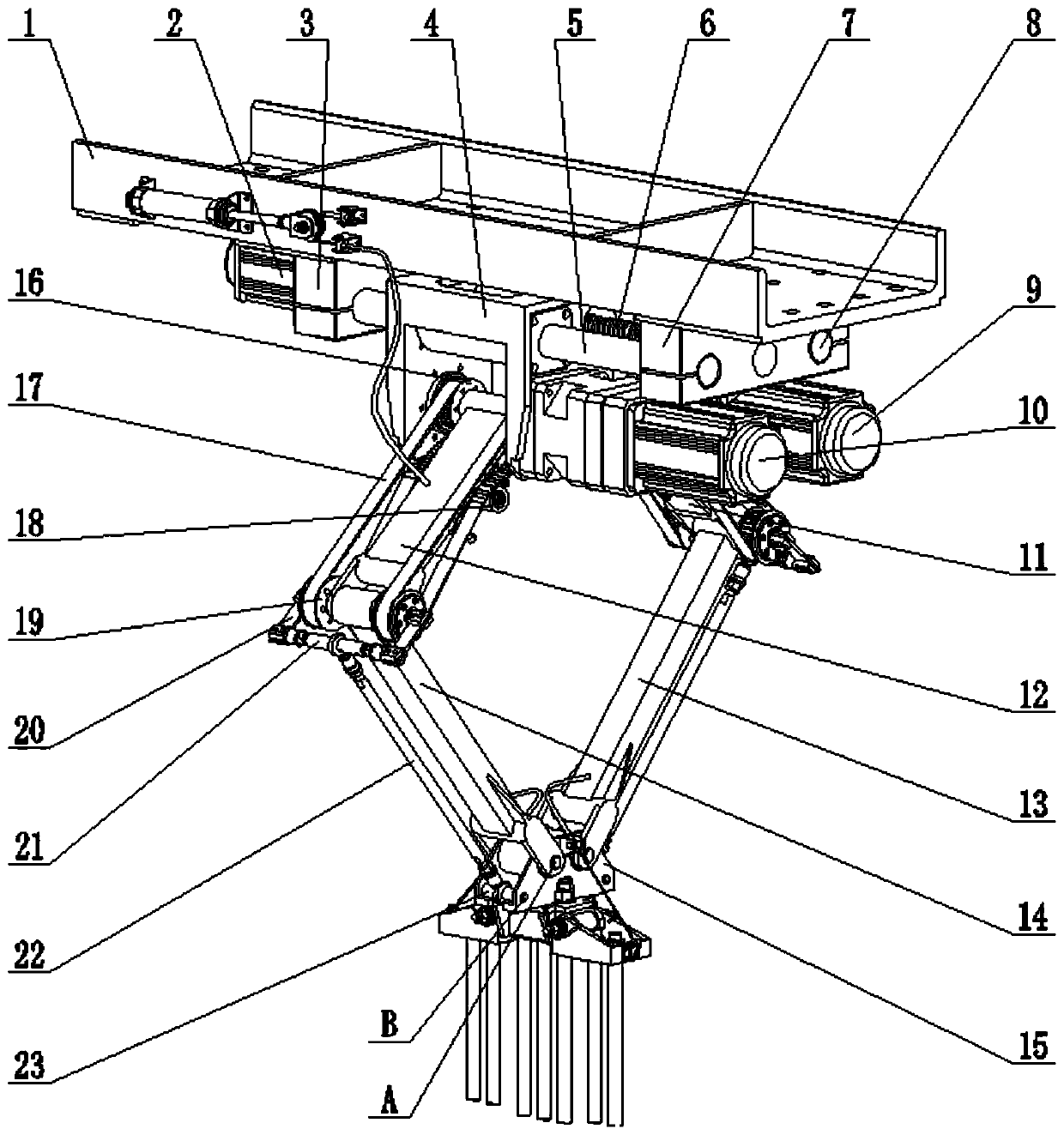

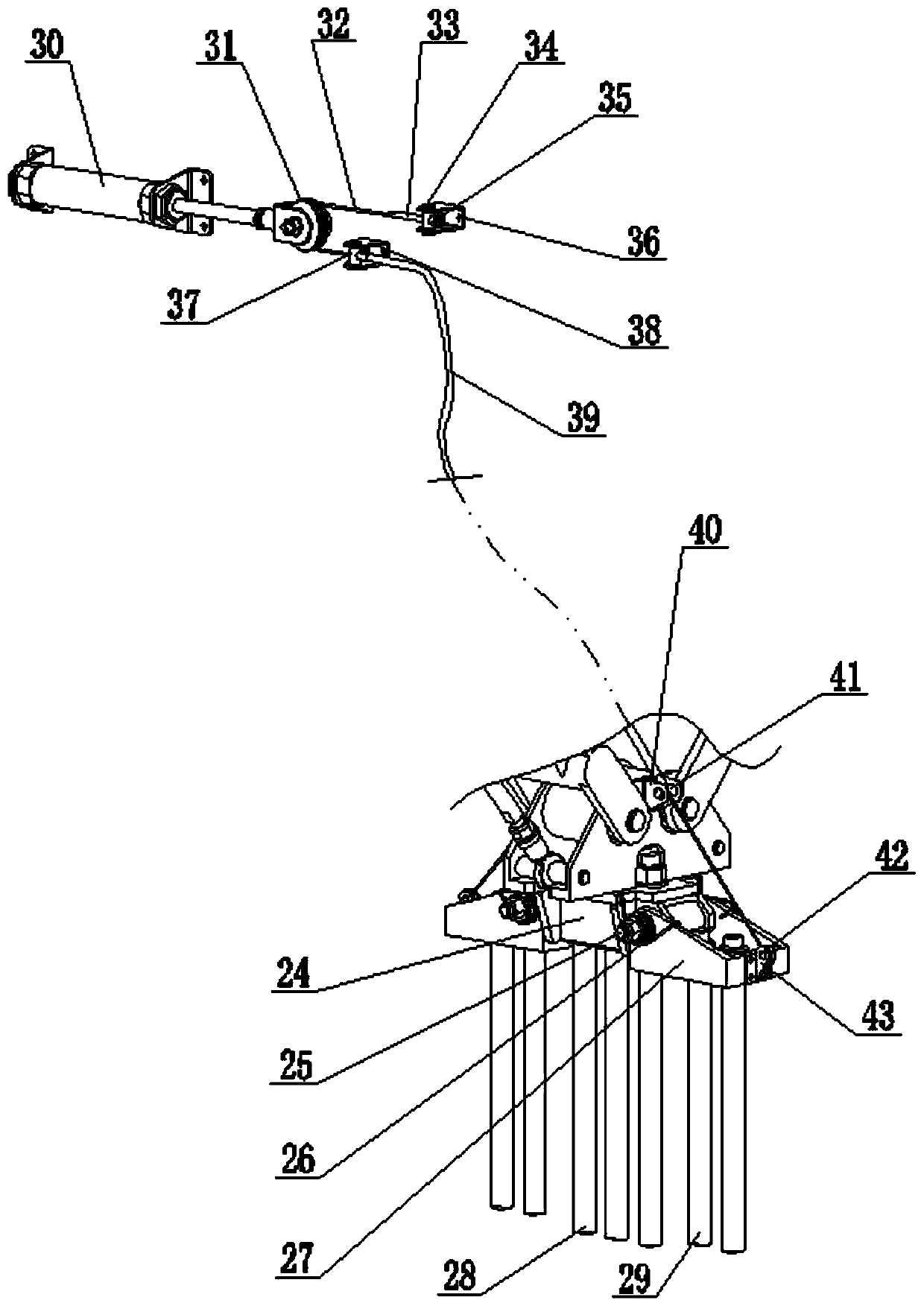

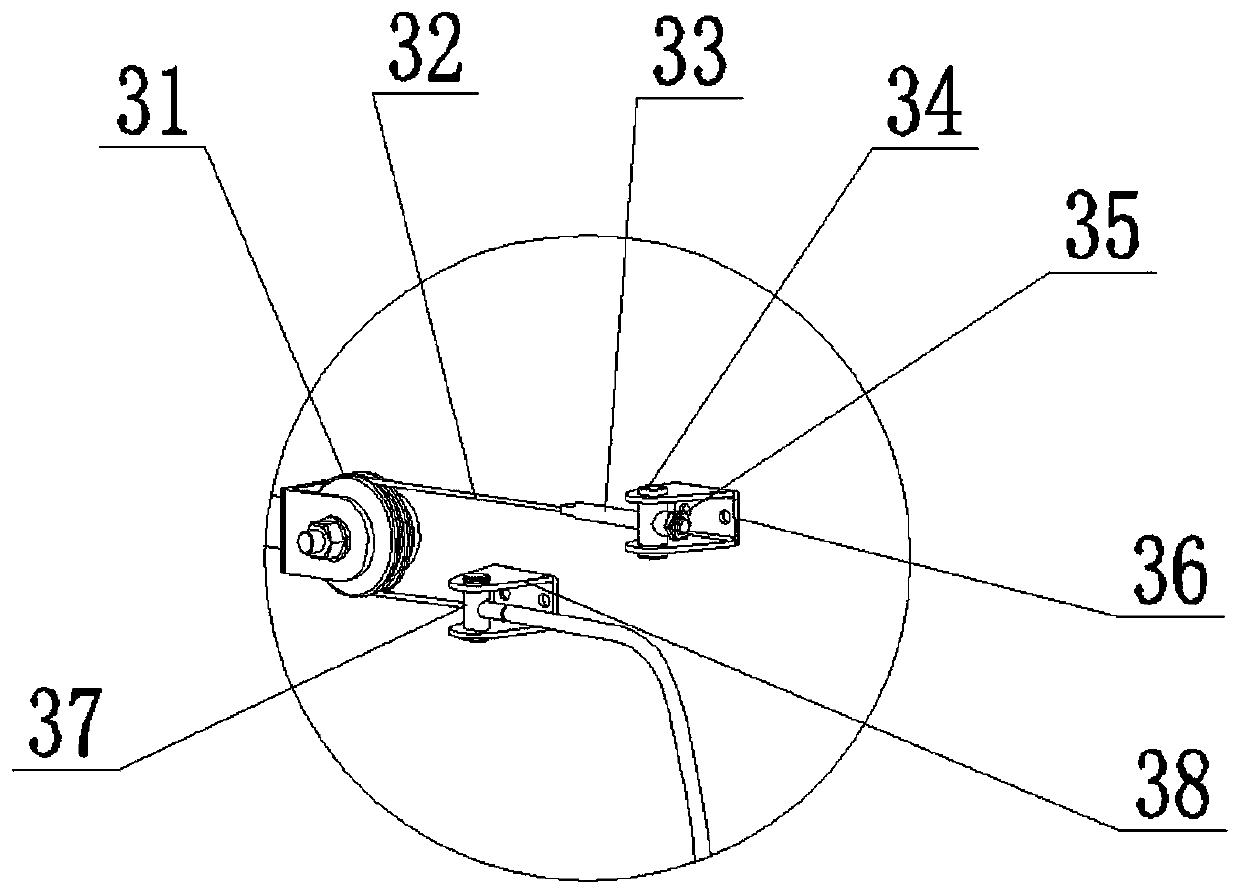

[0032] See attached figure 1 to attach Figure 9 , the present embodiment is a coal gangue sorting parallel flexible three-degree-of-freedom robot, including: a moving mechanism, a parallel mechanical arm mechanism and a claw mechanism.

[0033] The moving mechanism mainly includes: a beam 1, a moving drive servo motor 2, a main supporting base 3, a moving base 4, a left guiding rod 5, a screw nut pair 6, an auxiliary supporting base 7, and a right guiding rod 8. The two ends of the beam 1 are fixed with a main support seat 3 and an auxiliary support seat 7, and two guide rods 5 and 8 are fixed in parallel between the main support seat 3 and the auxiliary support seat 7. At the same time, between the main support seat 3 and the auxiliary support seat Between the 7 and the guide rod, a lead screw nut pair 6 is installed in parallel, and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com