Skid-mounted carbon-dioxide-flooding flow-back gas desulfurization, dehydration and carbon dioxide recovery system

A carbon dioxide and exhaust gas desulfurization technology, applied in gas fuel, inorganic chemistry, carbon compounds, etc., can solve the problems of large investment in desulfurization and decarbonization, small amount of back exhaust gas, and high operating cost, and achieves convenient installation and operation, and reduces processing costs. cost, waste prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

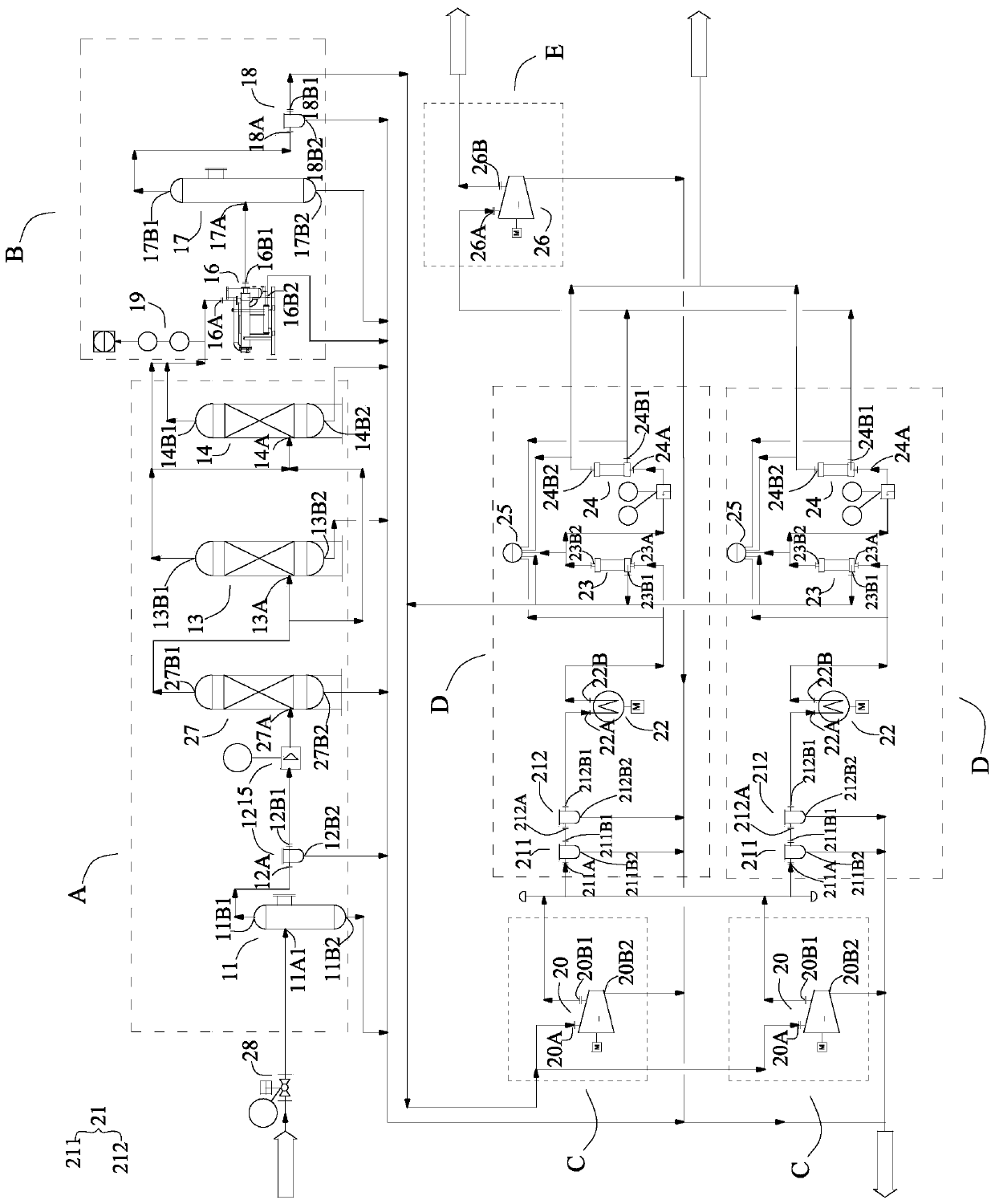

[0075] refer to figure 1 According to the present invention, the skid-mounted carbon dioxide drive-back exhaust gas desulfurization dehydration and carbon dioxide recovery system includes return exhaust gas pretreatment and desulfurization skid A, cold drying skid B, compressor membrane inlet skid C, membrane separation skid D , Carbon dioxide pressurized reinjection skid block E. The cold-drying skid B is connected with the exhaust gas pretreatment and desulfurization skid A through pipelines; the compressor membrane feeding skid C is connected with the cold drying skid B through pipelines; the membrane separation skid D is connected with the compressor membrane feeding skid Block C is connected through pipelines; carbon dioxide pressurized reinjection skid E and membrane separation skid D are connected through pipelines; among them, return exhaust gas first enters return exhaust gas pretreatment and desulfurization skid A for pretreatment and desulfurization, and The return...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap