Ultra-high-strength hot dip galvanizing complex-phase steel and production method thereof

A technology of ultra-high strength and production method, applied in the field of multiphase steel metallurgy, can solve the problems of not comprehensively considering formability, galvanizing performance and welding performance, and achieve significant economic and social benefits, excellent welding performance, and galvanizing performance. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

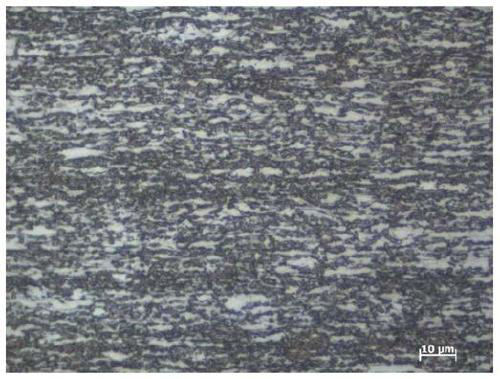

Image

Examples

Embodiment 1

[0041] The high-formability and high-strength hot-dip galvanized dual-phase steel of this embodiment is produced according to the following process:

[0042] (1) Smelting process: C: 0.13%, Si: 0.32%, Mn: 1.95%, Mo: 0.28%, Als: 0.047%, Nb: 0.043%, P: 0.020%, S: 0.005%, N: 0.004% , Ti: 0.053%, and then cast into a slab with a thickness of 200mm;

[0043] (2) Hot rolling process: hot-rolled coils are obtained after the billet is heated, dephosphorized, hot-rolled and laminar cooling, wherein the heating temperature is 1250°C, the finishing rolling temperature is 1070°C, and the final rolling temperature is 860-900°C , the coiling temperature is 580-620°C, and the thickness of the hot-rolled sheet is 3.75mm;

[0044] (3) pickling process: the above-mentioned hot-rolled coils are cold-rolled into cold-rolled strip steel 2.3mm after pickling, wherein the cold-rolling reduction rate is 40%;

[0045] (4) Hot-dip galvanizing and annealing process: After the above-mentioned cold-roll...

Embodiment 2

[0048] The high-formability and high-strength hot-dip galvanized dual-phase steel of this embodiment is produced according to the following process:

[0049] (1) Smelting process: C: 0.13%, Si: 0.32%, Mn: 1.95%, Mo: 0.28%, Als: 0.047%, Nb: 0.043%, P: 0.020%, S: 0.005%, N: 0.004% , Ti: 0.053%, and control the V content in the converter, by controlling the V content in the original molten iron instead of adding vanadium-iron alloy, and then casting it into a slab with a thickness of 200mm;

[0050] (2) Hot rolling process: hot-rolled coils are obtained after the billet is heated, dephosphorized, hot-rolled and laminar cooling, wherein the heating temperature is 1250°C, the finish rolling temperature is 1080°C, and the final rolling temperature is 890-930°C , the coiling temperature is 610~640℃, and the hot rolling thickness is 3.75mm;

[0051] (3) Pickling process: the above-mentioned hot-rolled coils are cold-rolled into cold-rolled thin strips of 2.3mm after pickling, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com