Basement floor post-cast strip structure and construction method thereof

A technology of basement floor and post-pouring belt, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as damage to the bottom plate, affecting construction quality, and failure of the waterproof layer of the post-casting belt, so as to reduce costs and prevent Damage failure, good effect of structural waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with the accompanying drawings, the present invention will be further described in detail.

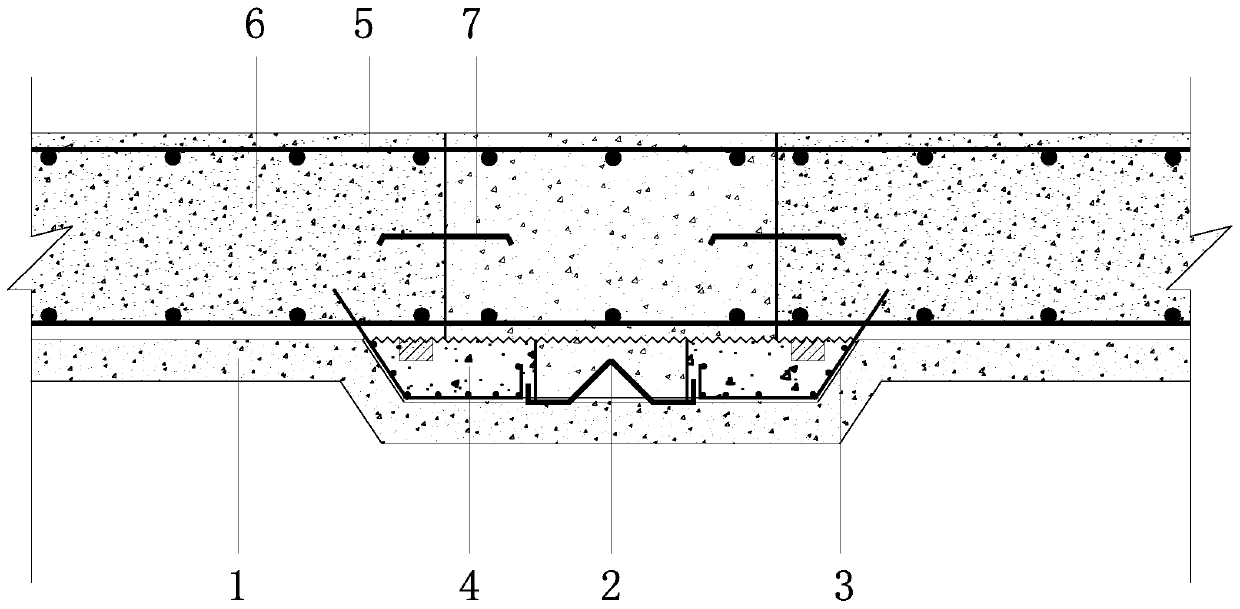

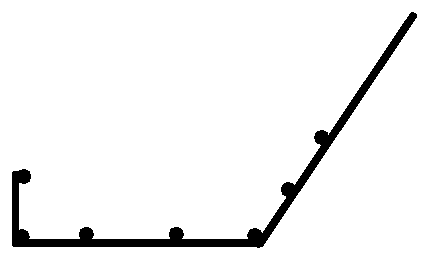

[0024] As shown in the figure, a basement floor post-cast belt structure includes a cushion layer 1, a V-shaped water-stop steel plate 2, a post-cast steel bar 3, a post-cast belt 4, a bottom plate steel mesh 5, a bottom plate 6, and a water stop lag 7 ; The cushion layer 1 is a plain concrete cushion structure, and the middle part of the cushion layer 1 is provided with a section of inverted trapezoidal depression, and the center of the depression is fixed with a V-shaped water-stop steel plate 2 by screws; the V-shaped water-stop steel plate 2 is V-shaped full-length steel plate with wing plates at both ends, and a welding section with one end upturned on both sides of the wing plate. The opening of the V-shaped water-stop steel plate 2 faces the direction of the cushion layer 1; A post-cast steel bar 3 is welded on the top, and the post-cast steel bar 3 is atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com