Furnace door of thermal forming furnace

A thermoforming and furnace door technology, which is applied in the direction of forming tools, furnaces, furnace components, etc., can solve problems such as increased maintenance costs and repair time, cracking of ceramic roller ceramic plates, and affecting normal use of equipment, so as to shorten maintenance time, Reduce heat radiation, overcome the effect of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

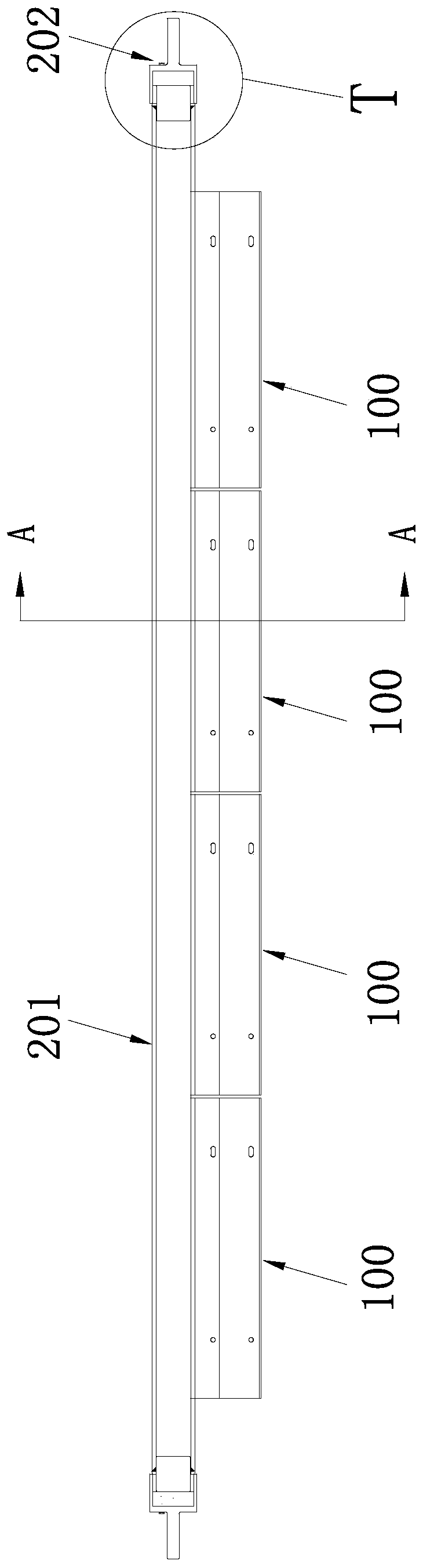

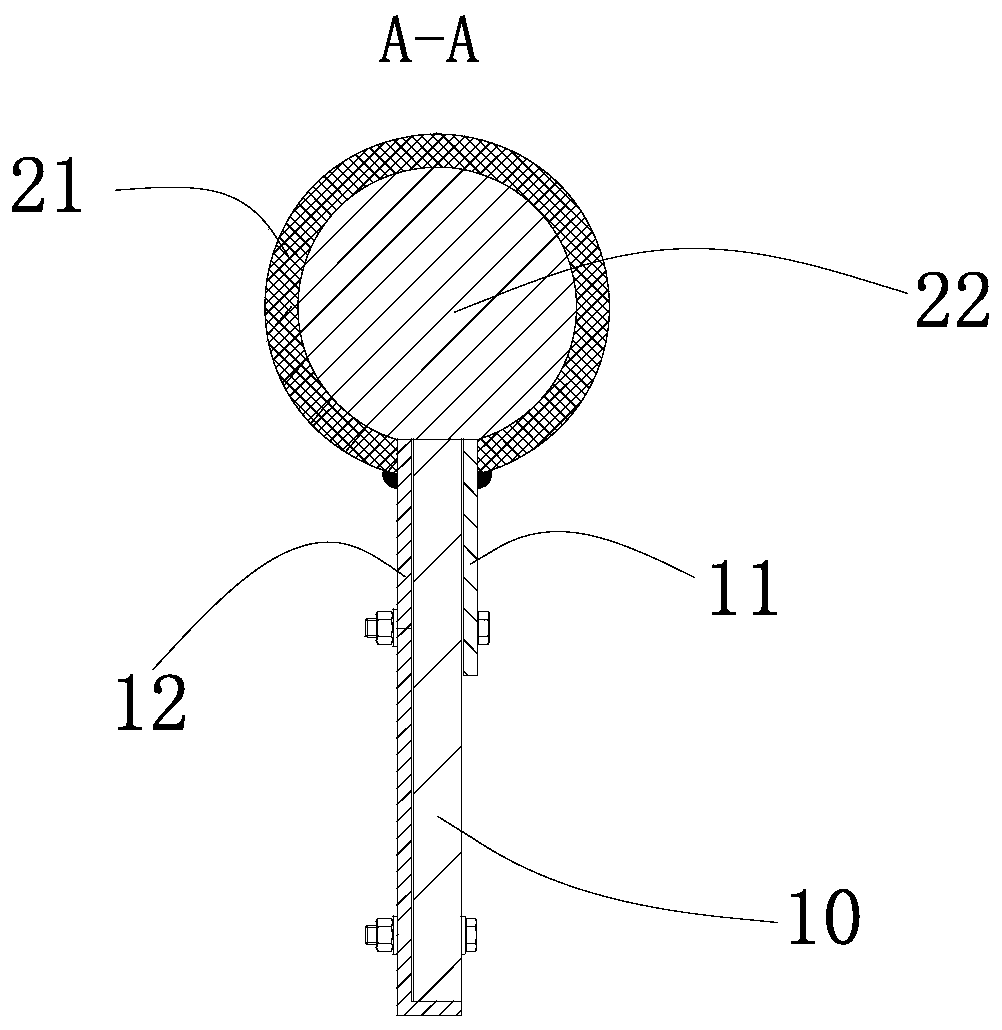

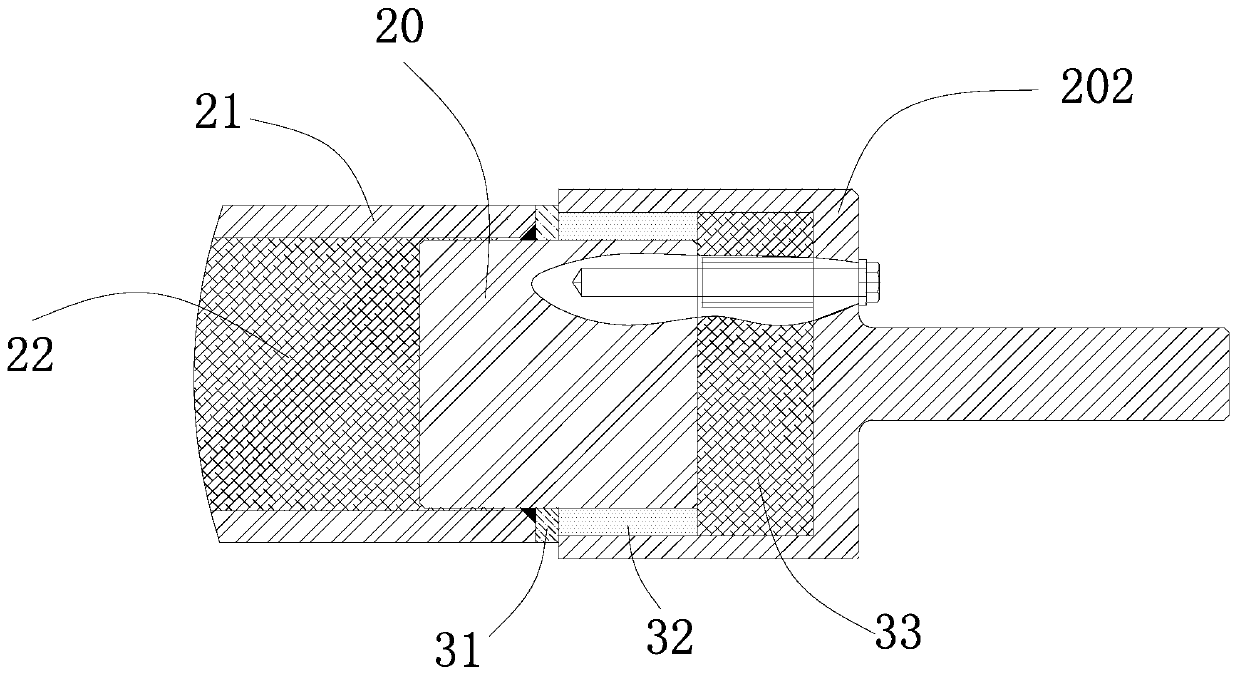

[0025] Such as figure 1 , figure 2 and image 3 As shown, a furnace door of a thermoforming furnace is rotatably connected to the bearing seats on both sides of the thermoforming furnace body. The furnace door includes a door body 100 for closing the furnace body inlet or outlet, and a door body 100 A fixedly connected rotating body, the rotating body includes a rotating shaft 201 fixedly connected to the door body 100, a detachably connected shaft head 202 at both ends of the rotating shaft 201, and the shaft heads 202 at both ends are respectively installed in rotation with the bearing seats on both sides, The shaft head 202 is made of heat-resistant steel, and a heat insulation mechanism is provided between the rotating shaft 201 and the shaft head 202 .

[0026] Specifically, the shaft head 202 is formed with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap