Automatic calibration method for water level indicator of high-head lock

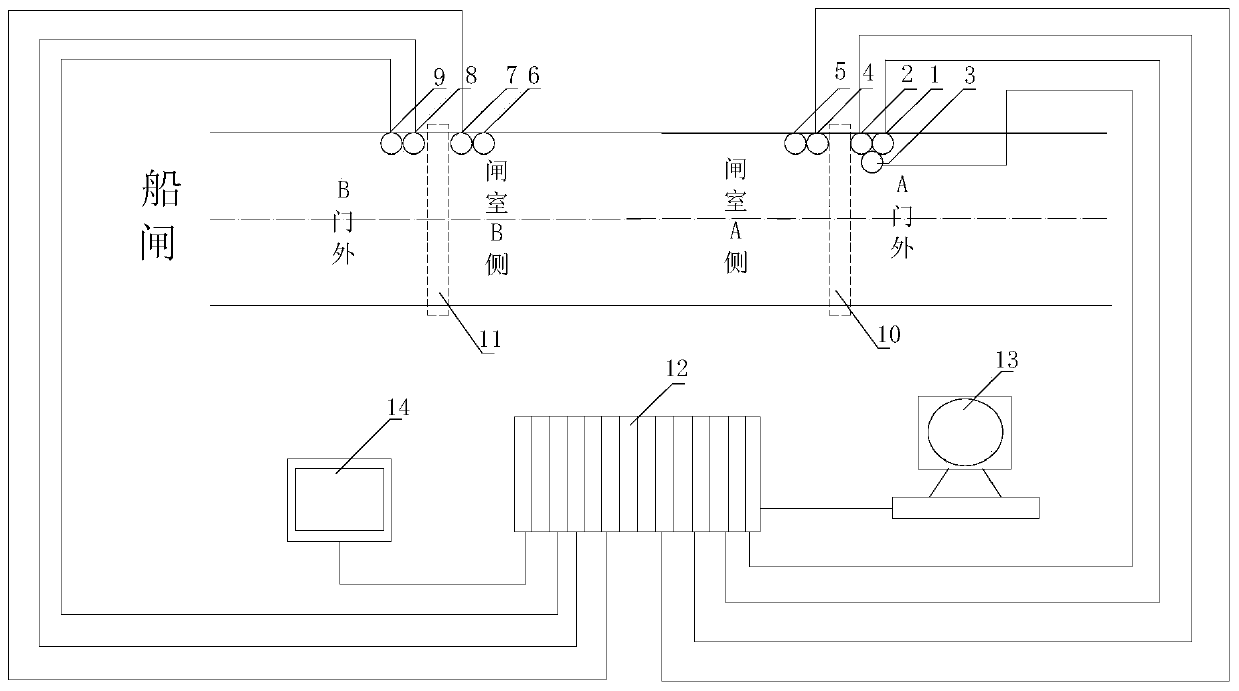

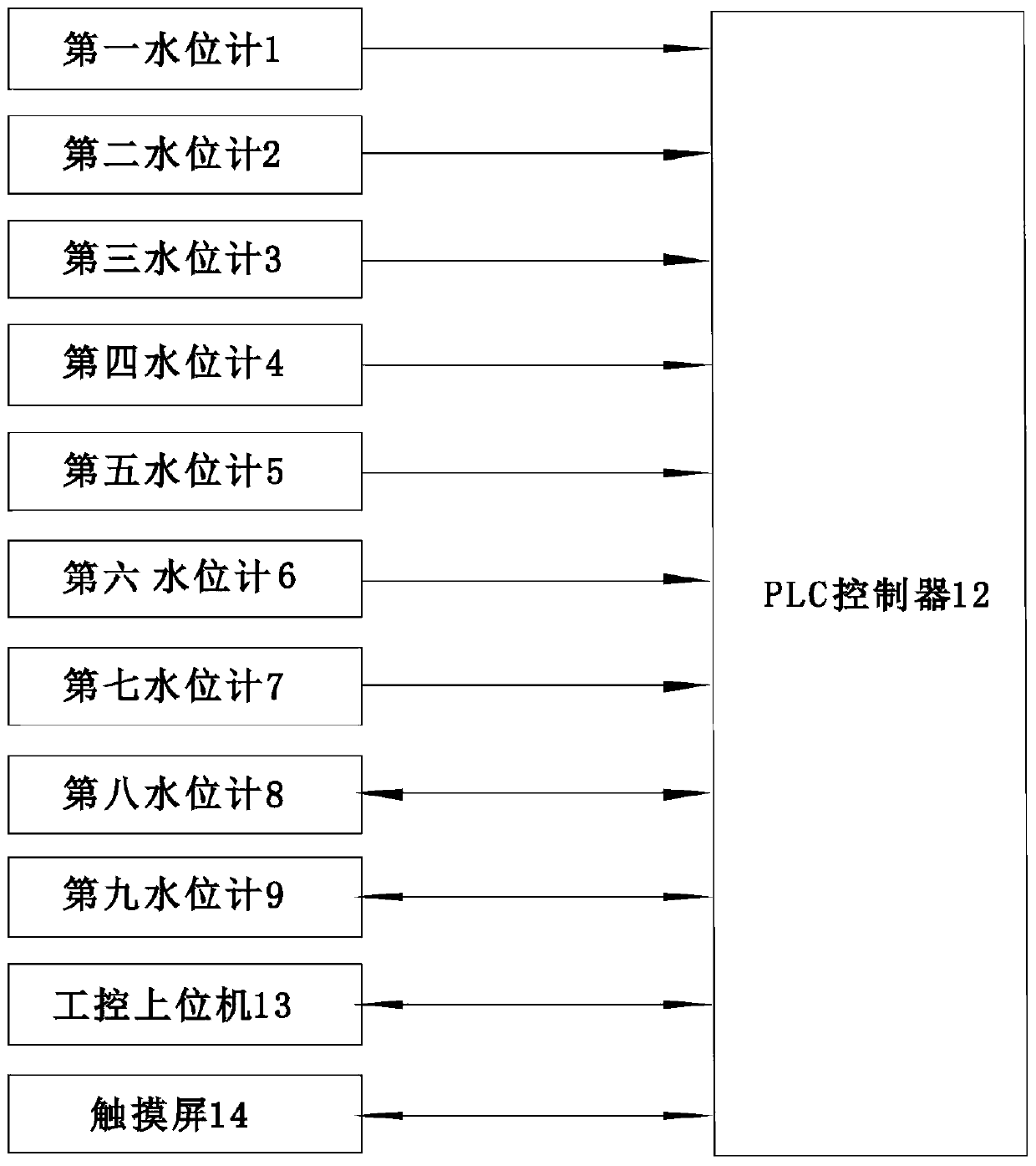

An automatic calibration and water level gauge technology, which is applied to ship locks, testing/calibration devices, and ship lifting devices, can solve problems such as distortion of water level gauge readings, affecting the normal operation of ship locks, and zero drift of water level gauges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

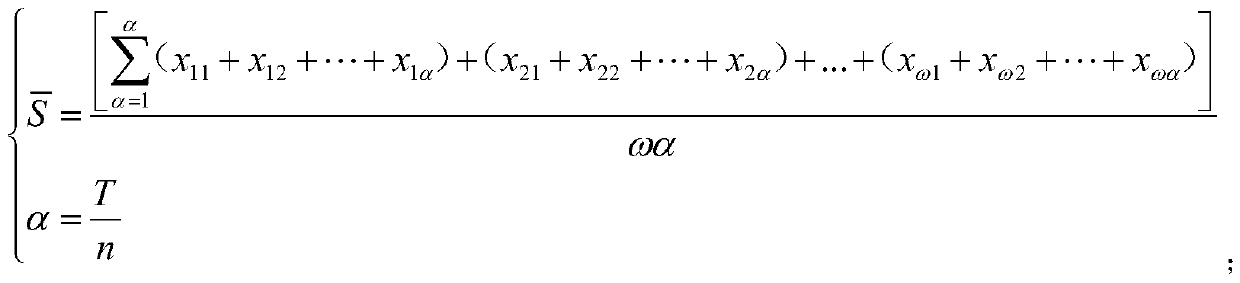

[0070] (1): The mathematical model of the average value of the water level interval:

[0071] The formula for the mean value of the water level interval is as follows:

[0072]

[0073] in: —The average value of the water level interval; x—the instantaneous value of the water level gauge; ω—the number of water level gauges at the water level point; T—the water level collection interval; n—the instantaneous value collection frequency.

[0074] x 11 、x 12 … x 1α - the first, second...α instantaneous values sequentially collected by the first water level gauge 1 at the collection frequency n;

[0075] x 21 、x 22 … x 2α - the first, second...α instantaneous values sequentially collected by the second water level gauge 2 at the collection frequency n;

[0076] x ω1 、x ω2 … x ωα —The 1st, 2nd...α instantaneous values sequentially collected by the ωth water level gauge at the collection frequency n;

[0077] x, ω, and n are all known numbers, and T can be obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com