System and method for scanning and detecting tiny scratch defects of panel

A technology for scratch defect and scanning detection, which is applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, and can solve the problems of subtle scratches and background confusion, small mirror reflection angles, and indistinguishability, etc. Achieve fast dynamic surface detection, do not affect the production speed, and achieve the effect of fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The invention provides a scanning detection system and method for fine scratch defects on a panel.

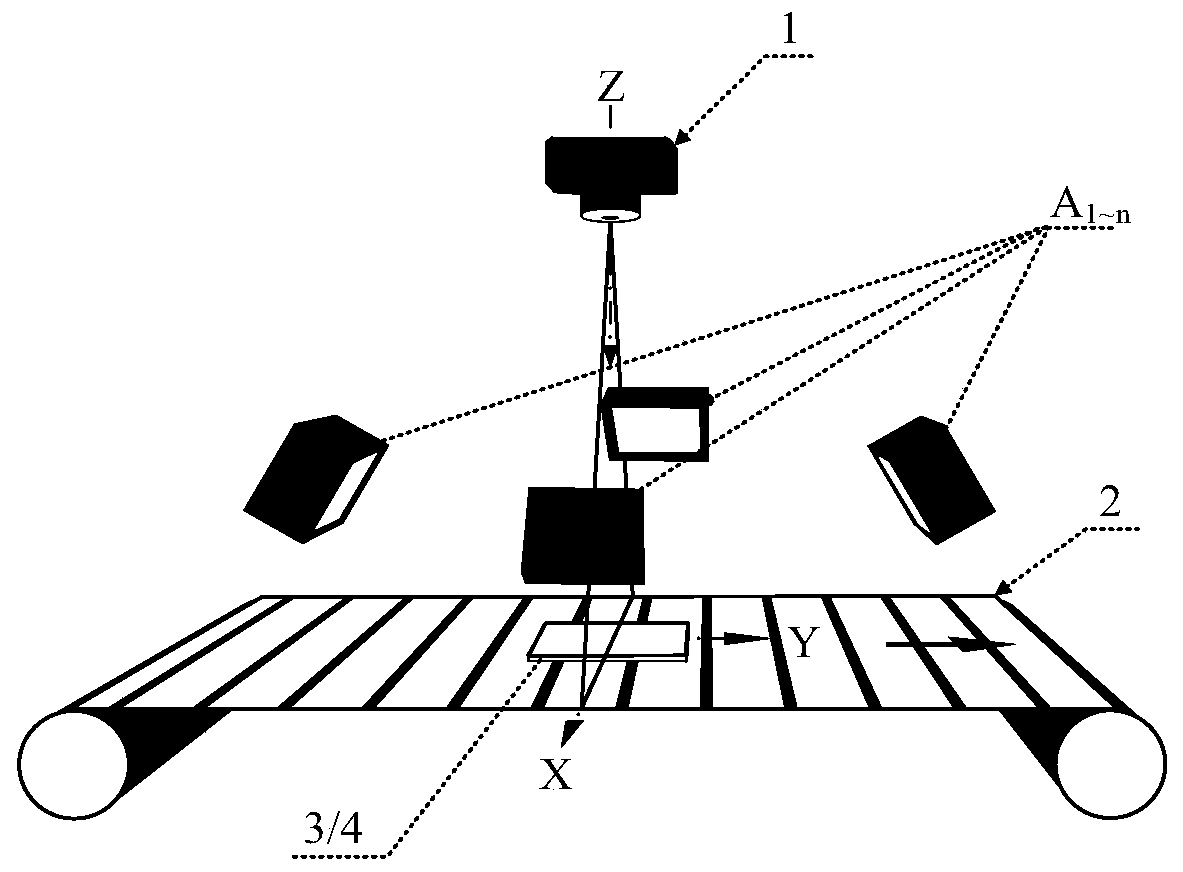

[0032] Such as figure 1 As shown, the system includes a multi-spectral line scan camera 1, a light source array A i and the transmission mechanism 2, the multispectral line scan camera 1 is located above the transmission mechanism 2, and the scanning line of the multispectral line scan camera 1 is perpendicular to the movement direction of the transmission mechanism 2, and the light source array A i It is located between the multi-spectral line scan camera 1 and the transmission mechanism 2, on which the panel 3 to be tested is placed.

[0033] In practical application, the panel under test is placed on the transmission mechanism; the multi-spect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com