Explosion-proof structure of cylindrical battery

A cylindrical battery, explosion-proof structure technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as internal pressure rise, and achieve the effect of preventing explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

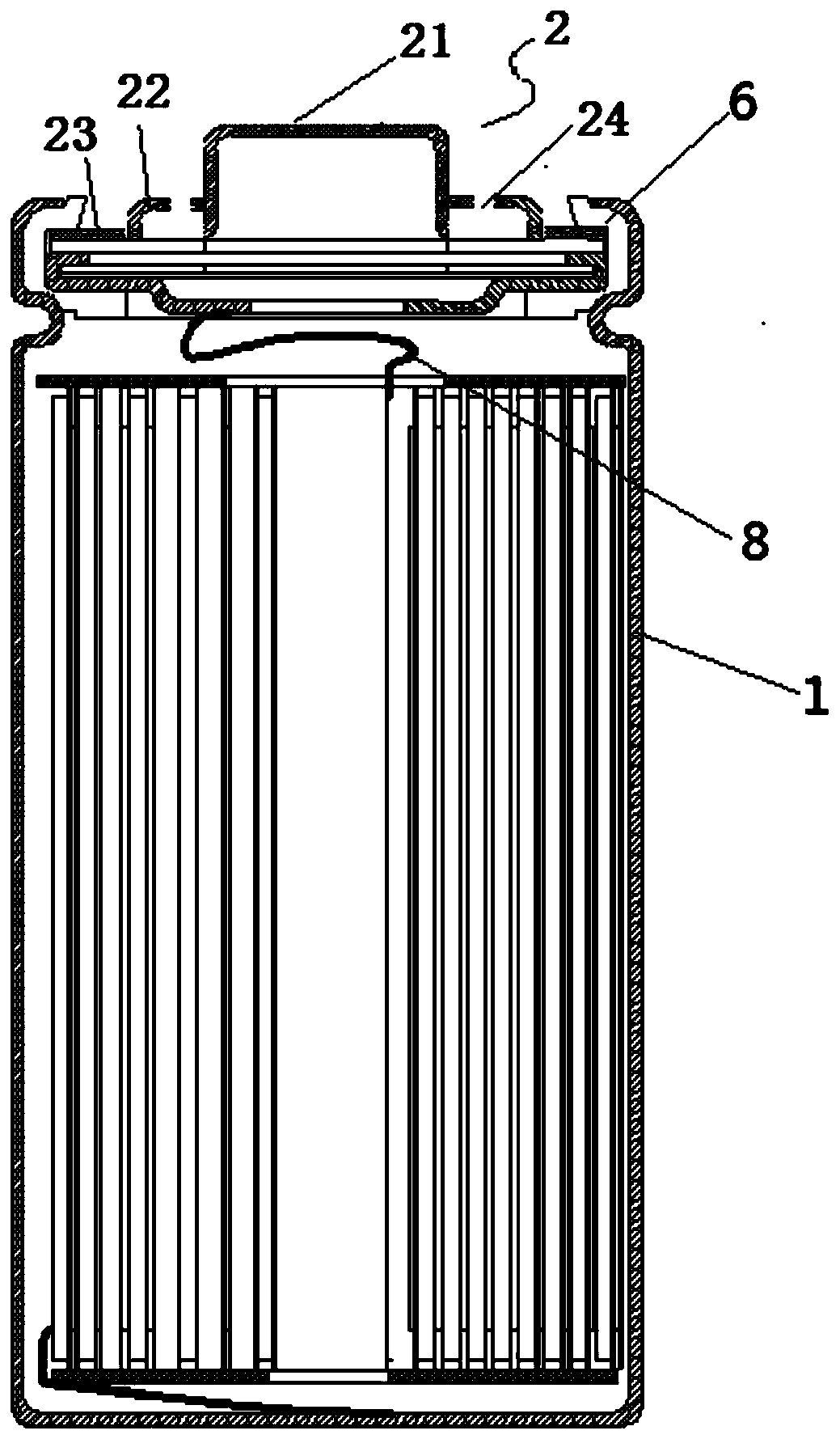

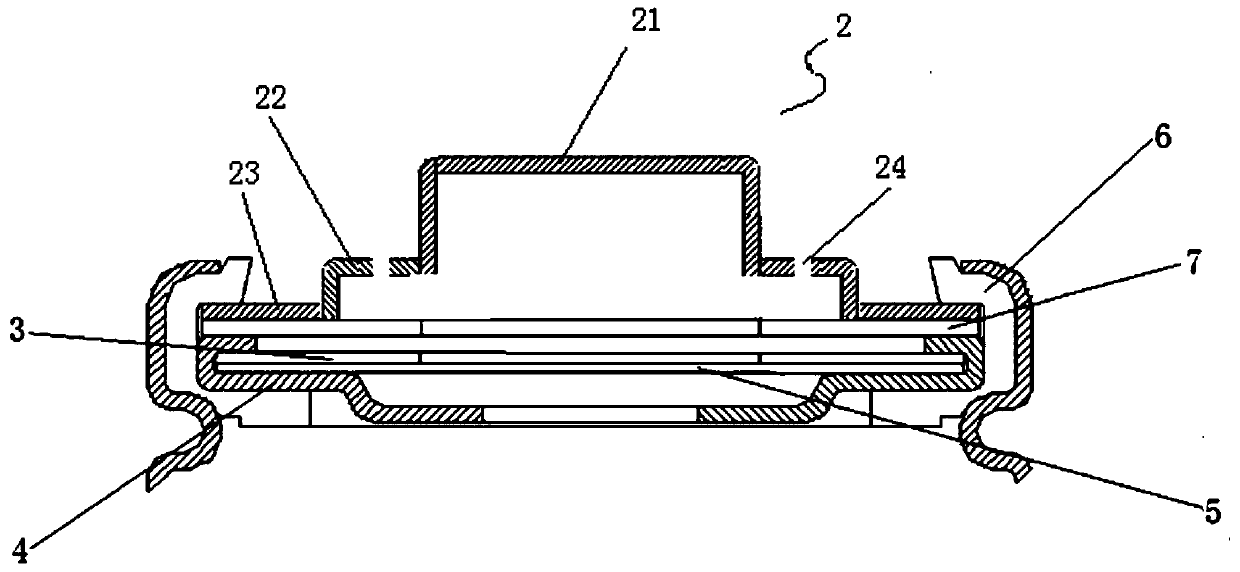

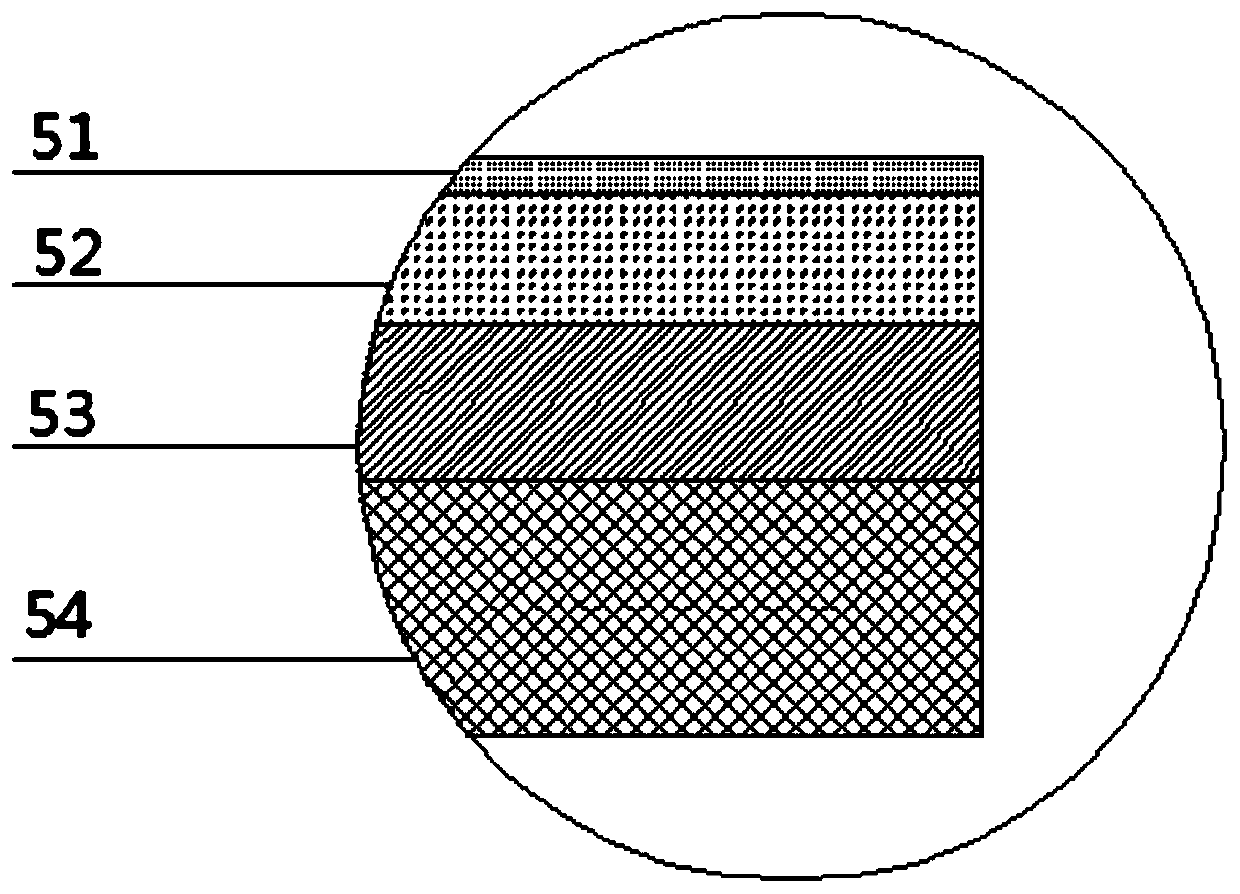

[0012] refer to Figure 1-3 1. A novel explosion-proof structure of a cylindrical battery, comprising a convex explosion-proof cap and a battery core casing 1, the convex explosion-proof cap including an upper cover 2 and a lower cover, and the upper end of the battery core casing buckles the upper cover toward the inner edge Edge; the lower cover includes a stainless iron sheet 3 and a bottom cover 4 connected to the positive lead end, the upper edge of the bottom cover buckles the edge of the stainless iron sheet to the inner ring edge, and the upper cover 2 is formed by a concentric shaft The upper boss 21, the middle ring step edge 22, and the lower ring step edge 23 are formed, and the exhaust holes 24 are uniformly distributed on the middle ring step edge; an explosion-proof membrane 5 is arranged between the bottom cover and the stainless iron sheet , the explo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com