Net rack rod part machining method

A processing method and grid rod technology are applied in metal processing equipment, manufacturing tools, used abrasive processing devices, etc., which can solve the problems of low utilization rate of steel balls, high scrapping rate of steel balls, and slow shot blasting speed, etc., to achieve Improve the utilization rate of steel balls, reduce the fixing time, and avoid the effect of mutual collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for processing grid rods, comprising the following steps:

[0030] a. Steel pipe blanking: the raw steel pipe is cut to the required length by the plasma grid automatic cutting machine, and the blanking groove is formed at one time;

[0031] b. Steel pipe shot blasting derusting: derusting the steel pipe through shot blasting device;

[0032] c. Welding of grid rods: Weld the two cone heads to the two ends of the steel pipe respectively through the automatic welding mechanism;

[0033] d. Paint coating of grid rods: the paint of grid rods is mainly sprayed, and the thickness of the coating is controlled by a dry and wet film thickness gauge;

[0034] e. Marking of rods: the surface of the rods is stamped and marked

[0035] f. Packing and shipping: the rods are bundled by packing;

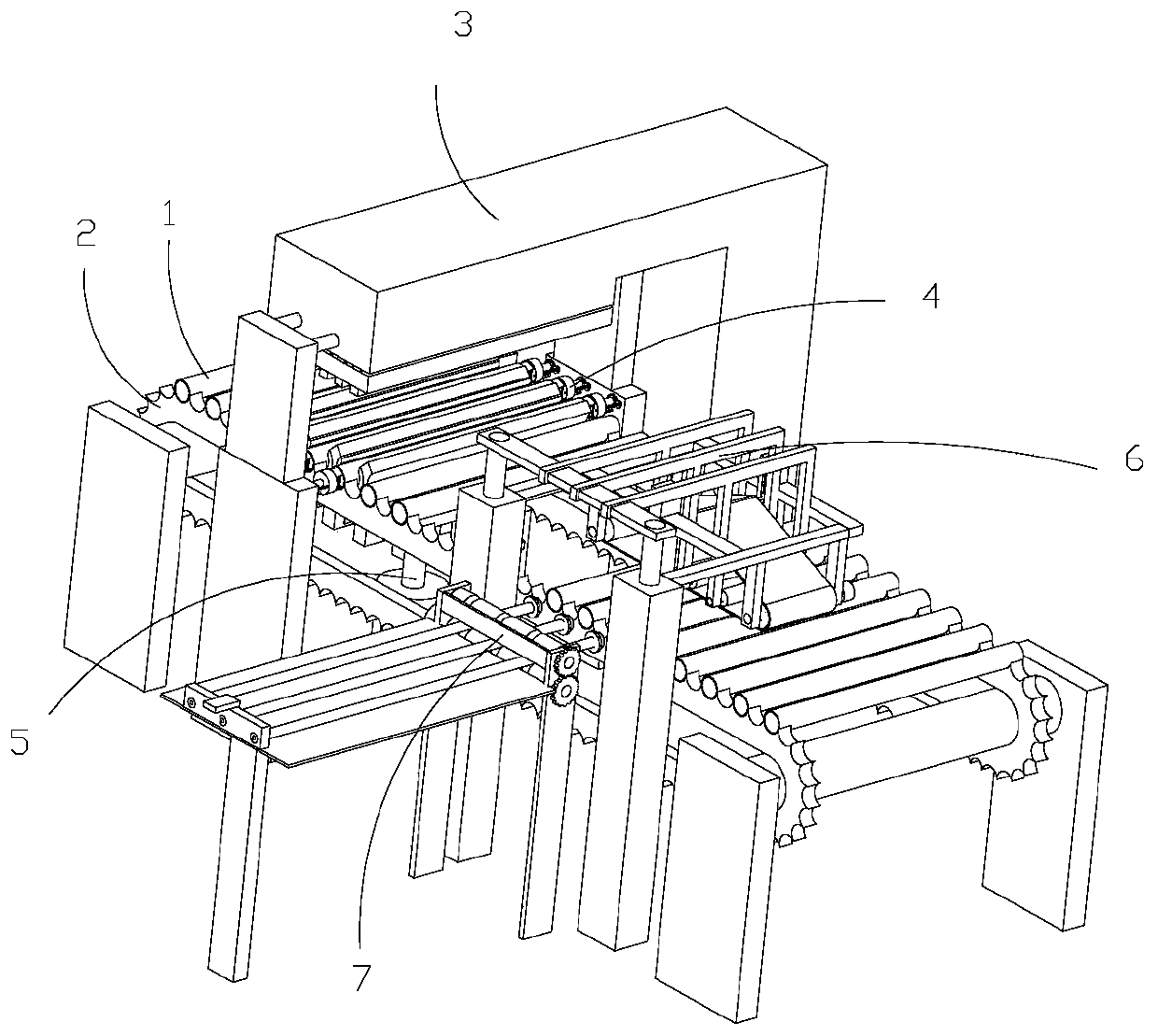

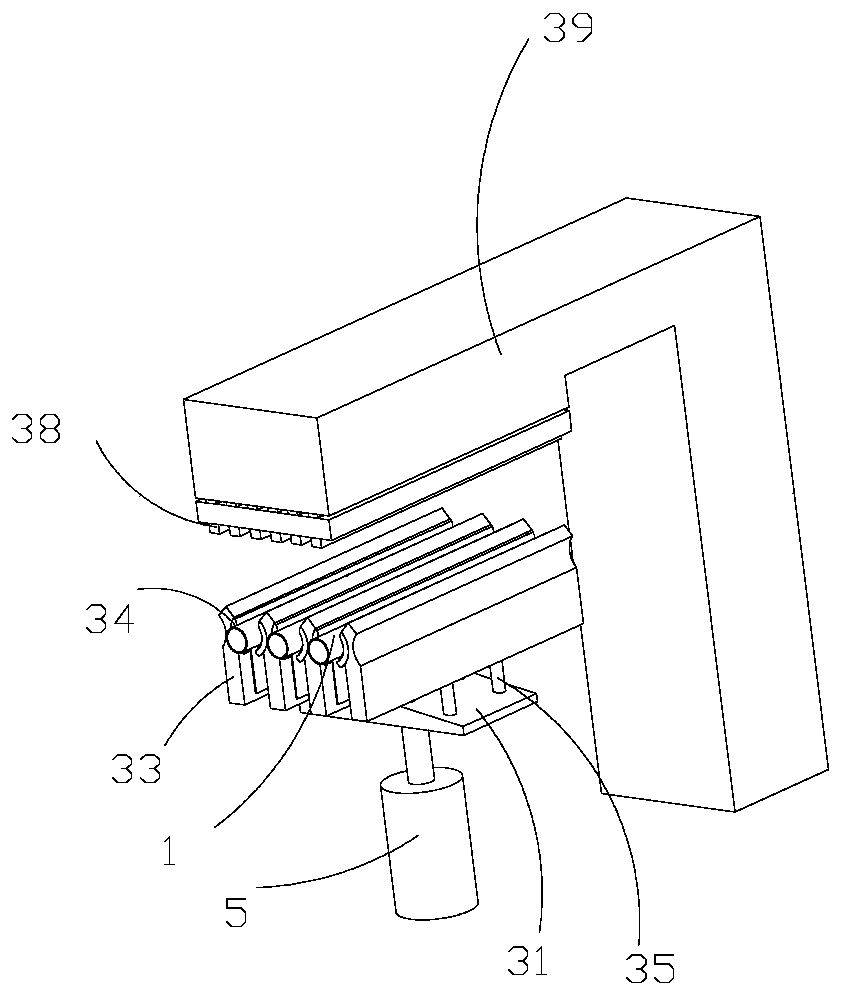

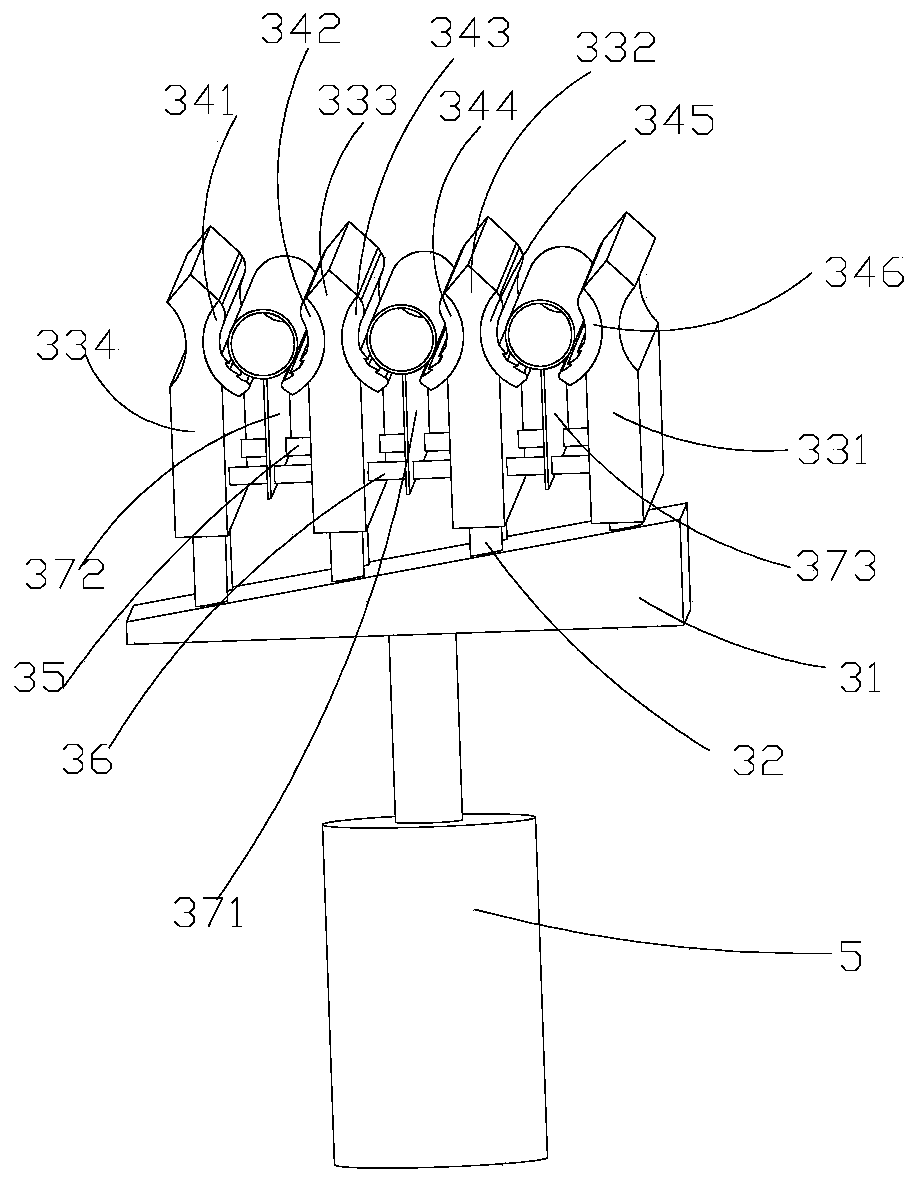

[0036] Such as Figure 1-9The steel pipe shot peening device described in step b includes the steel pipe 1 to be processed, the steel pipe steel pipe delivery assembly 2, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com