Two-phase flow municipal sludge treatment device

A technology of urban sludge and treatment device, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Exchange and other issues to achieve the effect of prolonging the time, not easy to accumulate, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

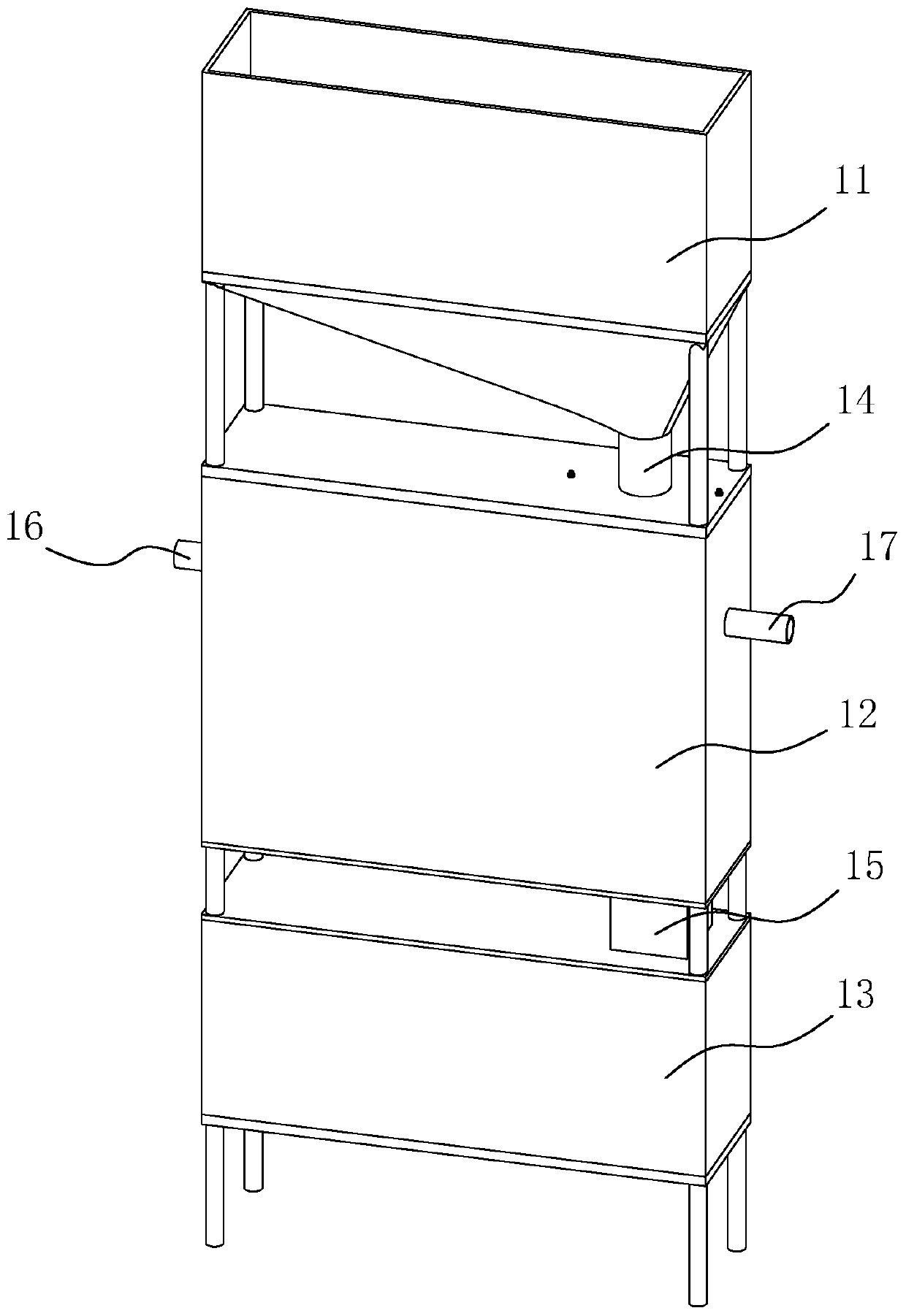

[0044] A two-phase flow municipal sludge treatment device, referring to figure 1 , which includes a wet mud bin 11, a drying bin 12 and a dry mud bin 13 connected in sequence. The wet mud bin 11 communicates with the drying bin 12 through the feed pipe 14 , and the drying bin 12 communicates with the dry mud bin 13 through the discharge pipe 15 . The sidewalls at both ends of the drying chamber 12 are respectively pierced and welded with a flue gas inlet 16 and a flue gas outlet 17 .

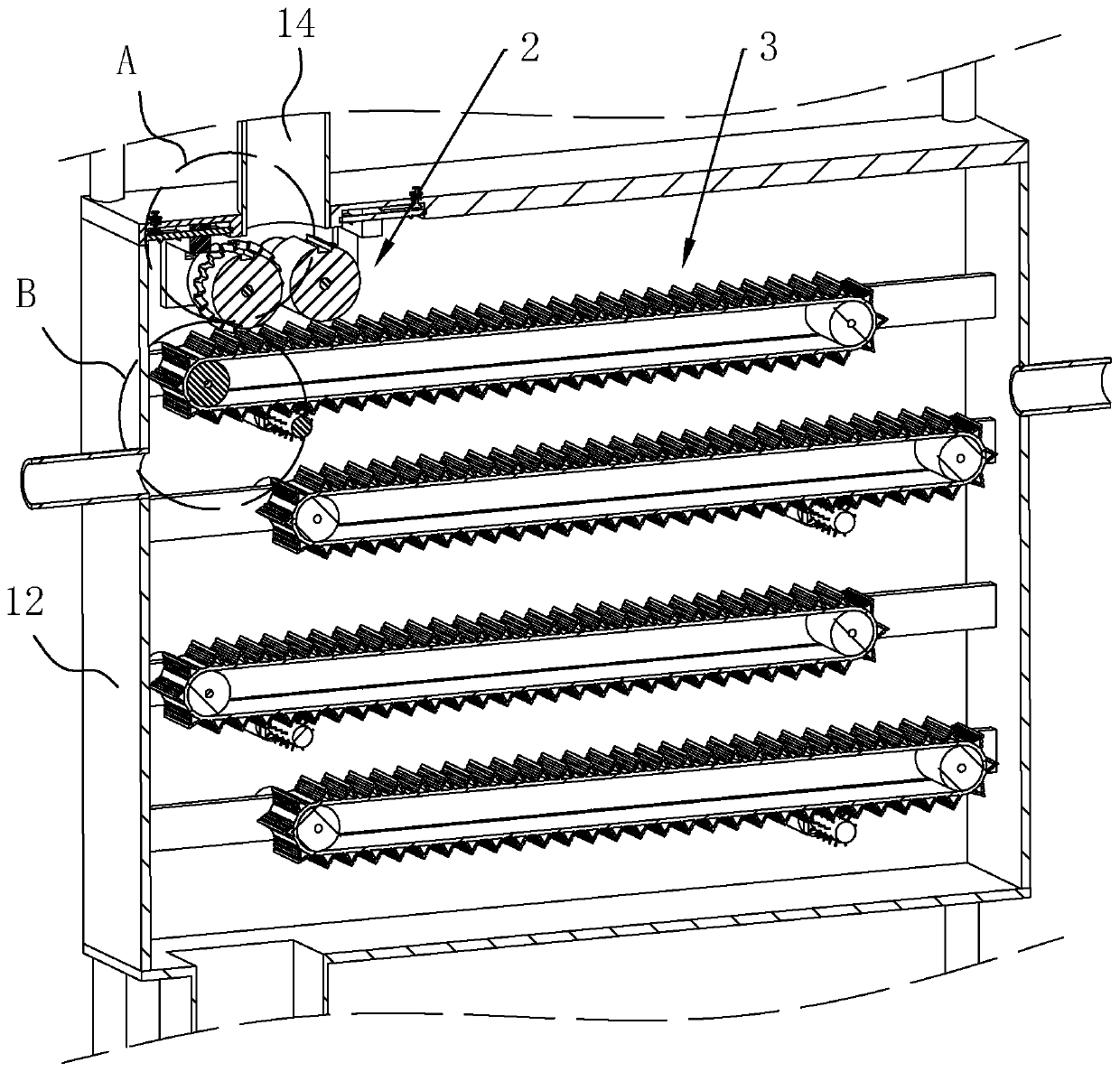

[0045] refer to figure 2 , The drying bin 12 is located below the feed pipe 14 and is provided with an extruding device 2 , and the drying bin 12 is located below the extruding device 2 and is provided with a feeding device 3 .

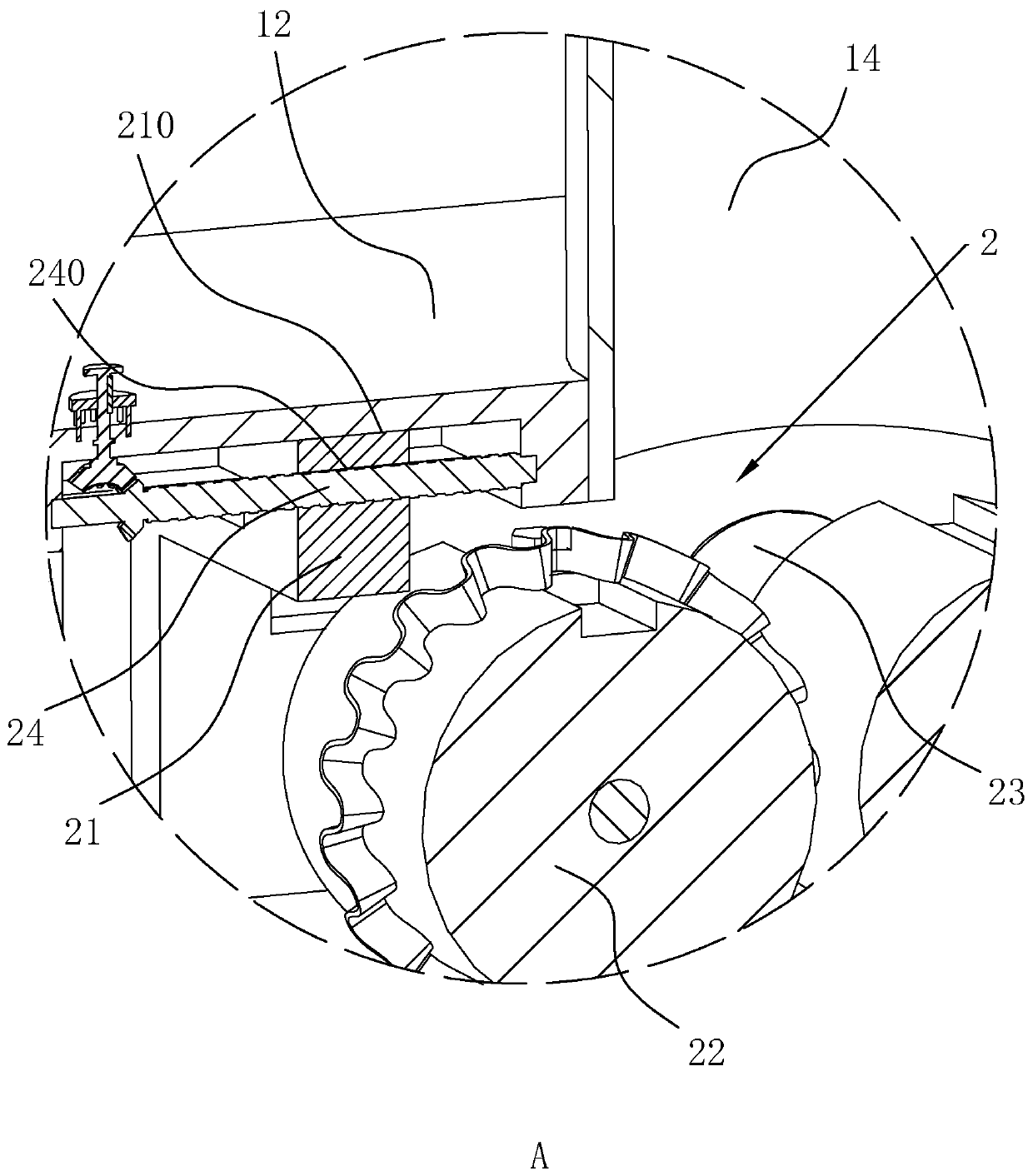

[0046] refer to image 3 The inner top wall of the drying bin 12 is located on both sides of the feed pipe 14 and is symmetrically provided with chute 210 , and the sliding connection in the chute 210 is fitted with a slider 21 , and the cross section of the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com