Preparation process of volute spiral spring

A scroll spring and preparation technology, which is applied in the field of spring processing, can solve the problems of low fatigue strength, low tissue precision of scroll spring, and low product quality, and achieve the effect of increasing tissue density, improving quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

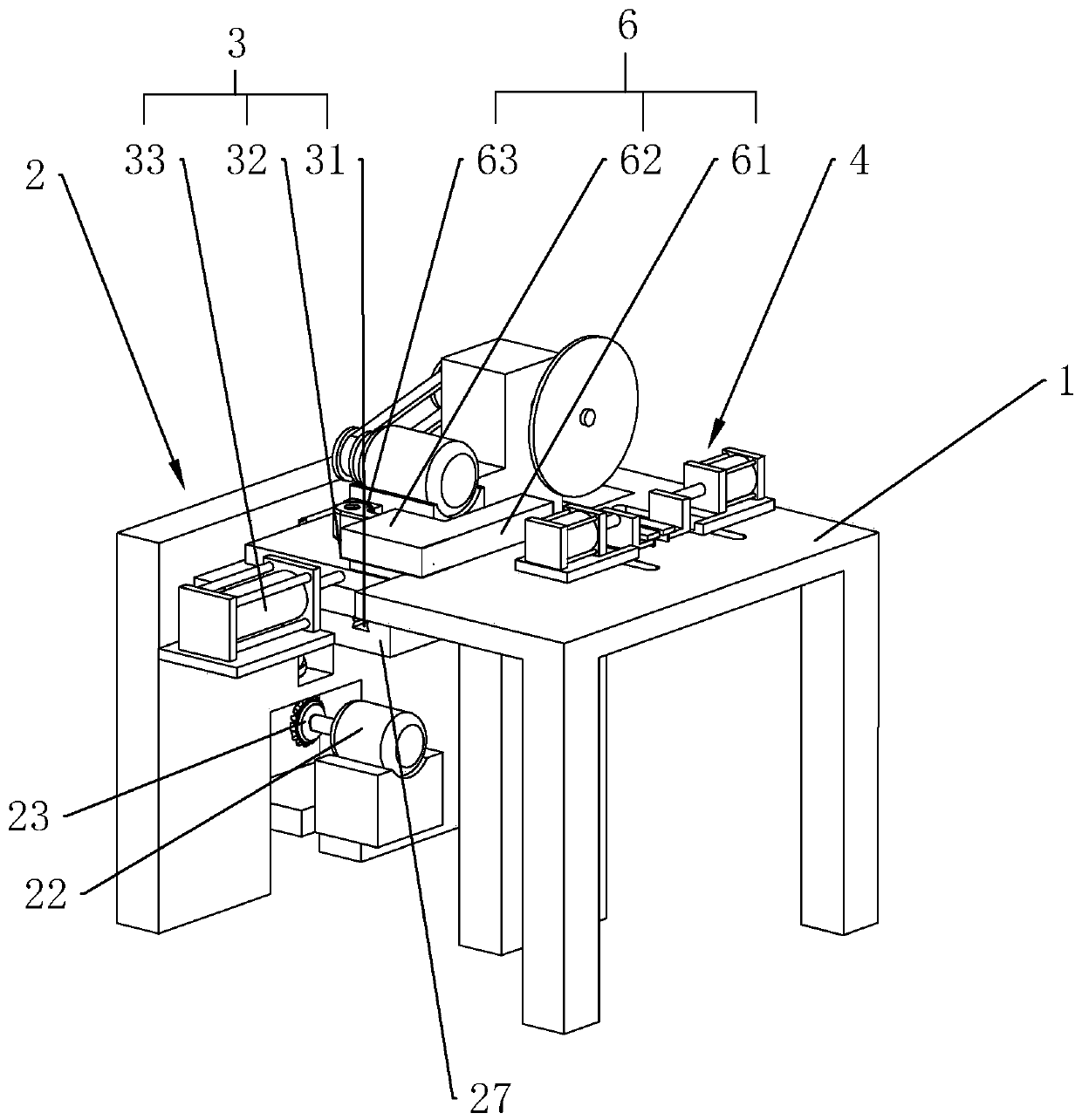

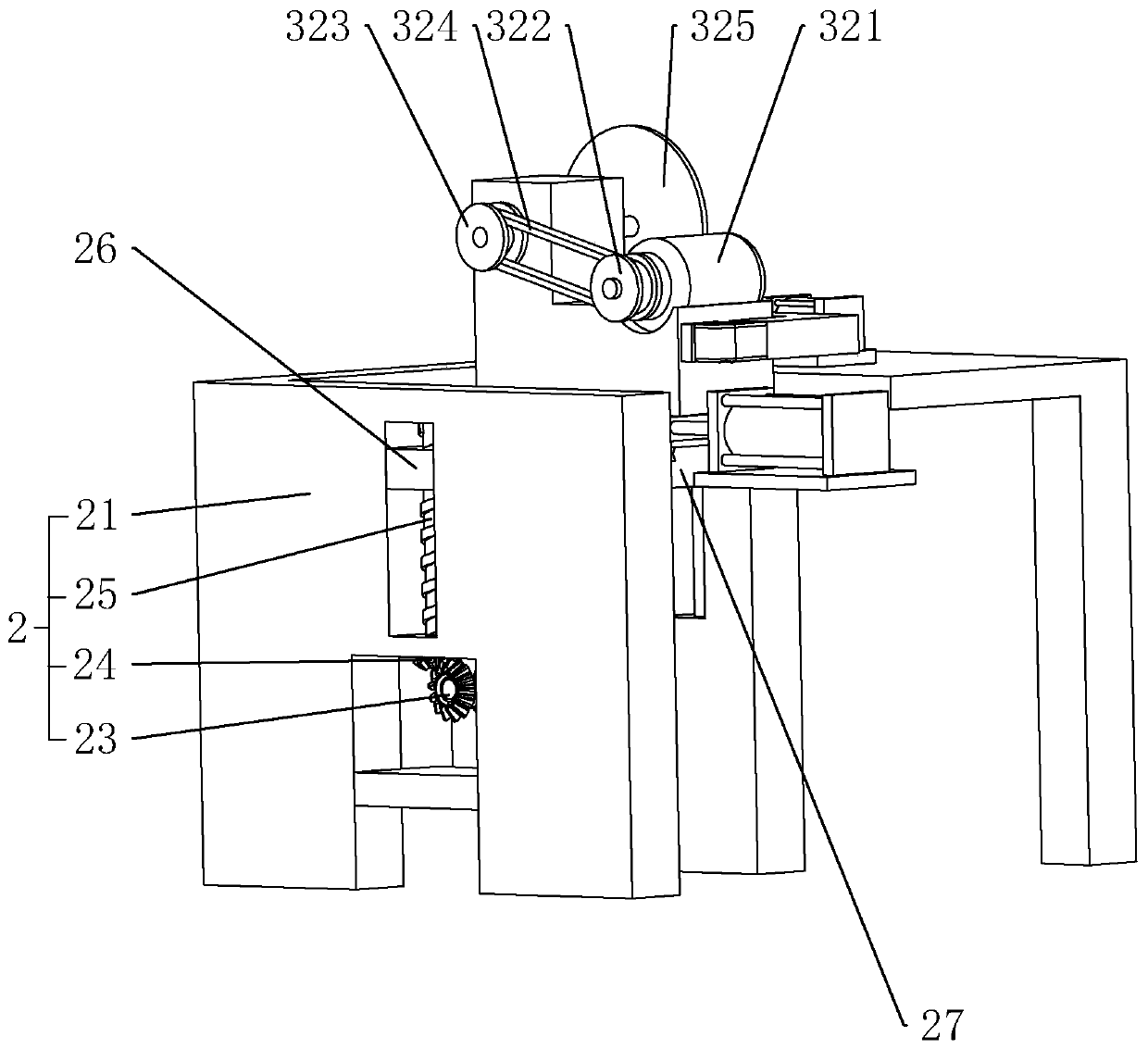

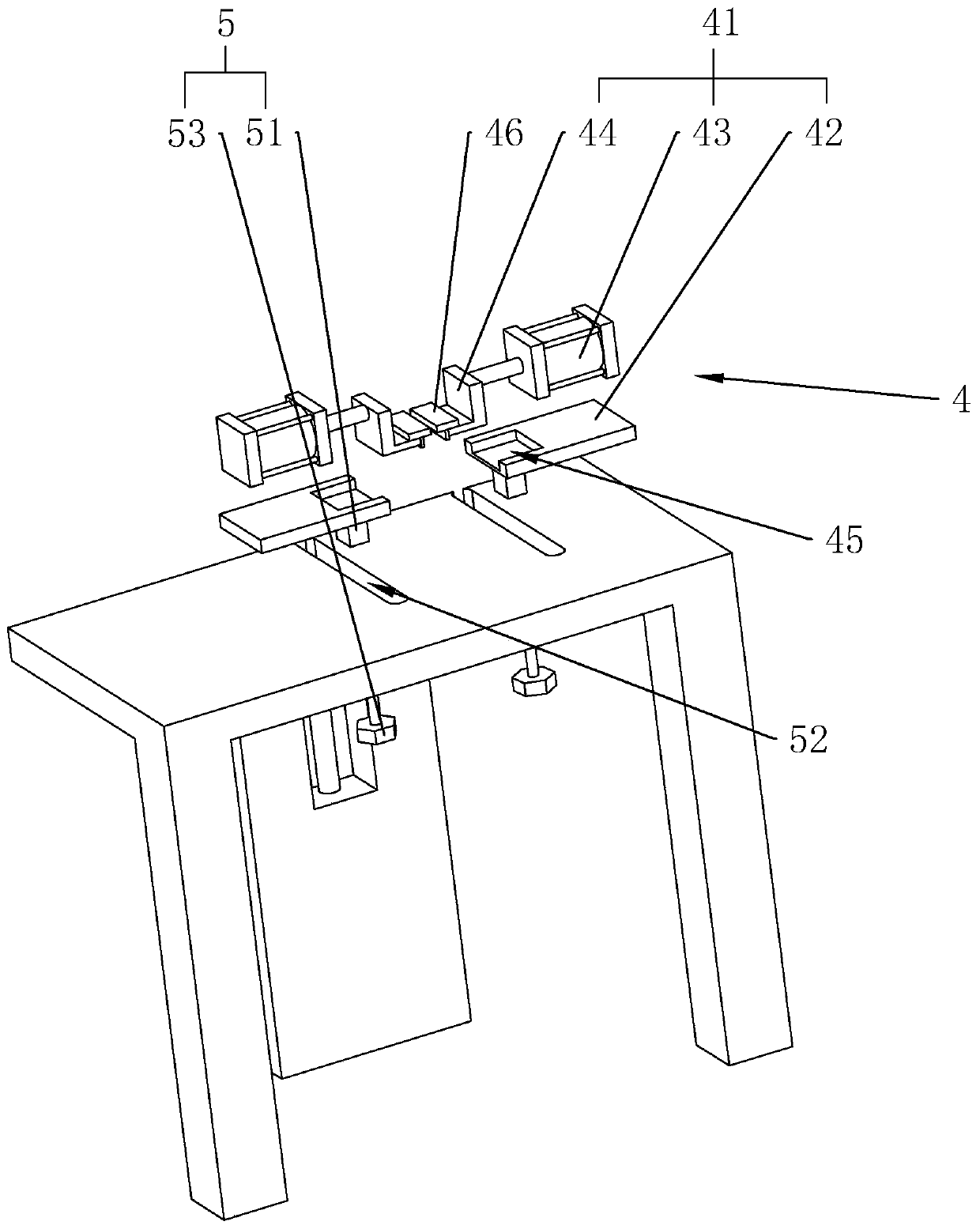

[0047] refer to figure 1 , the preparation technology of a kind of scroll spring disclosed by the present invention, comprises the following steps:

[0048] S1: spring raw material preparation;

[0049] S2: Punching the raw material to obtain the punching material;

[0050] S3: forming the punching material to obtain the forming material;

[0051] S4: First use the spring end grinding equipment to grind the end of the molding material and deburr the inside and outside, and then use the special mandrel for winding processing. During the winding processing, the bottom of the molding material is paved with corrugated cardboard, and the winding is completed. Finally, the coil spring intermediate material is obtained;

[0052] S5: Carry out normalizing, quenching, and tempering treatments to the coil spring intermediate material in turn to obtain a coil spring semi-finished product; wherein, the holding time of the coil spring intermediate material for normalizing treatment is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com