Construction method of a large prefabricated pipe gallery

A construction method and pipe gallery technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problem of inability to hoist, construct and install large-scale prefabricated pipe corridors, and achieve a simple and fast translation method, small installation error, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

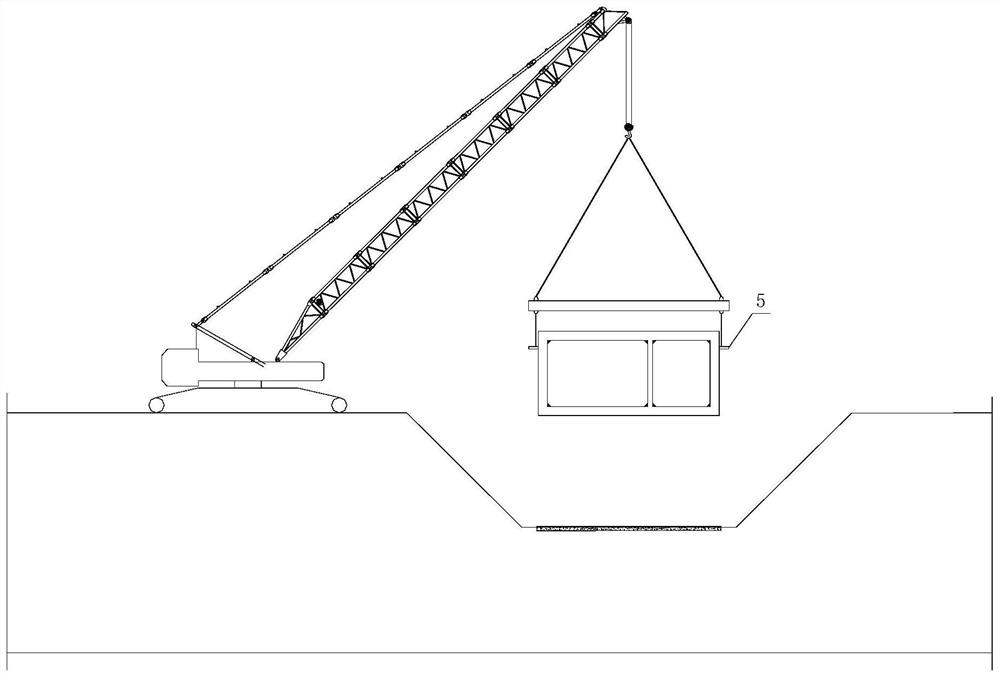

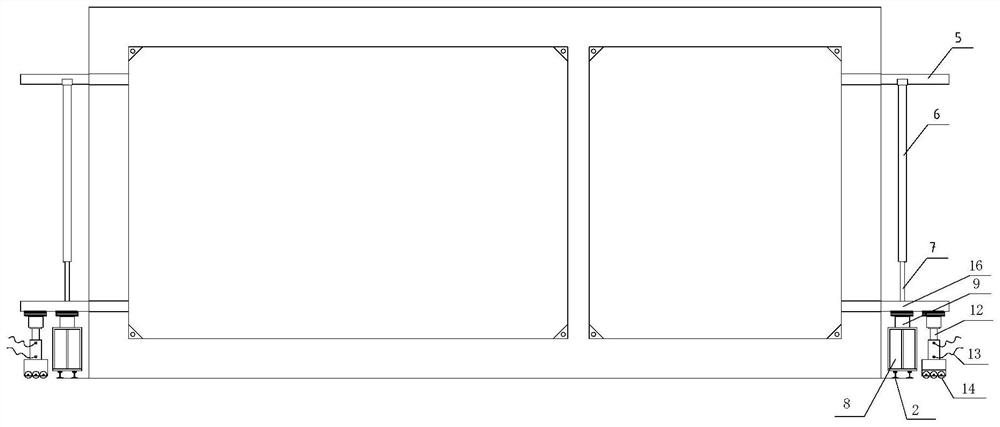

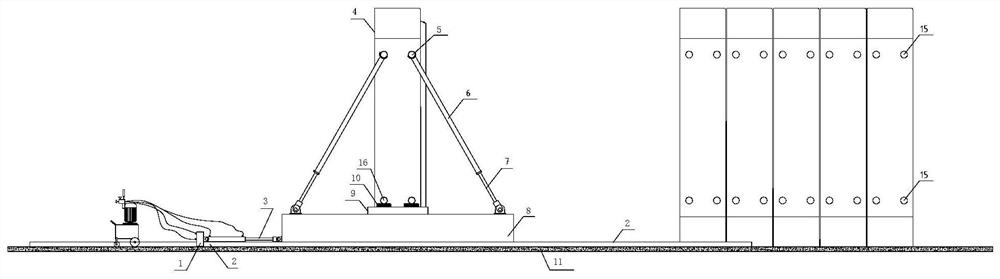

[0026] See Figure 1-Figure 6 , a construction method of a large-scale prefabricated pipe gallery, the method is to lay a track 2 in the foundation pit, and transport the large-scale prefabricated pipe gallery 4 to the installation position by translation, so as to realize the installation of the large-scale prefabricated pipe gallery 4, the specific method is as follows:

[0027] 1) Make the push trolley: the push trolley includes a steel beam frame 8, a supporting steel pipe 6, and an adjusting screw 7. The adjusting screw 7 is hinged on the upper end of the steel beam frame 8, and the supporting steel pipe 6 is threadedly connected to the adjusting screw 7. The upper end of the steel pipe 6 is provided with a bracket, and the bracket matches the hoisting steel pipe 5 on the large prefabricated pipe gallery 4 .

[0028] The length of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com