A Rotary Kiln Air Guide Cover Structure

A technology of air guide hood and rotary kiln, which is applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of easy de-welding deformation at the welding place, shortened life of refractory material, and inability to locate the air guide hood 1, so as to ensure long-term Stable and forward running, stable and reliable operation, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

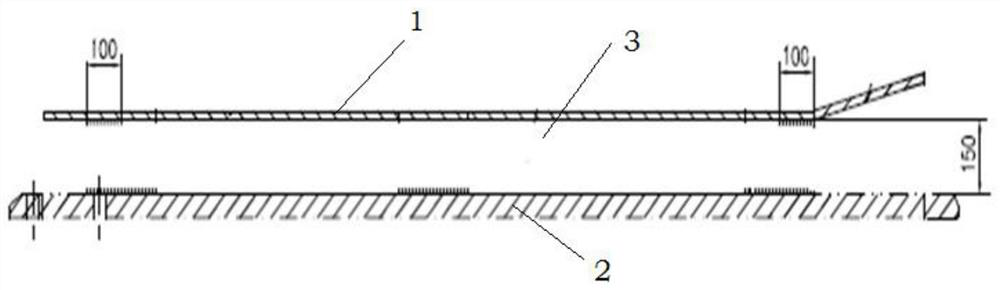

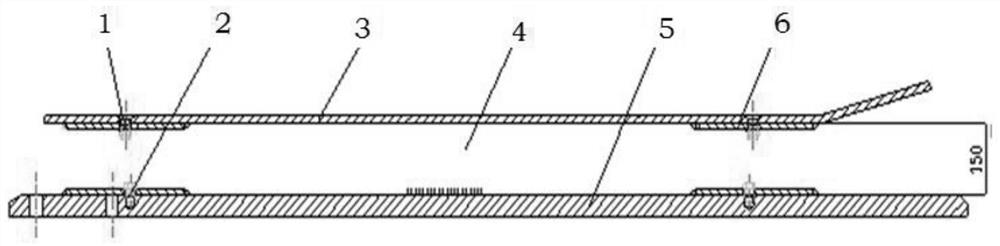

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] like figure 2 As shown, a rotary kiln air guide structure includes an air guide 3, a rib plate 4 and a cylinder body 5, the rib plate 4 is located between the air guide cover 3 and the cylinder body 5, the air guide cover 3 and the rib The plate 4 is welded, the rib plate 4 is welded with the cylinder body 5, and the cylinder body 5 is installed on the rotary kiln. Two sets of U-shaped connecting plates 6 are respectively provided on both sides of the rib plate 4, and the two sets of connecting plates 6 is placed between the wind deflector 3 and the rib plate 4, and the other two sets of connecting plates 6 are placed between the rib plate 4 and the cylinder body 5, and the U-shaped opening of the connecting plate 6 is connected to the rib plate 4, so that The connecting plate 6, the air guide cover 3 and the rib plate 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com