Method for laying cable troughs in roadbed

A technology of cable trough and subgrade, which is applied in the direction of cable installation, cable installation device, and cable installation in ground conduits, etc. It can solve problems such as unstable cable trough laying structure, water accumulation in cable trough, and poor construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

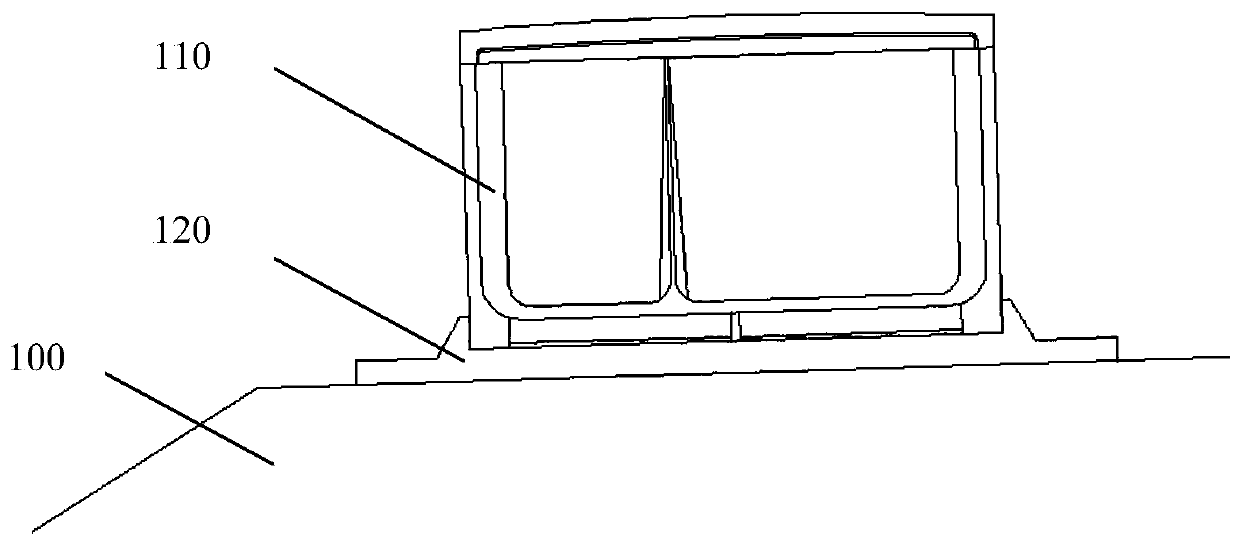

[0034] In this embodiment, the cable duct 110 is arranged on the road shoulder 100 along the extending direction of the line.

[0035] According to the present invention, adjacent sub-cable ducts are connected through pipe joints, and fixedly connected with the road shoulder 100 through the fixed backing plate 120 at the pipe joint connection. The fixed backing plate 120 is fixedly installed on the road shoulder 100 through anchor bolts. The fixed backing plate 120 is provided with a first card slot, and the cable duct pipe joint is locked into the first card slot for fixed installation.

[0036] In the construction process of laying the cable trench, the fixed backing plate 120 is first installed at the set position, and the fixed backing plate 120 is fixed to the road shoulder 100 of the foundation bed through an anchoring method. card slot. In order to improve the laying stability of the cable duct 110 , a waterproof structural adhesive is provided between the first slot ...

Embodiment 2

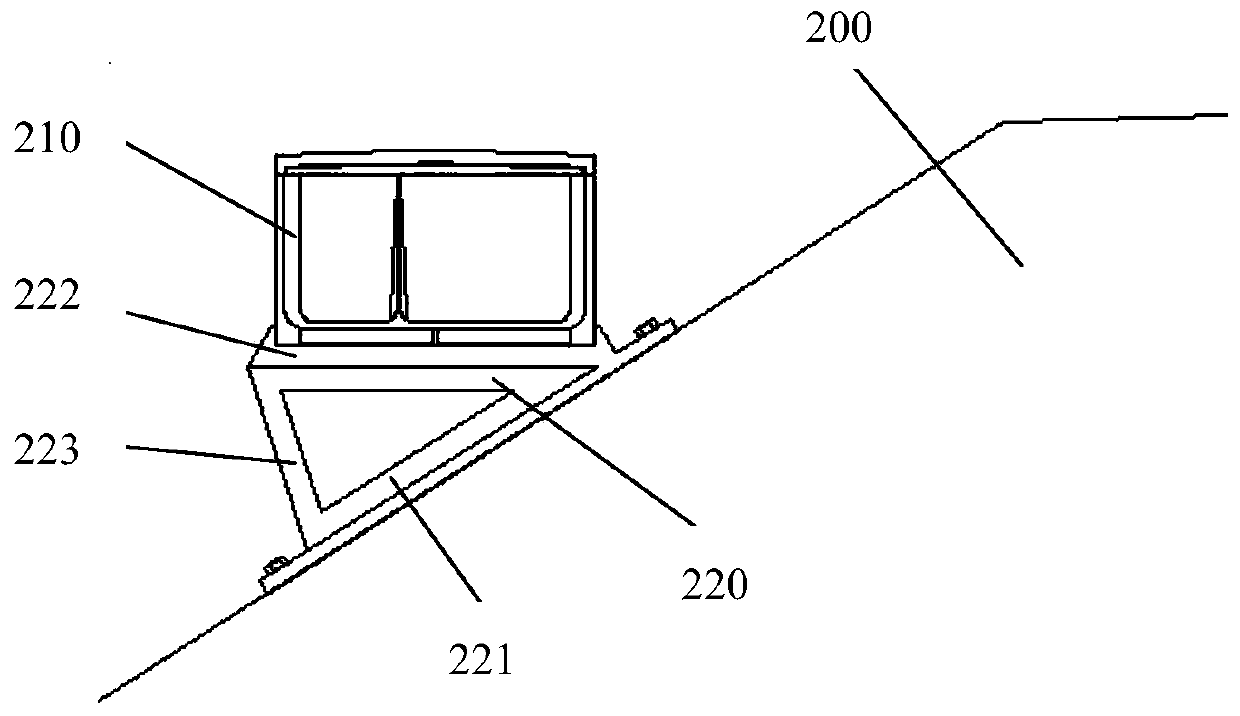

[0038] In this embodiment, a cable groove 210 is arranged on the outer side of the road shoulder 200 along the extending direction of the line.

[0039] According to the present invention, the cable duct 210 is arranged on the slope surface of the road shoulder 200 through the supporting frame 220 . Such as figure 2 As shown, the support frame 220 is fixed on the slope of the road shoulder 200 . The supporting frame 220 includes a fixing plate 221 and a supporting plate 222 connected at an acute angle, and a connecting plate 223 for connecting the fixing plate 221 and the supporting plate 222 is provided between the fixing plate 221 and the supporting plate 222 . Thus, the support frame 220 forms a stable triangular support structure, which can effectively ensure the stability of the support frame 220 for the cable duct. The acute angle between the fixed plate 221 and the support plate 222 is set according to the inclination angle of the slope surface of the road shoulder, ...

Embodiment 3

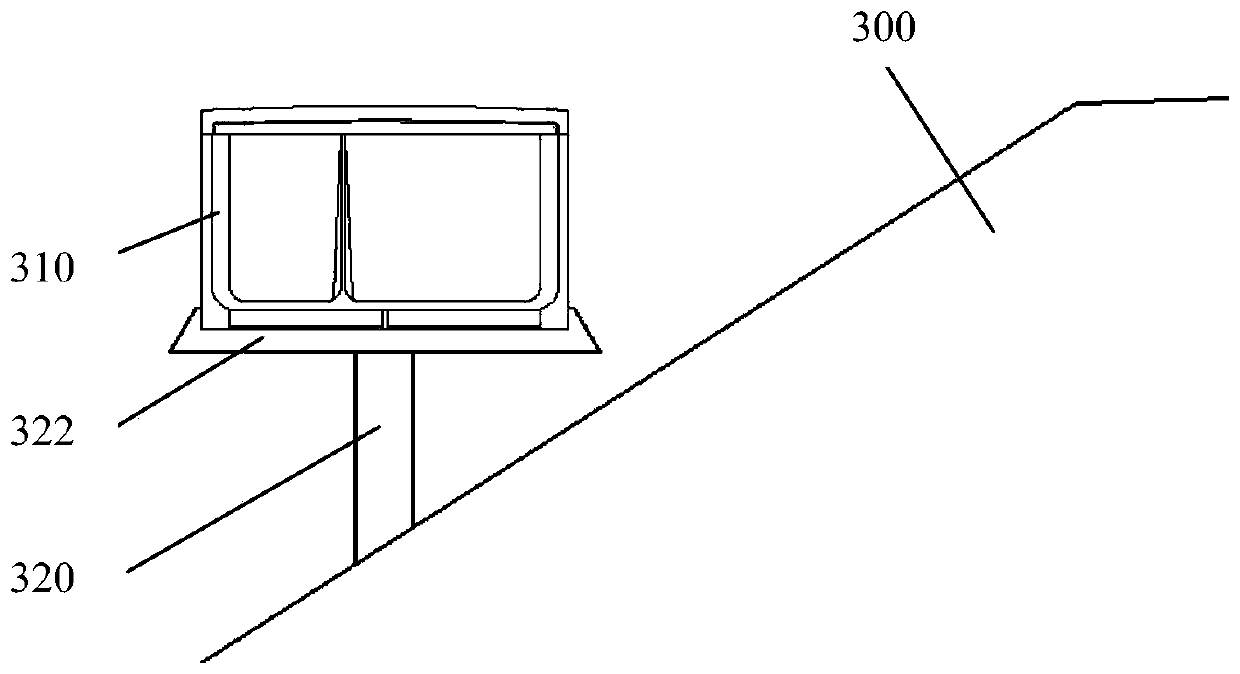

[0044] In this embodiment, a cable groove 310 is arranged on the outer side of the road shoulder 300 along the extending direction of the line.

[0045] According to the present invention, the cable duct 310 is laid on the slope surface of the road shoulder 300 through the pier 320 . Such as image 3 As shown, the buttresses 320 are fixedly arranged on the slope surface of the road shoulder 300 and evenly spaced along the longitudinal direction. In one embodiment, the buttress 320 adopts a prefabricated steel casing, preferably a seamless steel pipe. According to the invention, the steel casing is prefabricated together with the shoulder concrete. Before pouring the road shoulder construction, the steel sleeves are placed longitudinally at a distance of two meters, and then poured in the slope of the road shoulder to form the buttress 320 . The cable duct 310 is laid on the outside of the road shoulder 300 through the pier 320 and above the slope surface of the road shoulde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com