Embedded expansion valve sealing structure in high-pressure oil tank of medical X-ray generator

A high-pressure fuel tank and sealing structure technology, applied in X-ray equipment, electrical components, etc., can solve problems such as poor sealing of high-pressure fuel tanks, untimely heat dissipation, and irregular fuel tanks. , The effect of convenient after-sales maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

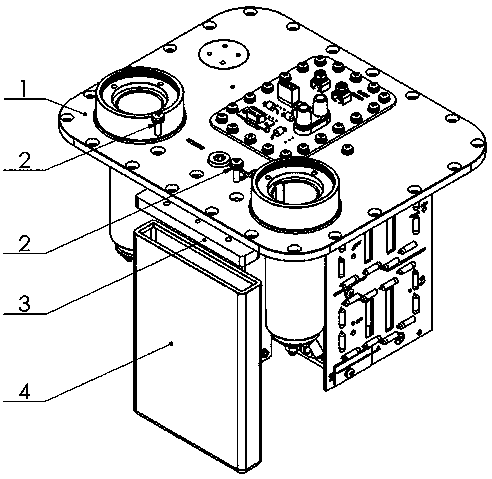

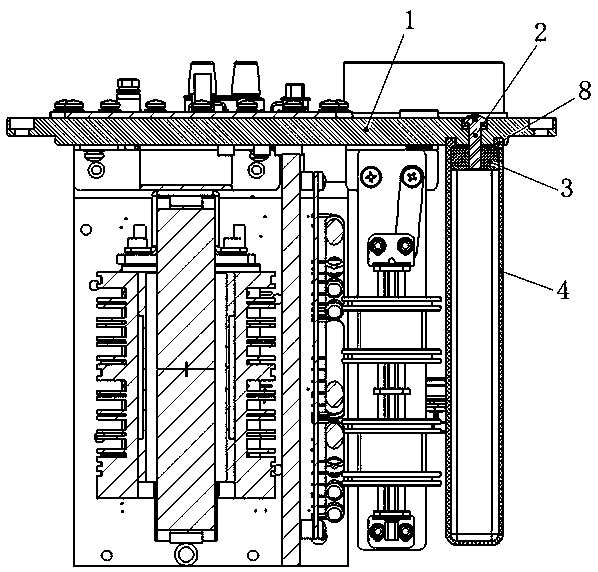

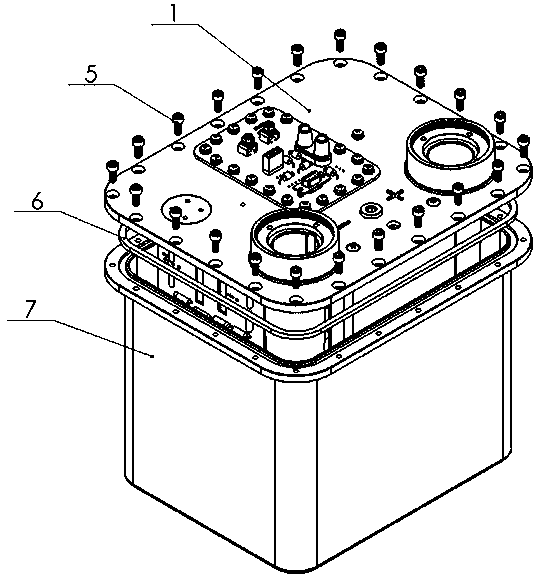

[0020] Such as Figure 1-3 As shown, a sealing structure of an embedded expansion valve in the high-pressure oil tank of a medical X-ray generator is mainly composed of a tank cover assembly 1, a cross-recessed combination screw 2, an expansion valve pressure plate 3, an expansion valve 4, an inner hexagon screw 5, and a square sealing ring 6 and the fuel tank body 7; the tank cover assembly 1 includes an integrally die-cast aluminum alloy tank cover and a circuit board, a high-voltage transformer and a filament transformer respectively fixed and assembled under the aluminum alloy tank cover; the expansion valve pressure plate 3 After being fixedly installed on the upper end of the expansion valve 4, it is fixedly installed under the aluminum alloy tank cover through the cross-recessed combination screw 2; the upper edge of the fuel tank body 7 is provided with a groove matching the square sealing ring 6, and the square After the sealing ring 6 is installed in the groove, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap