Rotary tiller tool shaft tool magazine automatic welding machine

A technology of automatic welding machine and rotary tiller, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problem that the knife magazine cannot be sent to the designated position of the knife shaft, the welding angle change cannot be satisfied, and the welding quality cannot be solved. Can not be guaranteed and other problems, to achieve the effect of reducing the labor intensity of workers, achieving firm welding, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

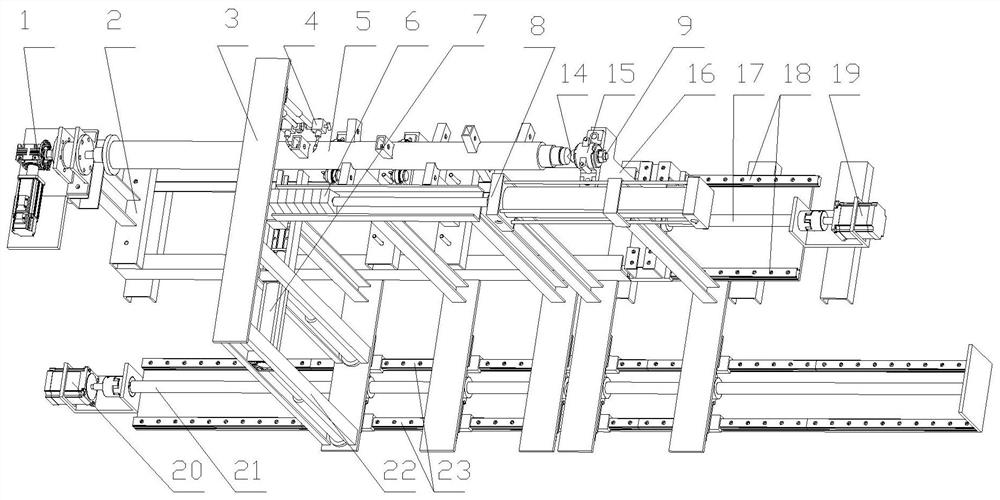

[0018] Such as figure 1 As shown, the rotary cultivator cutter shaft automatic welding machine of the present invention includes a main frame 2, a rotary indexing mechanism 1 fixedly installed on the upper left platform of the main frame 2, and a cutter shaft slidably connected to the right side of the main frame 2 Jacking mechanism 9, a transverse movement mechanism 3 located in the middle of the main frame 2 and capable of moving back and forth along the direction of the cutter shaft 5, the transverse movement mechanism 3 is provided with a knife magazine transverse feed mechanism 8, a knife magazine longitudinal feed mechanism 7 and a welding mechanism 4 .

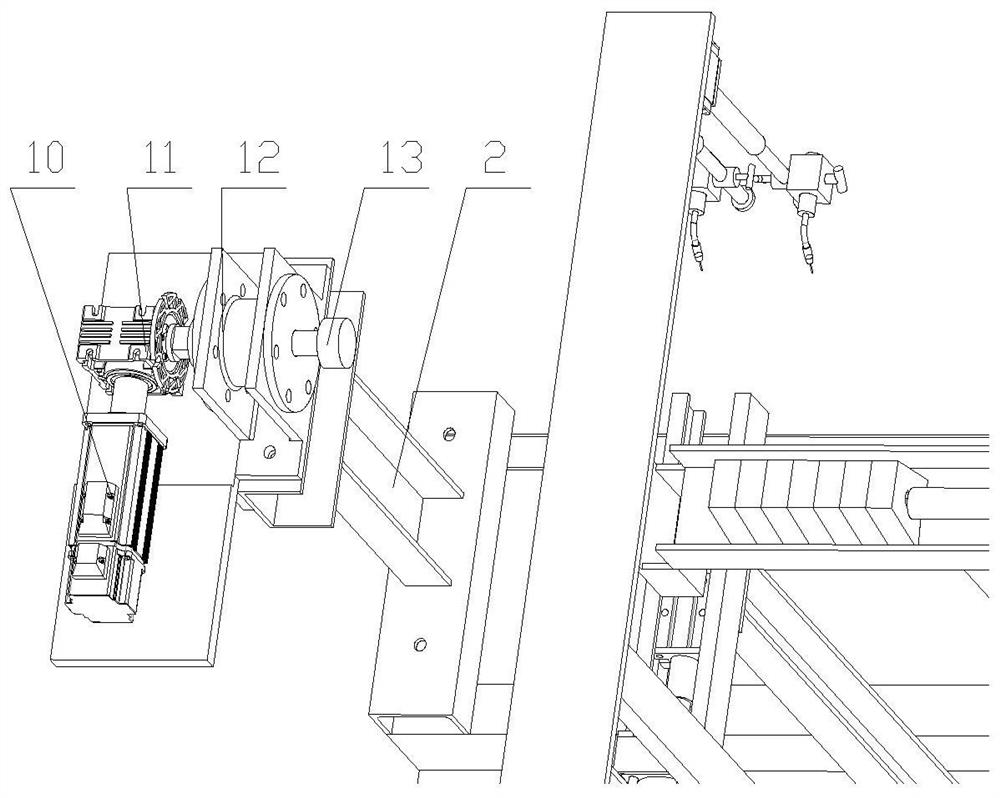

[0019] Such as figure 2 As shown, the rotary indexing mechanism 1 sequentially includes an indexing servo motor 10, a reduction box 11, and an indexing spline shaft 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com