A kind of preparation method of flywheel housing connecting plate

A technology of connecting plates and flywheel housings, applied in the field of flywheel housings, can solve problems such as easy oil leakage and reduce engine reliability, and achieve the effects of easy access, good flatness and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

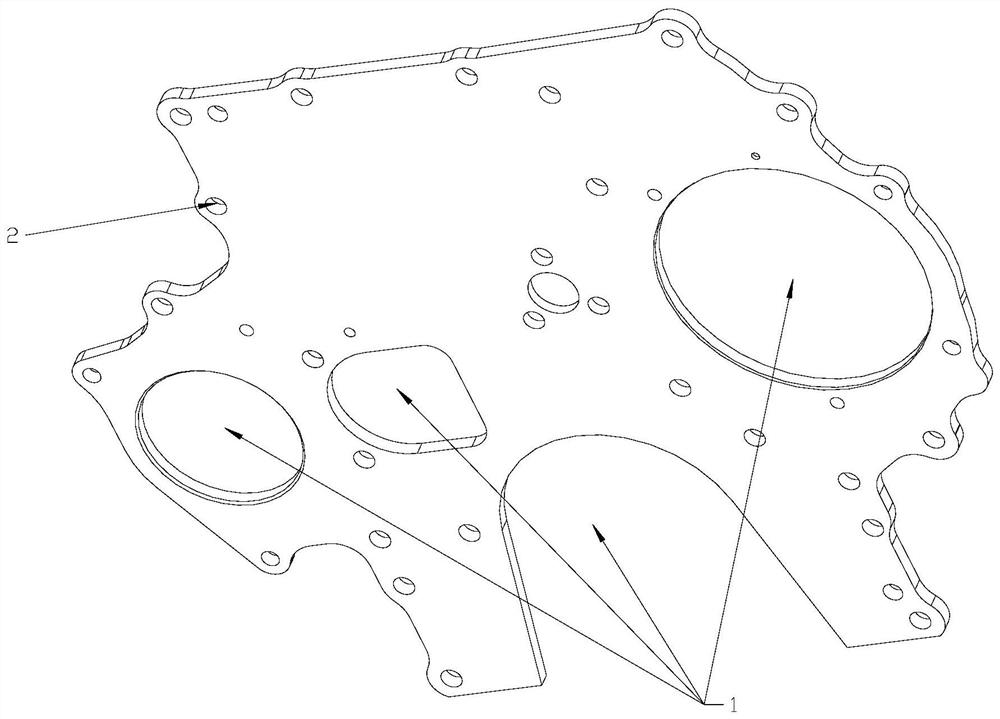

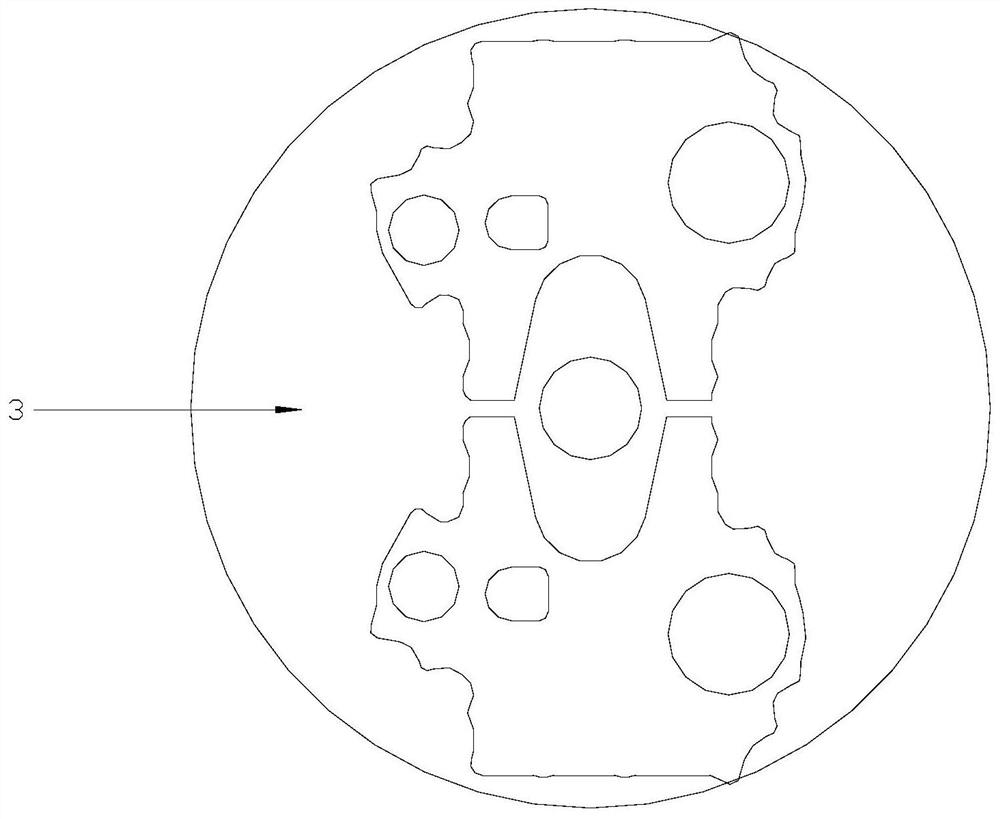

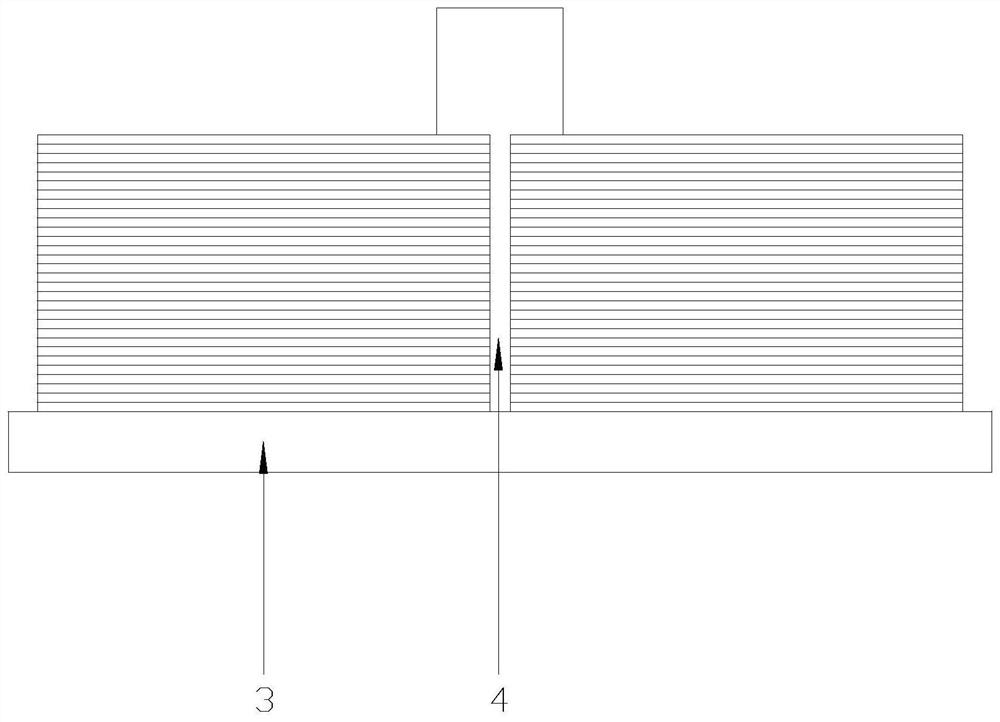

[0026] refer to figure 1 , figure 2 and image 3 , the preparation method of a kind of flywheel housing connecting plate of the present invention, comprises the steps:

[0027] a) cutting:

[0028] The No. 45 steel plate that is not easily deformed, easy to obtain, and low in cost is used, and the size, chemical composition, and surface quality of the steel plate are inspected by tape measure, vernier caliper, high-speed carbon-sulfur analyzer, and visual inspection before the process. Then, through the CNC cutting machine, several positioning holes 1 are formed on the steel plate by laser cutting to allow the gears to pass through to obtain cutting blanks, which reduces the possibility of product deformation from the beginning of the process. Cutting parameters are pre-oxygen ≥ 0.5Mp, cutting oxygen ≥ 0.7Mp, acetylene ≥ 0.1Mp, cutting speed 370-390mm / min. The first piece is sent for inspection, and the self-inspection is continued with the imitation cutting comparison sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com