Automatic grinding device for medical sterilization bin

An automatic and grinding mechanism technology, which is applied in the direction of grinding drive devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., to achieve the effect of solving the problem of low grinding efficiency and avoiding health injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

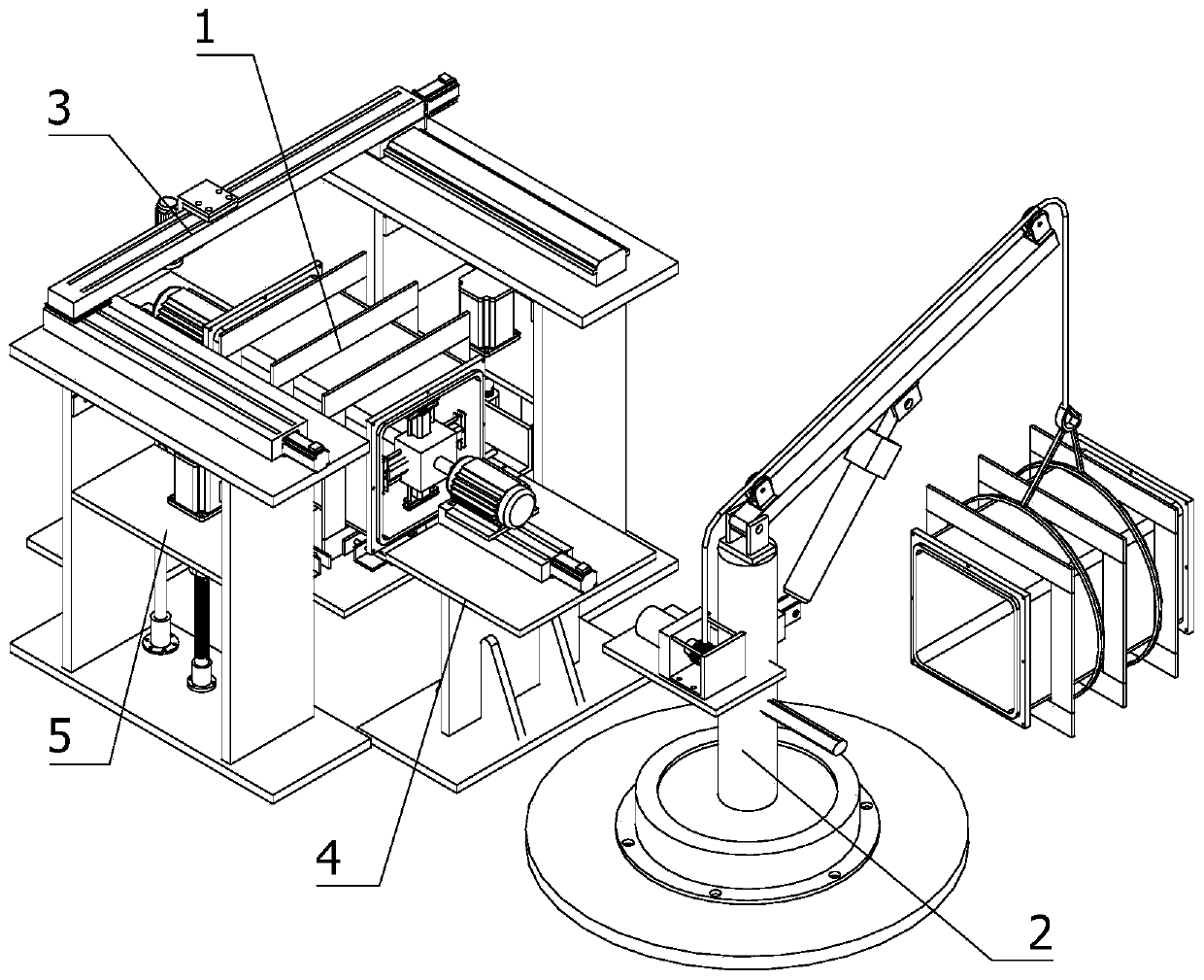

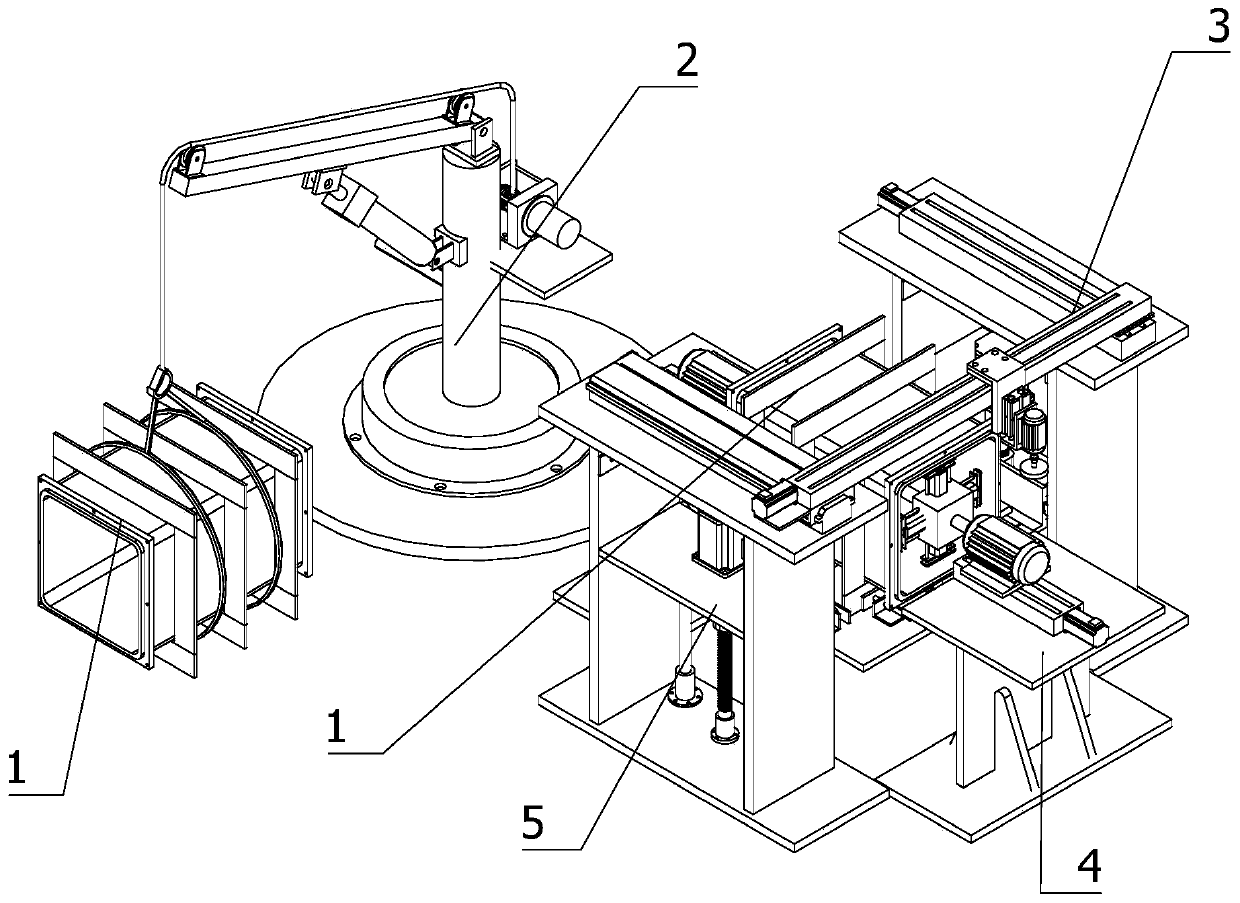

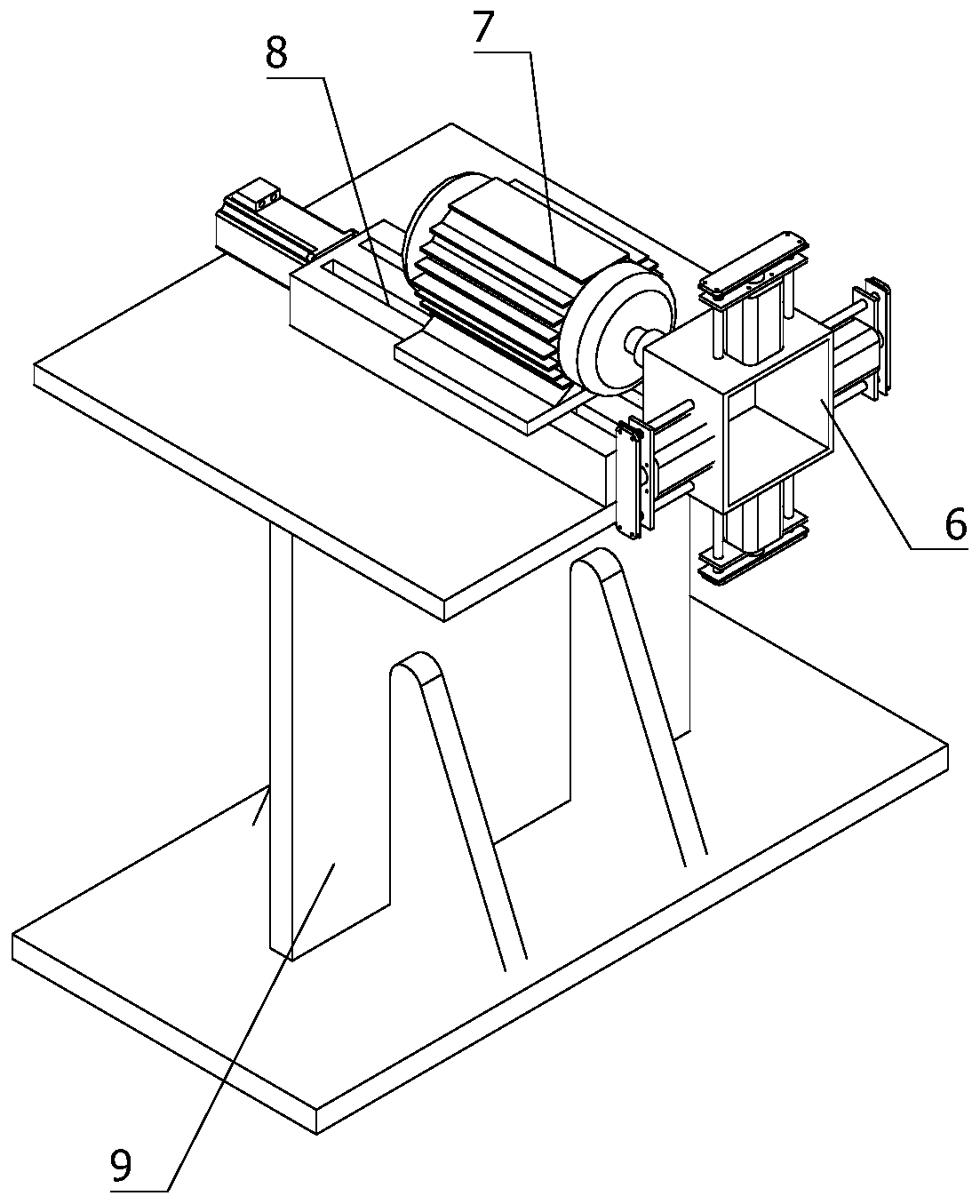

[0033] Reference Figure 1 to Figure 13 As shown, this embodiment proposes an automatic polishing device for a medical sterilization chamber, which mainly performs polishing processing for a sterilization chamber set in a low-temperature sterilization equipment. Figure 1 to 2 The mark 1 in is the sterilization chamber of the low-temperature sterilization equipment. A number of convex plates are provided on the outer periphery of the sterilization chamber 1 by welding. After the convex plates are welded on the four sides of the outer periphery of the sterilization chamber 1, the welding However, a lot of protrusions and burrs are generated on both sides of the convex plate. Therefore, after the convex plate is welded on the outer periphery of the sterilization chamber 1, it is usually necessary to polish the welding part. The aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com