A high-efficiency and environmentally friendly plastic injection molding machine

A technology of environmentally friendly plastics and injection molding machines, applied in the field of industrial production, can solve problems such as burrs, difficult to organize and place, and increase in processing time of items, and achieve the effects of reduced processing time, safe and convenient use, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

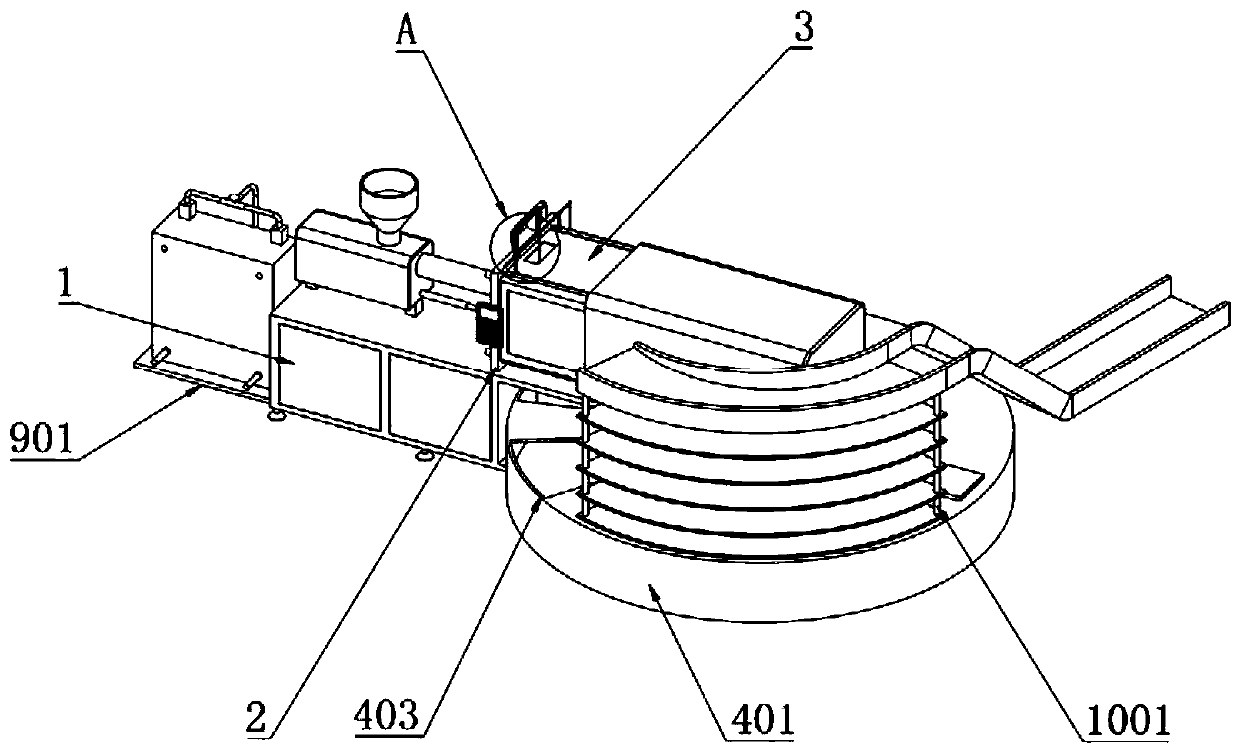

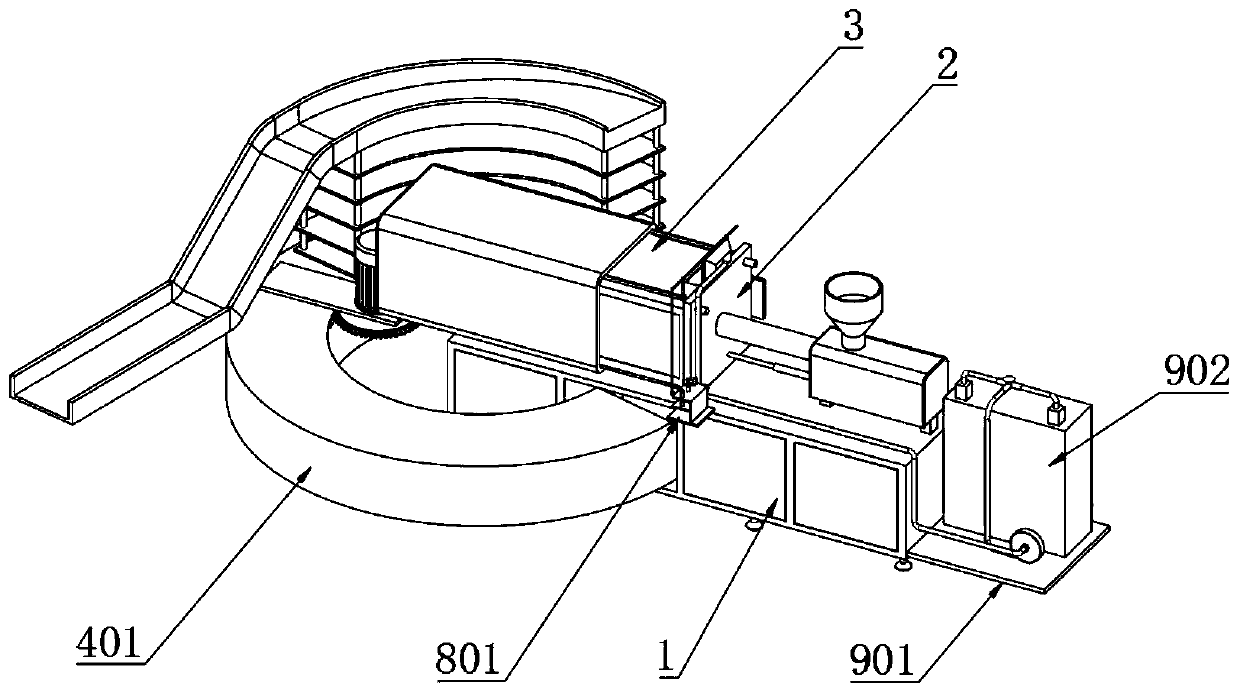

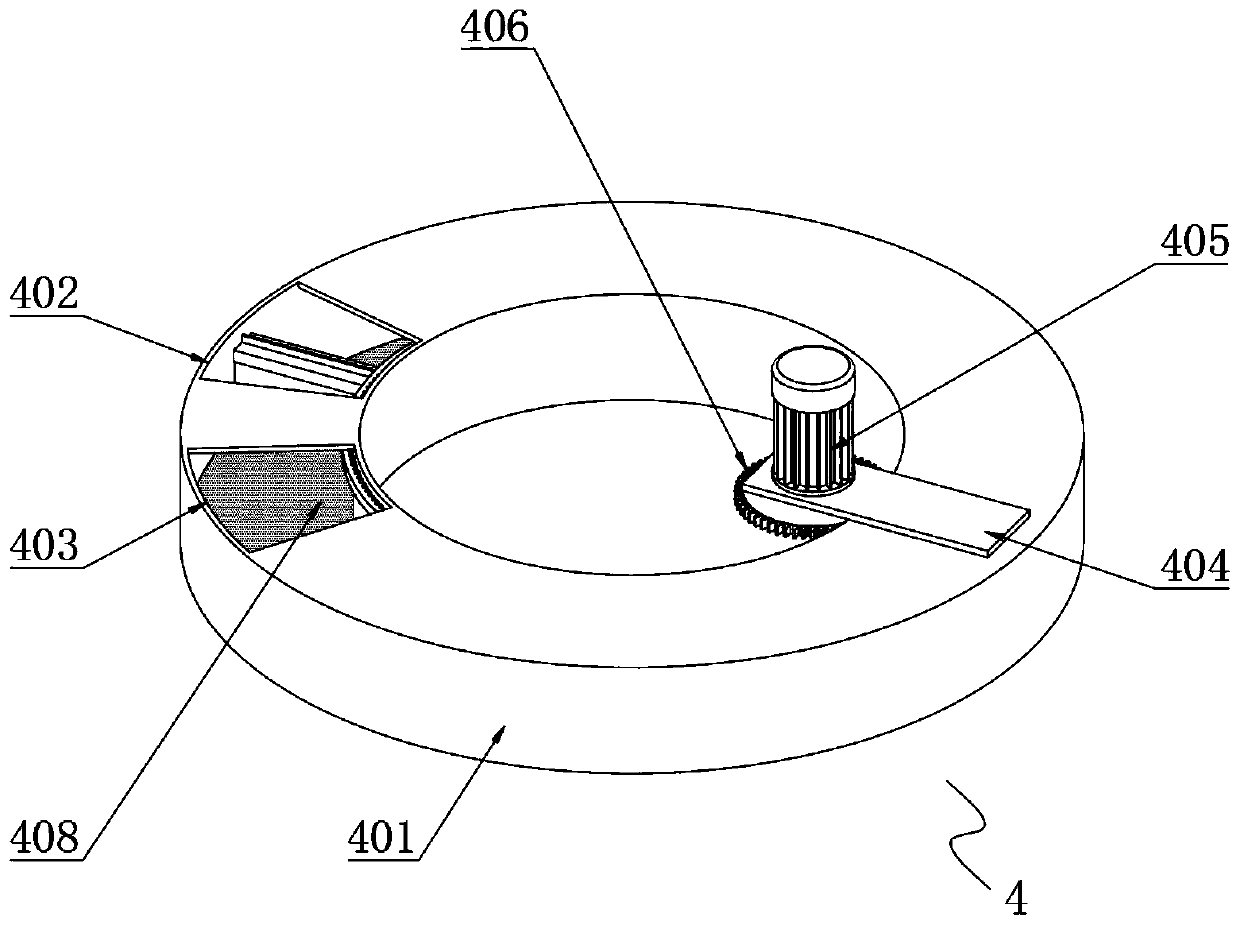

[0053] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a high-efficiency and environmentally friendly plastic injection molding machine, including an injection molding machine base 1, an installation wall panel 2 and an inner box body 3, an installation wall panel 2 is installed in the middle of the top end of the injection molding machine base 1, and the installation wall An inner box body 3 is installed on one side of the board 2, and the installation wall panel 2 is located inside the inner box body 3, and a processing mold is arranged inside the inner box body 3, and the barrel and the feeding mechanism are installed on the other side of the installation wall panel 2. When the injection molding machine is processed, from Plastic raw materials are put into the feeding hopper and heated, and the screw conveying rod in the machine barrel extrudes the hot-melted viscous plastic into the mold on the side of the wall panel 2 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com