Variable wheel diameter mechanism

A wheel diameter and variable technology, applied in the direction of wheels, motor vehicles, tire parts, etc., can solve the problems of easy subsidence of the chassis, affecting the field operation efficiency, operation quality, and easy tire slippage, etc., to improve the chassis ground clearance, The effect of improving field passing performance and reducing wheel slip rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

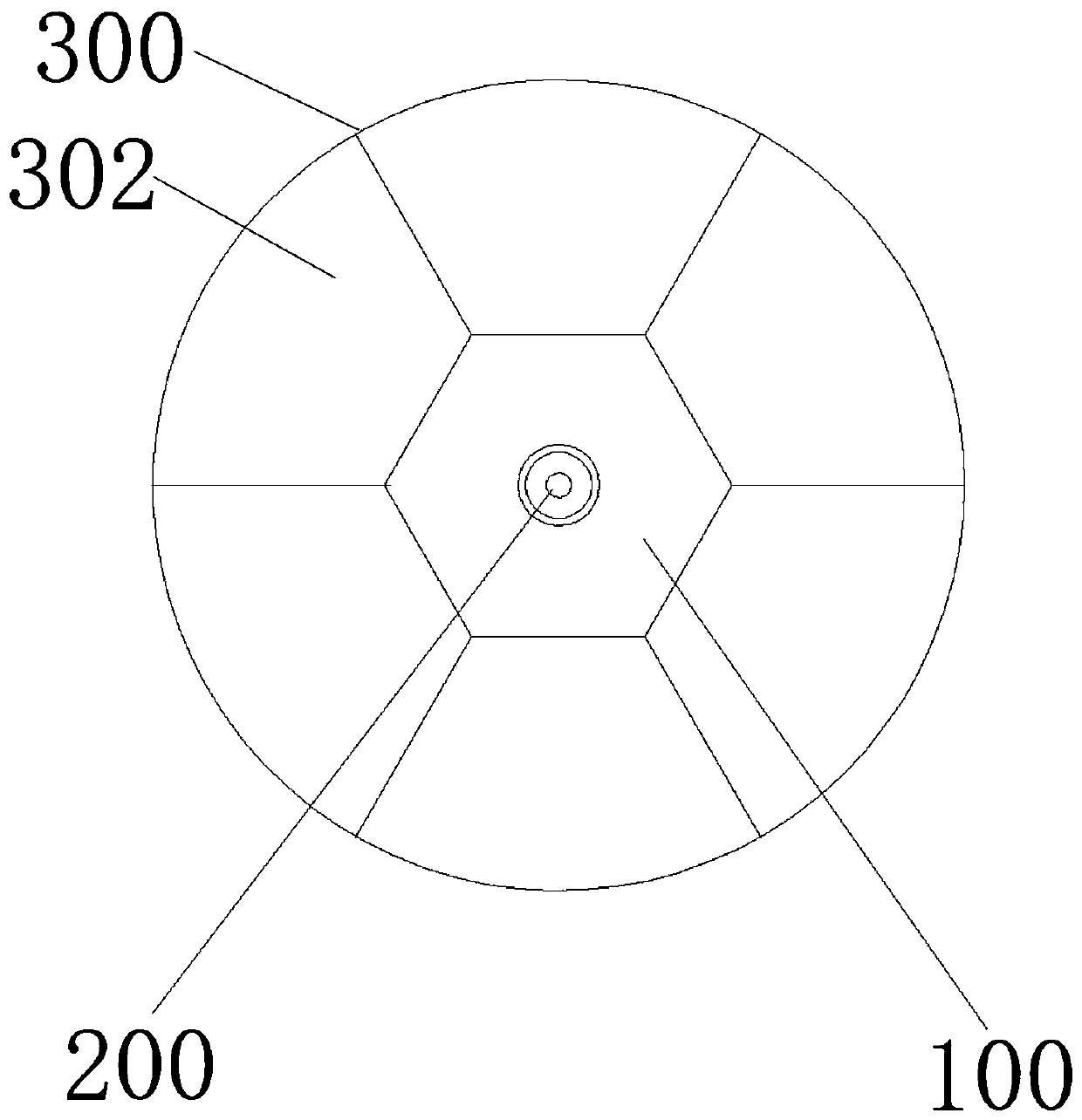

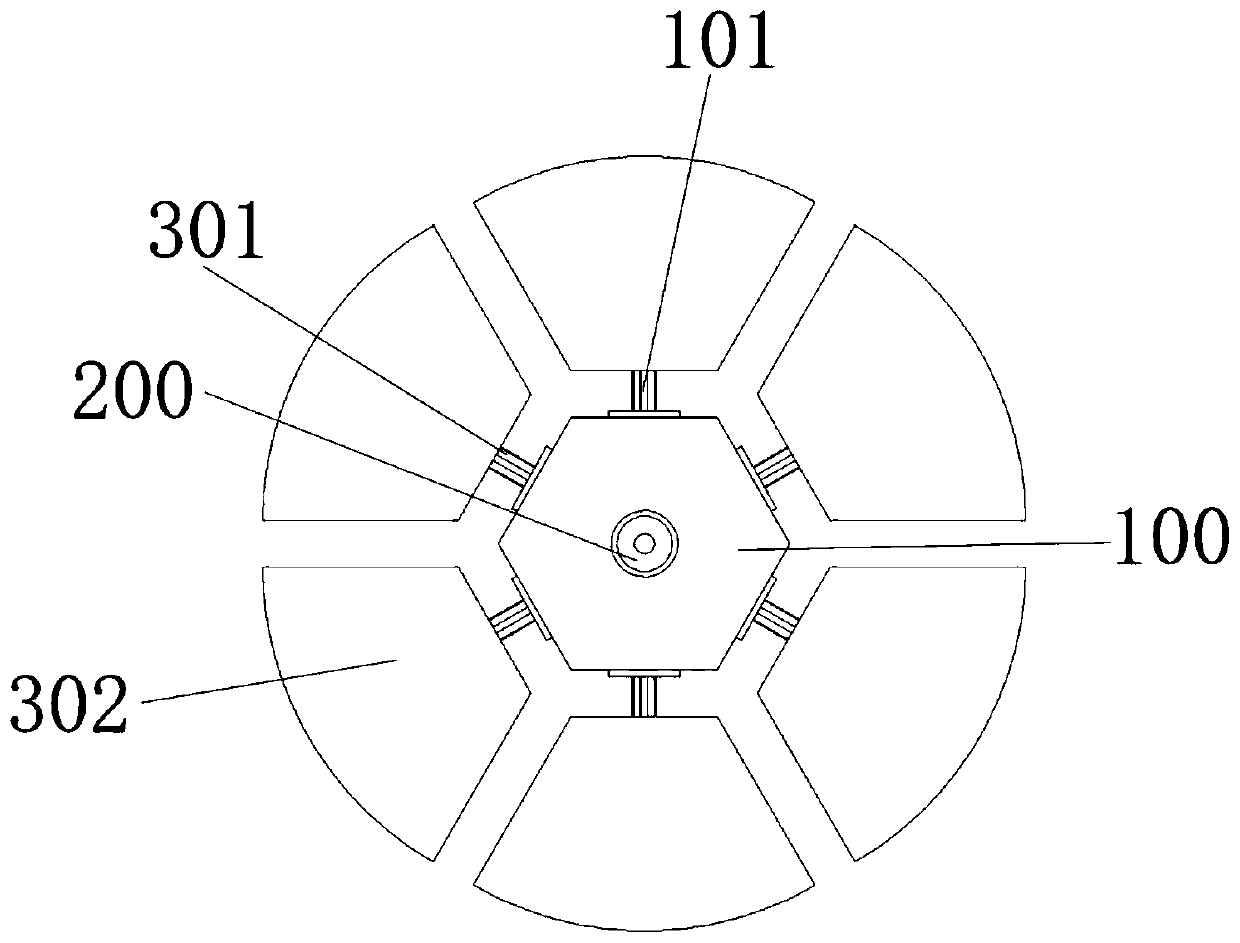

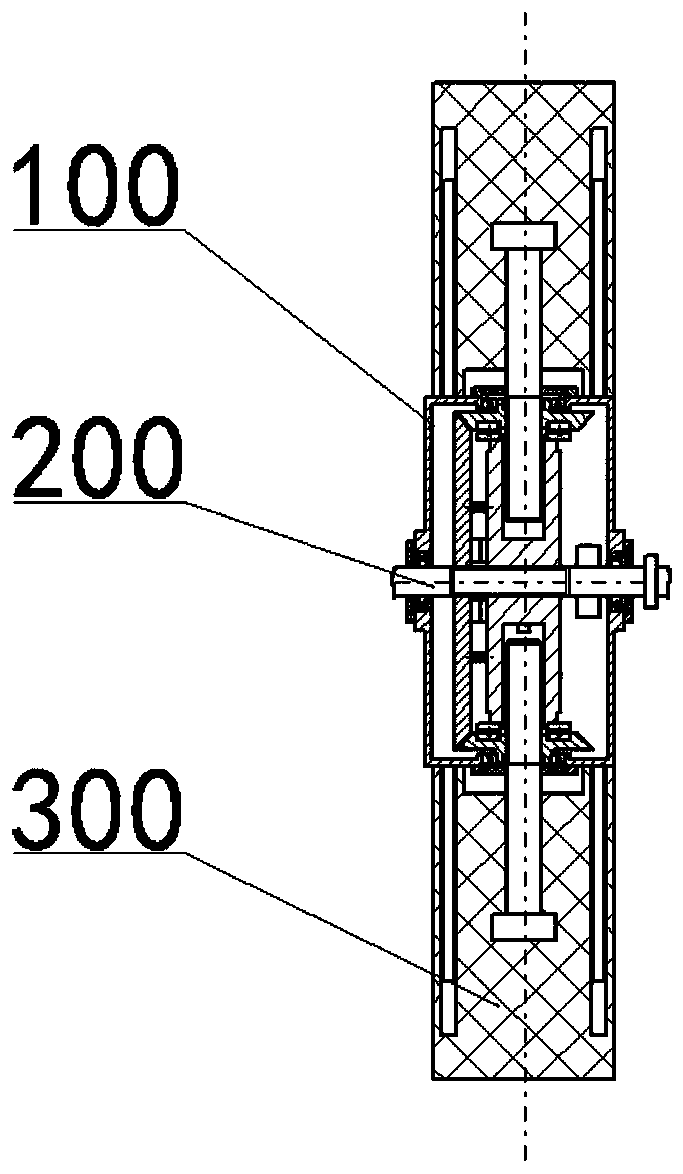

[0037] Figure 1a It is the outline drawing of the front wheel with reduced diameter. Such as Figure 1a As shown, a variable wheel diameter mechanism of the present invention includes a hub component 100 , a drive shaft 200 and a tire component 300 . The hub component 100 is connected to the driving shaft 200 through a spline, and the cross section of the hub component 100 is a regular polygonal structure. In the present invention, the hub component 100 is a regular hexagonal structure. The tire component 300 includes several tire blocks 302 equally divided, and the number of the tire blocks 302 corresponds to the number of sides of the hub component 100; the outer side of the tire block 302 is an arc structure, and the inner side is a The tire blocks 302 are respectively installed on the corresponding side surfaces of the hub component 100 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com