A deep sea equipment buoyancy adjustment system and its working method

A technology of buoyancy adjustment and working method, which is applied in the directions of fluid pressure actuation system components, mechanical equipment, transportation and packaging, etc., can solve the problems of shortening the underwater working time of deep-sea equipment, underutilizing seawater pressure, and consuming more energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

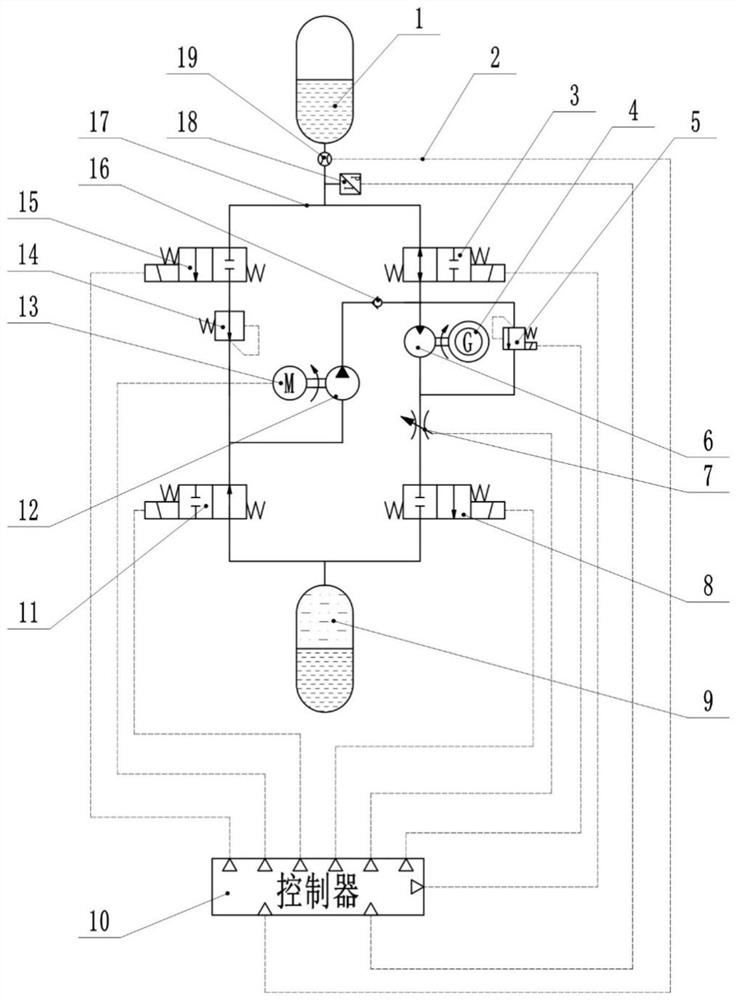

[0069] A buoyancy adjustment system for deep sea equipment, such as figure 1 As shown, it includes buoyancy oil bag 1, oil outlet normally open electromagnetic reversing valve 3, overflow valve 5, hydraulic motor 6, throttle valve 7, oil outlet normally closed electromagnetic reversing valve 8, oil storage oil Capsule 9, controller 10, oil inlet normally open electromagnetic reversing valve 11, hydraulic pump 12, pressure reducing valve 14, oil inlet normally closed electromagnetic reversing valve 15, check valve 16, pressure transmitter 18 and flow meter 19;

[0070] The oil storage bag 1 is respectively connected with the normally closed electromagnetic reversing valve 8 of the oil outlet and the normally open electromagnetic reversing valve 11 of the oil inlet, and the oil inlet of the hydraulic pump 12 is respectively connected with the normally open electromagnetic reversing valve of the oil inlet Valve 11 and pressure reducing valve 14, the oil outlet of hydraulic pump...

Embodiment 2

[0074] A buoyancy adjustment system for deep sea equipment, the structure is as shown in Example 1, the difference is that the oil storage tank 9 is a piston structure, one end is an oil storage chamber, the other end is a vacuum negative pressure chamber, and the pressure is 0.5 standard Atmospheric pressure, the volume of the buoyant oil bag 1 changes with the internal oil volume.

Embodiment 3

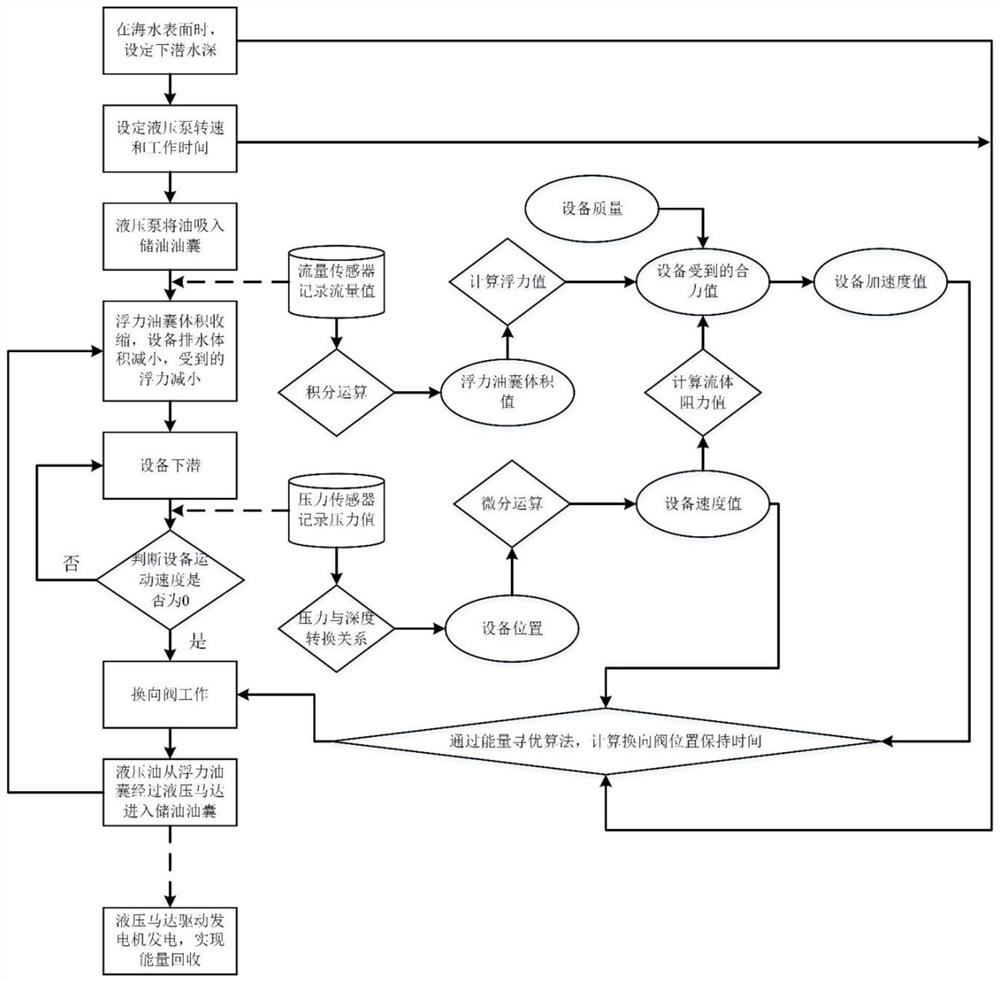

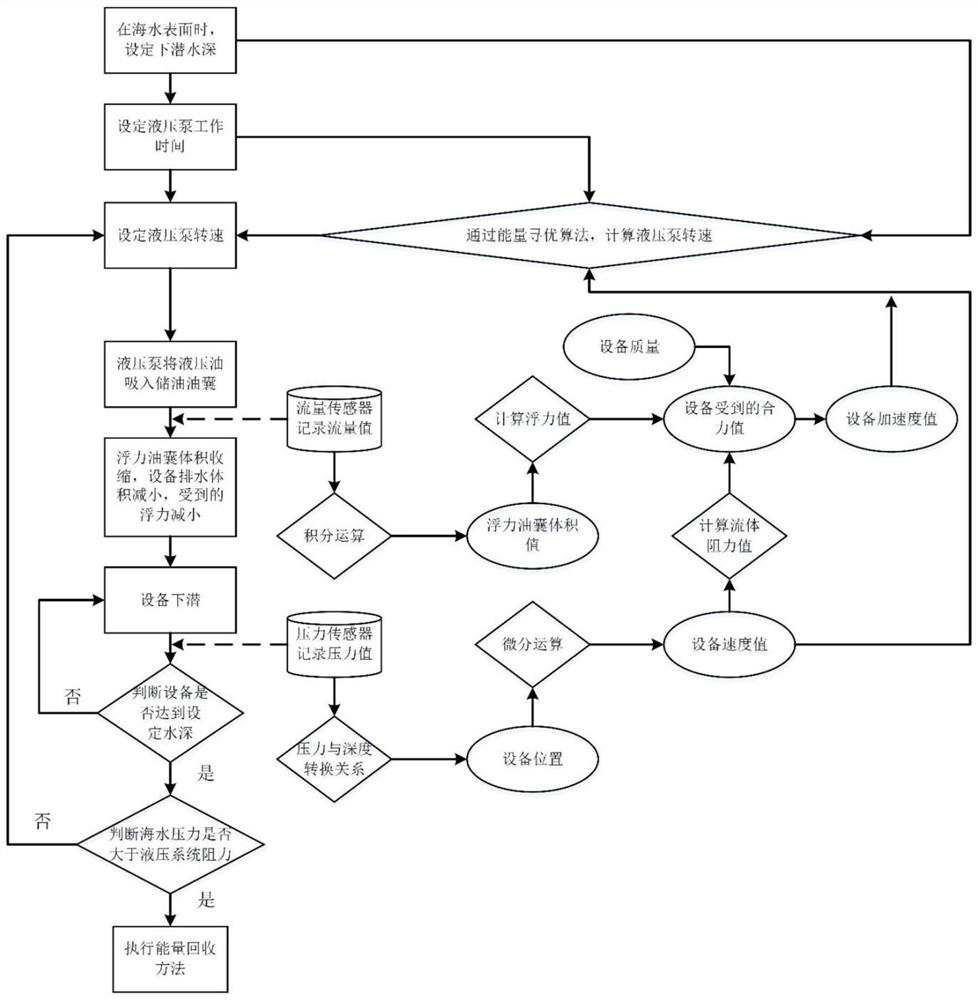

[0076] A working method of a buoyancy adjustment system for deep sea equipment. On the sea surface, when the damping of the hydraulic system is small, the controller 10 drives the normally closed electromagnetic reversing valve 8 at the oil outlet to reversing, and sends the overflow to the overflow valve 5 signal, send a throttling signal to the throttle valve 7, so that the hydraulic oil enters the oil storage bag 9 from the buoyancy oil bag 1 through the overflow valve 5 under the action of negative pressure; when the damping of the hydraulic system is large, the controller 10 Drive oil outlet normally open electromagnetic reversing valve 3, oil outlet normally closed electromagnetic reversing valve 8, oil inlet normally open electromagnetic reversing valve 11 and oil inlet normally closed electromagnetic reversing valve 15 to perform switching At the same time, it sends a speed signal to the motor 13, an overflow signal to the relief valve 5, and a throttling signal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com