Elastic woven fabric

A technology of woven fabrics and stretch, which is applied in the field of stretch woven fabrics and weft double-weave structure woven fabrics, can solve the problems of poor heat conduction and moisture permeability, inconsistent shrinkage, poor wearing comfort, etc. Good physical properties and good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail in conjunction with the embodiments, but the implementation of the present invention is not limited thereto.

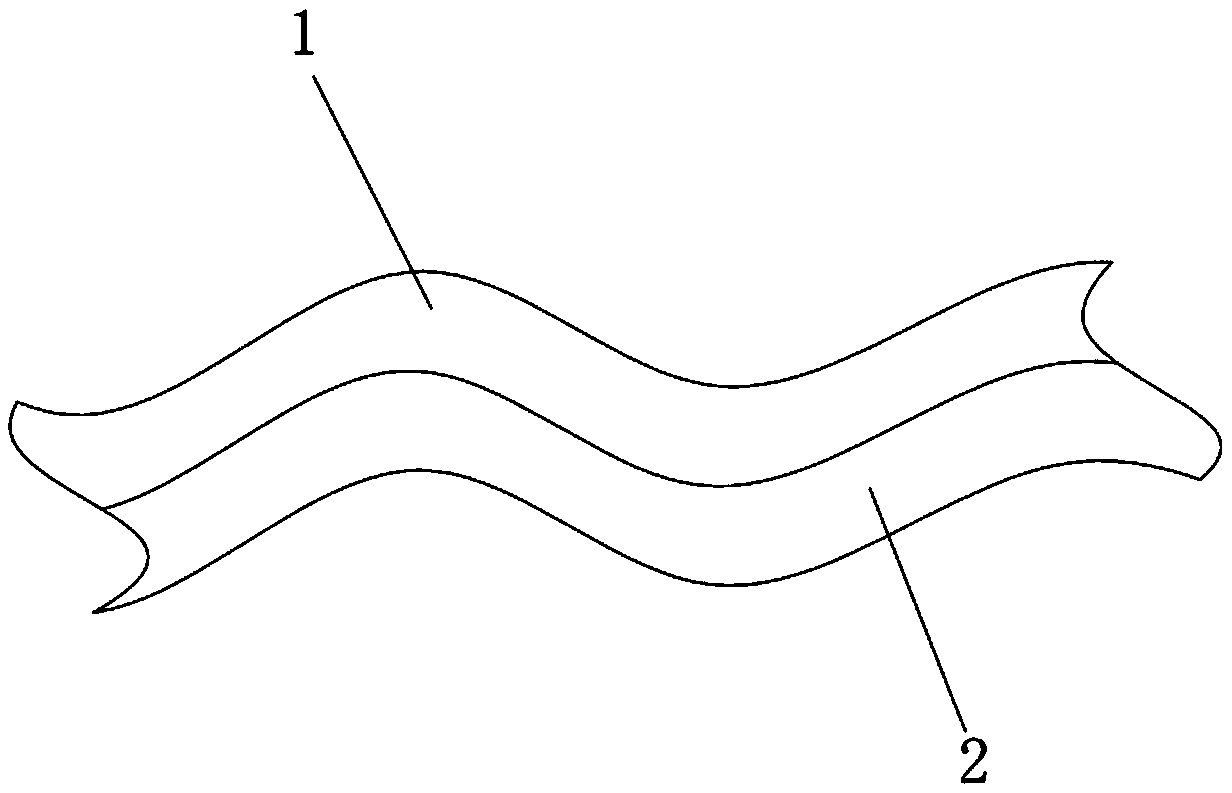

[0017] The elastic woven fabric provided by the present invention is used as an elastic sports fabric, has a weft double weave structure, and is composed of a surface layer 1 and an inner layer 2 . The warp yarns used in the surface layer and the inner layer are the same, all of which are high-elastic Lycra spandex yarns; the surface weft is tencel fiber yarn, and the inner weft is linen yarn; the arrangement ratio of the surface weft and the inner weft is 1 to 3:1, preferably It is 2:1, the tencel fiber yarn is 11.1~16.7tex, and the linen yarn is 18-36 public count.

[0018] In order to achieve a better longitudinal natural corrugation effect on the fabric, the linen yarn is a twisted linen yarn, and the tencel fiber yarn is an untwisted tencel fiber yarn. During the fabric finishing process, the prestress of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com