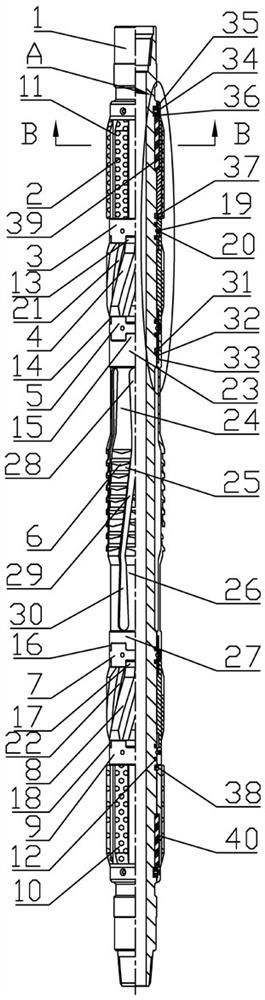

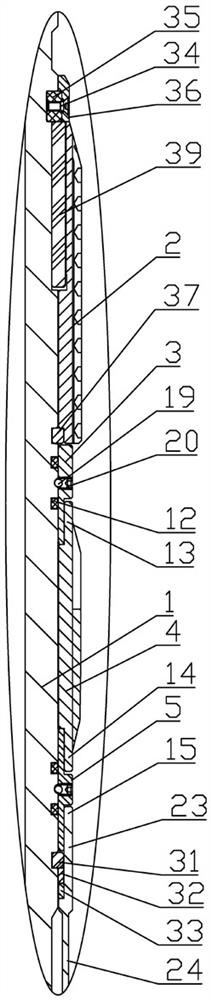

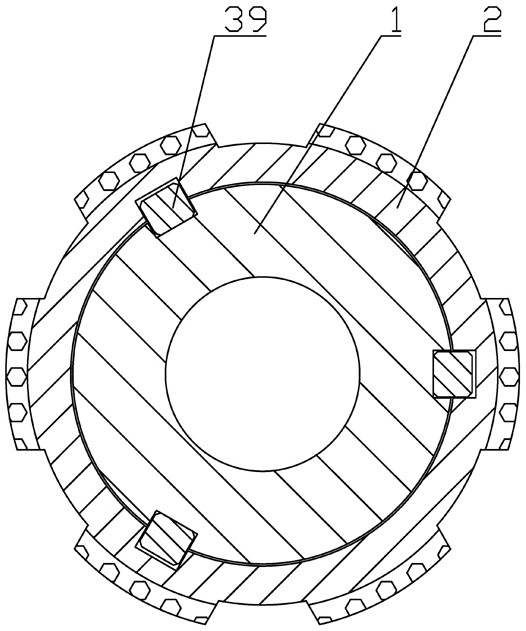

Integral rotatable scraper device

A rotary scraping, integrated technology, applied in drilling pipe, casing, wellbore/well components, etc., can solve the problem that the scraper cannot rotate downhole tools to enter the well at the same time, and achieve the effect of reasonable structure and ingenious concept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0019] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of front, back, up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0020] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0021] as attached figure 1 , 2 , 3, and 4, the integral rotatable scraper device includes a mandrel 1, an upper milling cylinder 2, a first bearing outer cylinder 3, an upper centralizing cylinder 4, a second bearing outer cylinder 5, a scraper cylinder, a third The bearing outer cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com