Air intake system of power system and engineering machinery

A power system and air intake system technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems of increased air intake resistance of the engine, black smoke from the engine, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

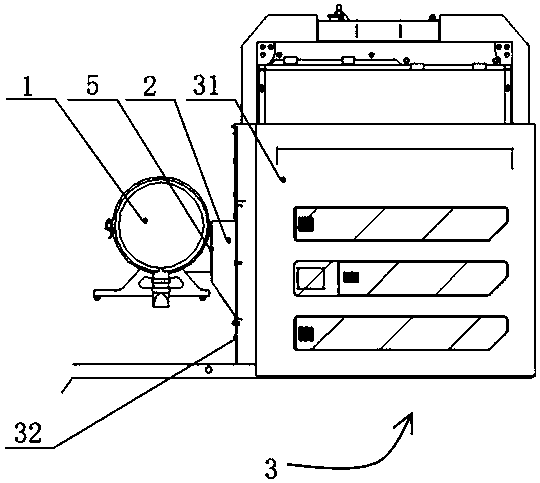

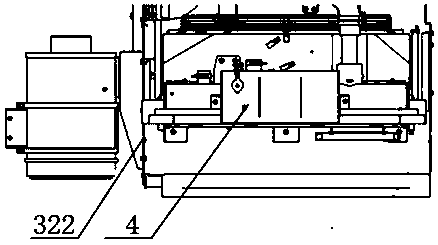

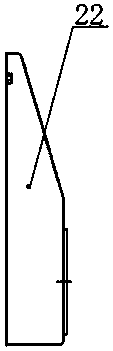

[0052] figure 2 It is a structural schematic diagram of the air intake system of the power system provided by this embodiment from a perspective, image 3 It is a schematic diagram of the internal partial structure of the air intake system of the power system provided in this embodiment, Figure 4 A structural schematic view of the air deflector and the heat dissipation engine room in the air intake system of the power system provided by this embodiment, Figure 5 for Figure 4 side view, Figure 6 A schematic structural view of the side panel in the air intake system of the power system provided by this embodiment at a viewing angle, Figure 7 The structure diagram of the cabin partition in the air intake system of the power system provided in this embodiment at one angle; please refer to Figure 2-7 , the present embodiment provides an air intake system of a power system, the air intake system of the power system of this embodiment includes an air filter 1, a shroud 2 a...

Embodiment 2

[0066] This embodiment provides a construction machine, which includes the intake system of the power system described in the first embodiment. The construction machine in this embodiment may be a rotary drilling rig.

[0067] The air intake system of the above-mentioned power system includes an air filter, a shroud and a cooling engine room;

[0068] One end of the air filter is connected to the engine intake pipe, the other end of the air filter is connected to one end of the wind deflector, and the other end of the wind deflector is connected to the heat dissipation cabin, and the heat dissipation engine compartment includes a heat dissipation The cabin body, the first cabin partition arranged in the heat dissipation cabin body, and the second cabin partition arranged on the outer surface of the heat dissipation cabin body, the first cabin partition is provided with a first air inlet, A second air inlet connected to the wind deflector is opened on the second cabin partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com