Cold-proof anti-freezing stainless steel tube for automobile

A technology for stainless steel pipes and automobiles, applied in the direction of anti-corrosion/anti-rust protection of pipelines, pipes, rigid pipes, etc., can solve the problems of inconvenient installation of stainless steel pipes, manual bending, unfavorable stainless steel pipes, etc., to improve cold and frost resistance, and improve flexibility. Flexibility, easy bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

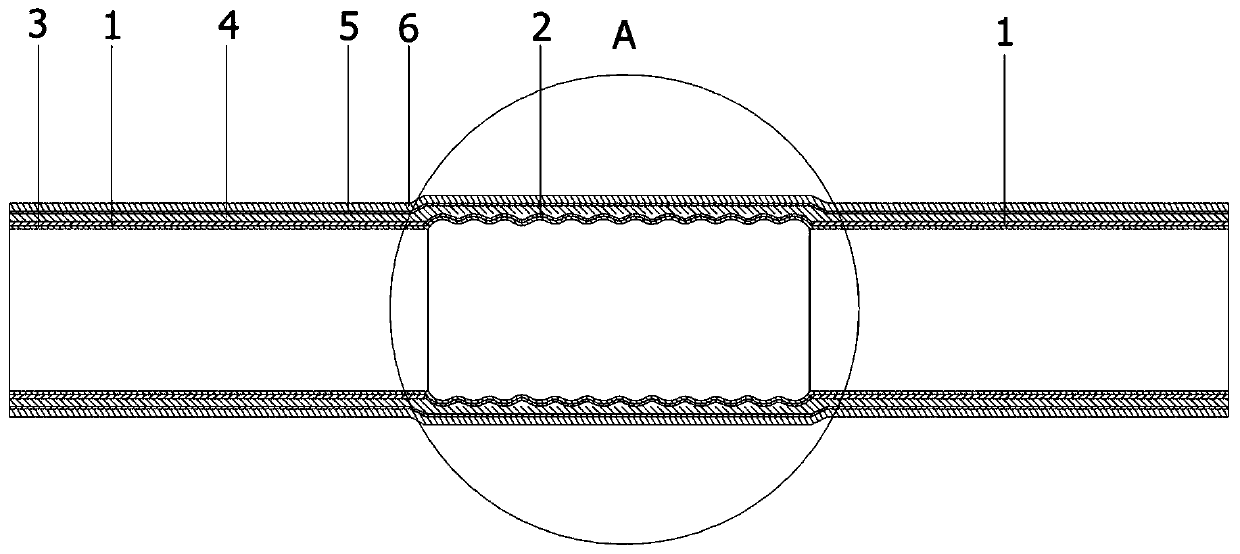

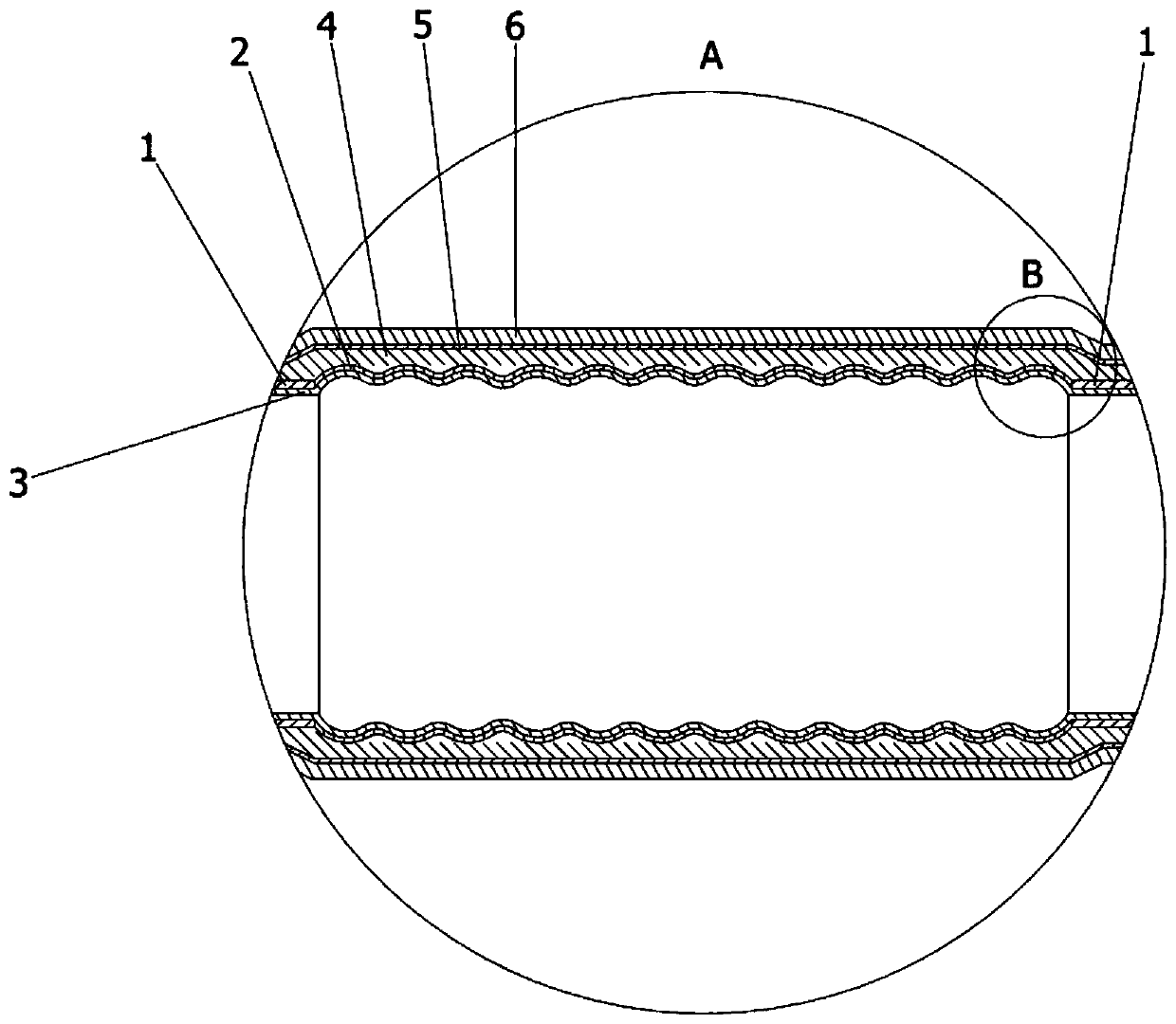

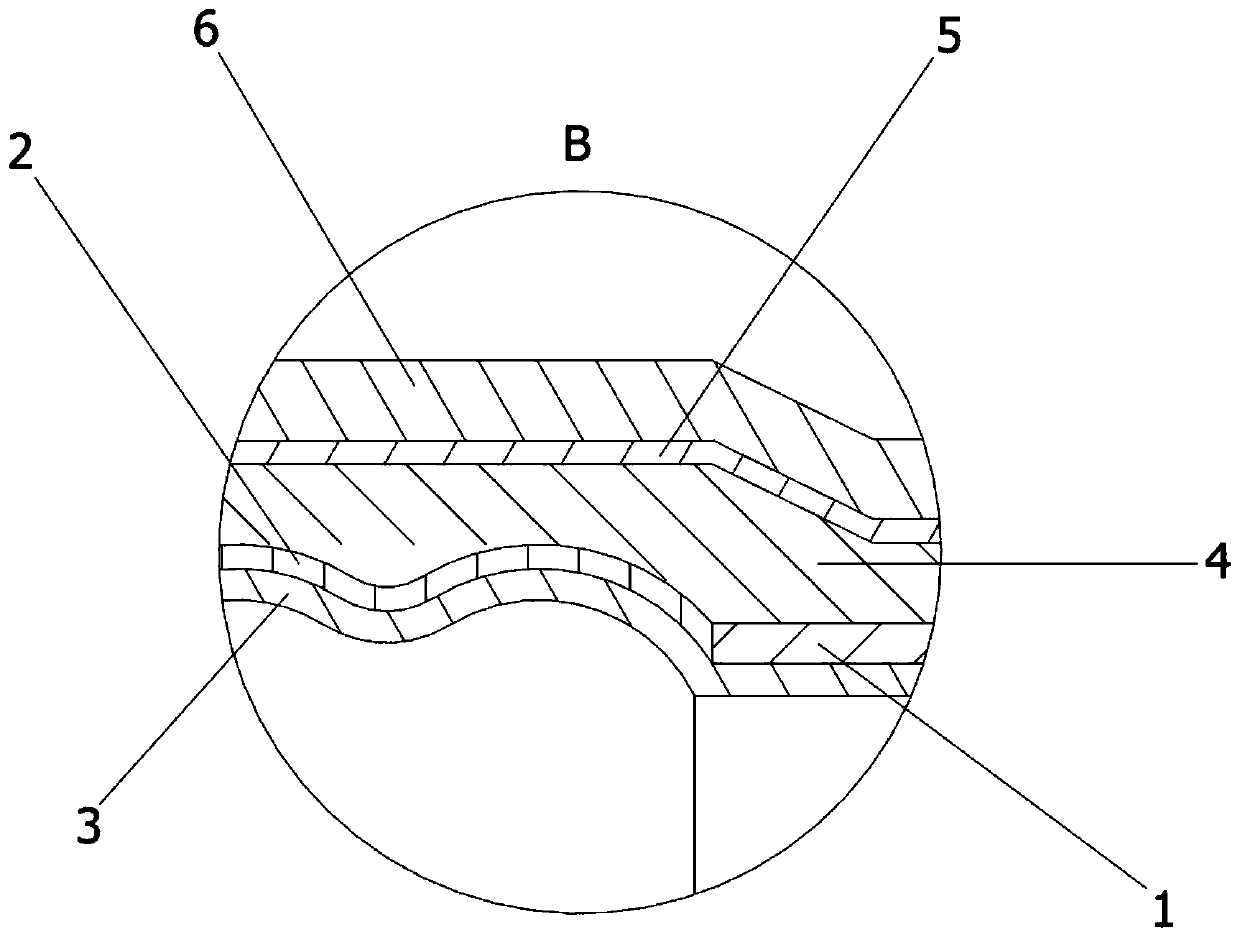

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The invention provides a kind of anti-cold and anti-freeze stainless steel pipe for automobiles, comprising a stainless steel pipe main body 1, an aluminum pipe 2, an anti-corrosion coating 3, an elastic insulation layer 4, an adhesive 5, a rubber protective layer 6 and a rectangular anti-skid strip 7; the stainless steel pipe The number of the main body 1 is two in total, and one aluminum tube 2 is welded between the opposite surfaces of the two stainless steel tube main bodies 1, as shown in the attached Figure 6 As shown; the inner peripheral surfaces of the two stainless steel pipe main bodies 1 and the aluminum pipe 2 are all coated with an anti-corrosion coating 3, and the outer peripheral surfaces of the two stainless steel pipe main bodies 1 and the aluminum pipe 2 are all sleeved with elastic insulation layers 4 , as attached figure 1 to attach image 3 As shown; the outer peripheral surface of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com