Online monitoring sensor for corrosion depth of heating surface of boiler

A technology for monitoring sensors and corrosion depth, applied to thermometers, instruments, thermometers, etc. that are directly sensitive to heat and electric/magnetic components, can solve the problem of inability to measure the corrosion and thinning of boiler tubes, and achieve safe and stable operation. Easy to measure and reduce the effect of non-stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

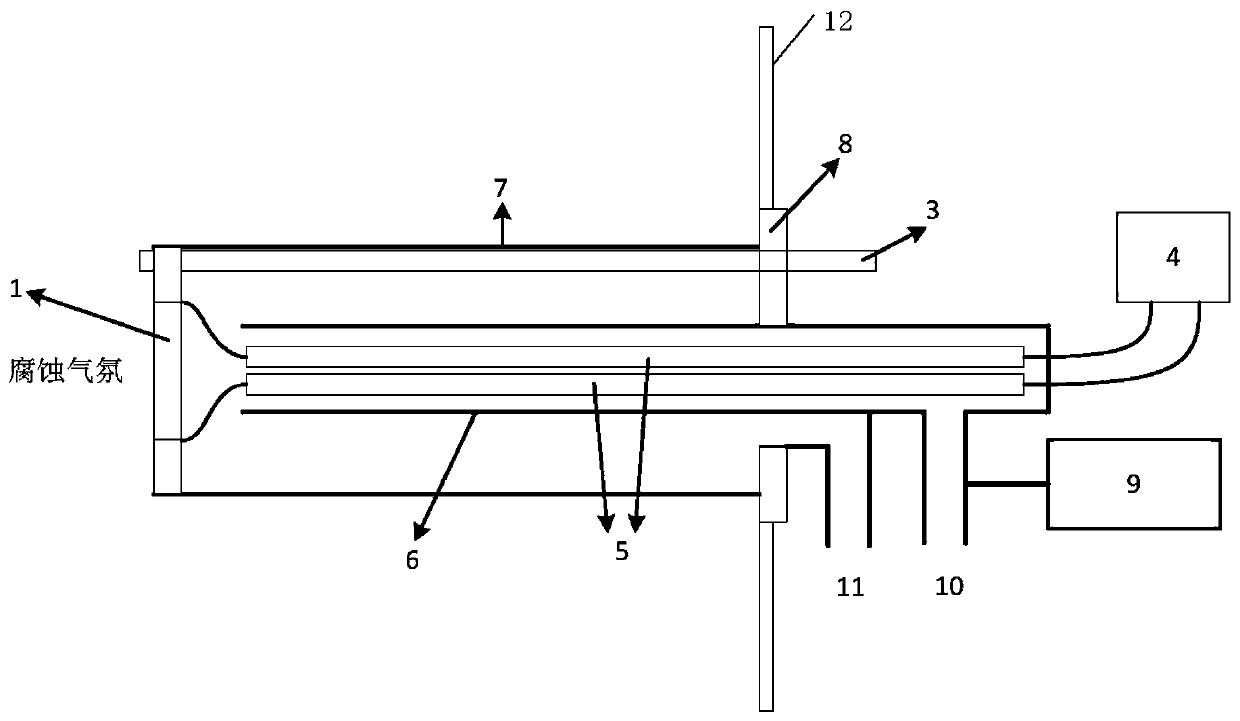

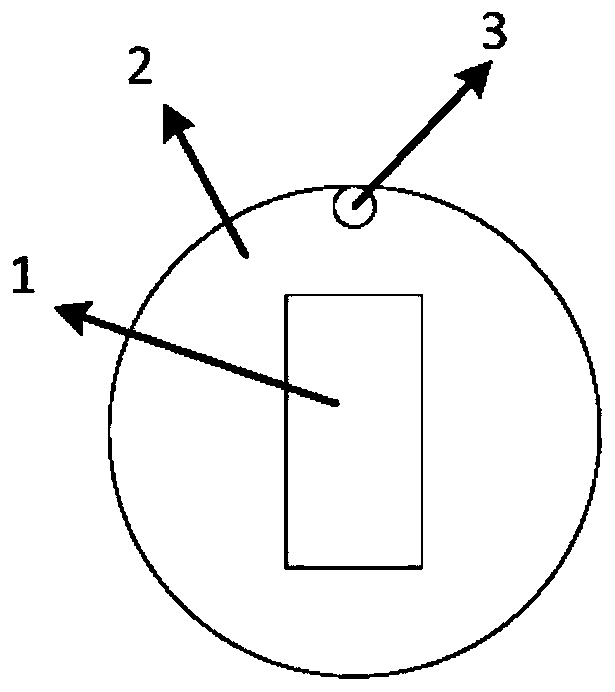

[0027]An on-line monitoring sensor for the corrosion depth of the heating surface of a boiler provided by the present invention includes a test piece 1, a sealed ceramic 2, a thermocouple 3, a digital micro-ohmmeter 4, a high temperature resistant wire 5, an air intake pipe 6, a hollow cavity 7, a sealed Flange 8 and temperature control module 9; wherein, the piece 1 to be tested is fixed in the sealed ceramic 2, the hollow cavity 7 is provided with an air inlet 10 and an air outlet 11, and the digital micro-ohmmeter 4 communicates with the to-be-tested piece through a high-temperature resistant wire 5. The test piece 1 is connected and placed inside the hollow cavity 7, and sealed with a sealing flange 8. The piece 1 to be tested is made of the same material as the alloy of the heating surface to be monitored, and the material of the boiler water wall tube 12Cr1MoV is taken as an example. The two ends of the test piece 1 are respectively connected to the digital micro-ohmmete...

Embodiment 2

[0029] An on-line monitoring sensor for the corrosion depth of the heating surface of a boiler provided by the present invention includes a test piece 1, a sealed ceramic 2, a thermocouple 3, a digital micro-ohmmeter 4, a high temperature resistant wire 5, an air intake pipe 6, a hollow cavity 7, a sealed Flange 8 and temperature control module 9; wherein, the piece 1 to be tested is fixed in the sealed ceramic 2, the hollow cavity 7 is provided with an air inlet 10 and an air outlet 11, and the digital micro-ohmmeter 4 communicates with the to-be-tested piece through a high-temperature resistant wire 5. The test piece 1 is connected and placed inside the hollow cavity 7, and sealed with a sealing flange 8. The piece 1 to be tested is made of the same material as the alloy of the heating surface to be monitored, taking Super304H material of a boiler superheater and reheater pipe as an example. The two ends of the test piece 1 are respectively connected to the digital micro-ohm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com