Industrial equipment remaining useful life prediction method and system and electronic equipment

A technology of effective life and industrial equipment, applied in forecasting, electrical digital data processing, instruments, etc., can solve the problems of random aging mechanism, difficult to analyze model, difficult to establish model environmental noise and degradation mechanism, etc., to achieve good generalization ability, the effect of improving forecast speed and forecast accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the purpose, technical solutions, and advantages of this application clearer, the following further describes this application in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the application, and not used to limit the application.

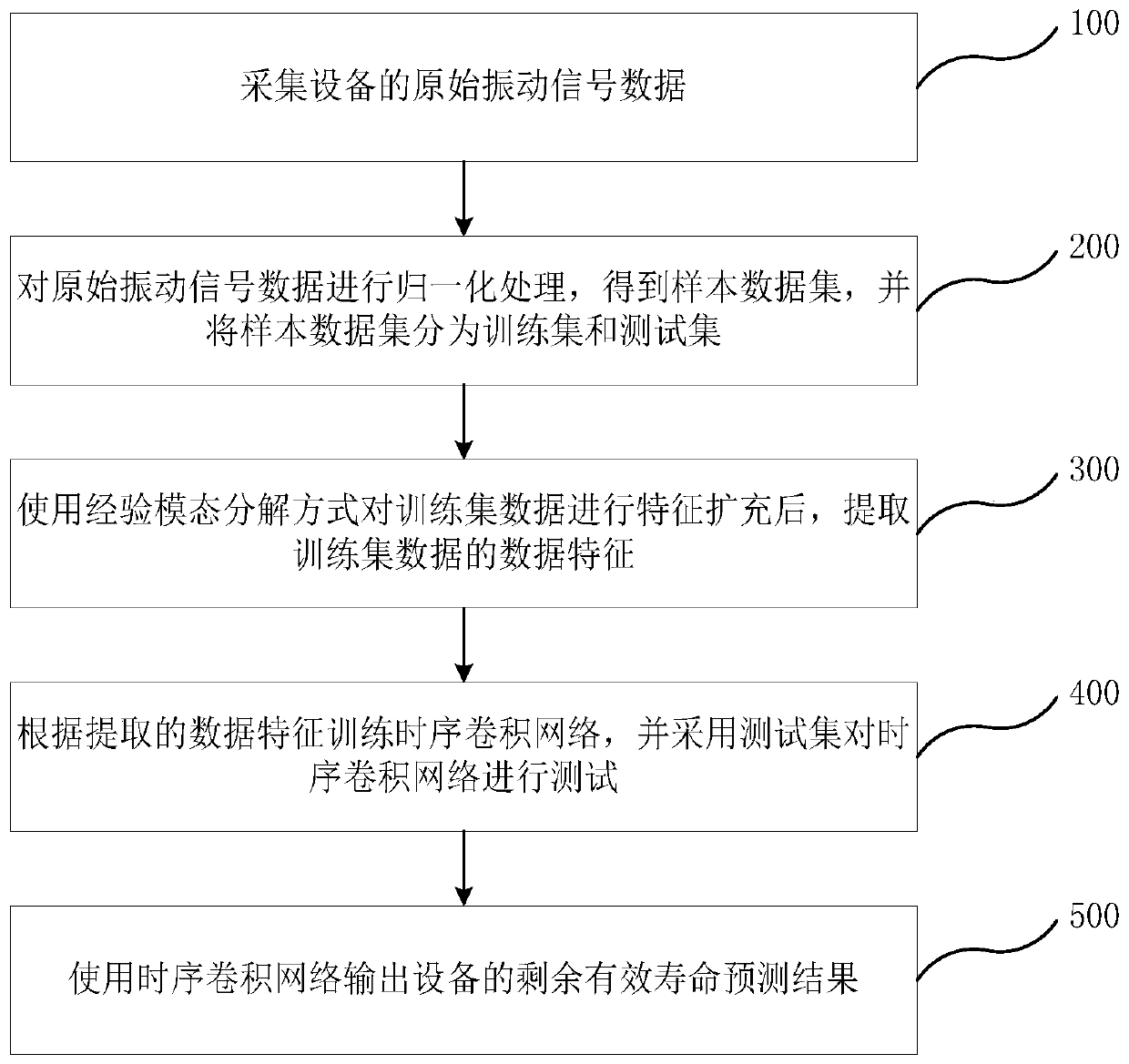

[0058] See figure 1 , Is a flowchart of the method for predicting the remaining useful life of industrial equipment in an embodiment of the present application. The method for predicting the remaining effective life of industrial equipment in the embodiment of the application includes the following steps:

[0059] Step 100: Collect raw vibration signal data of the equipment;

[0060] Step 200: normalize the original vibration signal data to obtain a sample data set, and divide the sample data set into a training set and a test set;

[0061] In step 200, because different data have different specification units, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com