Method for predicting dead stock column temperature of iron-making blast furnace core

A technology for ironmaking blast furnaces and furnace cores, applied to instruments, complex mathematical operations, calculations, etc., to achieve stable parameter estimates, simple calculations, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

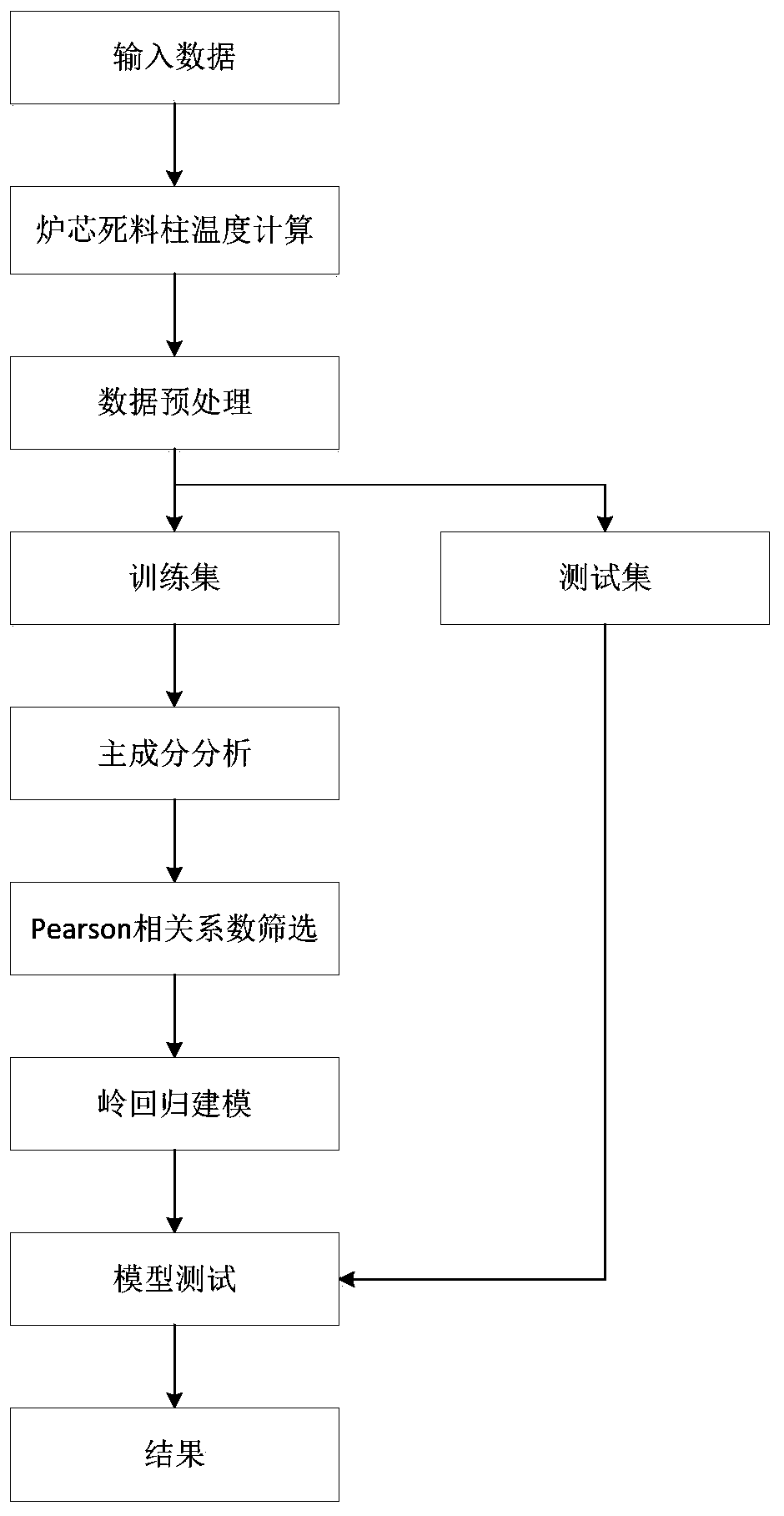

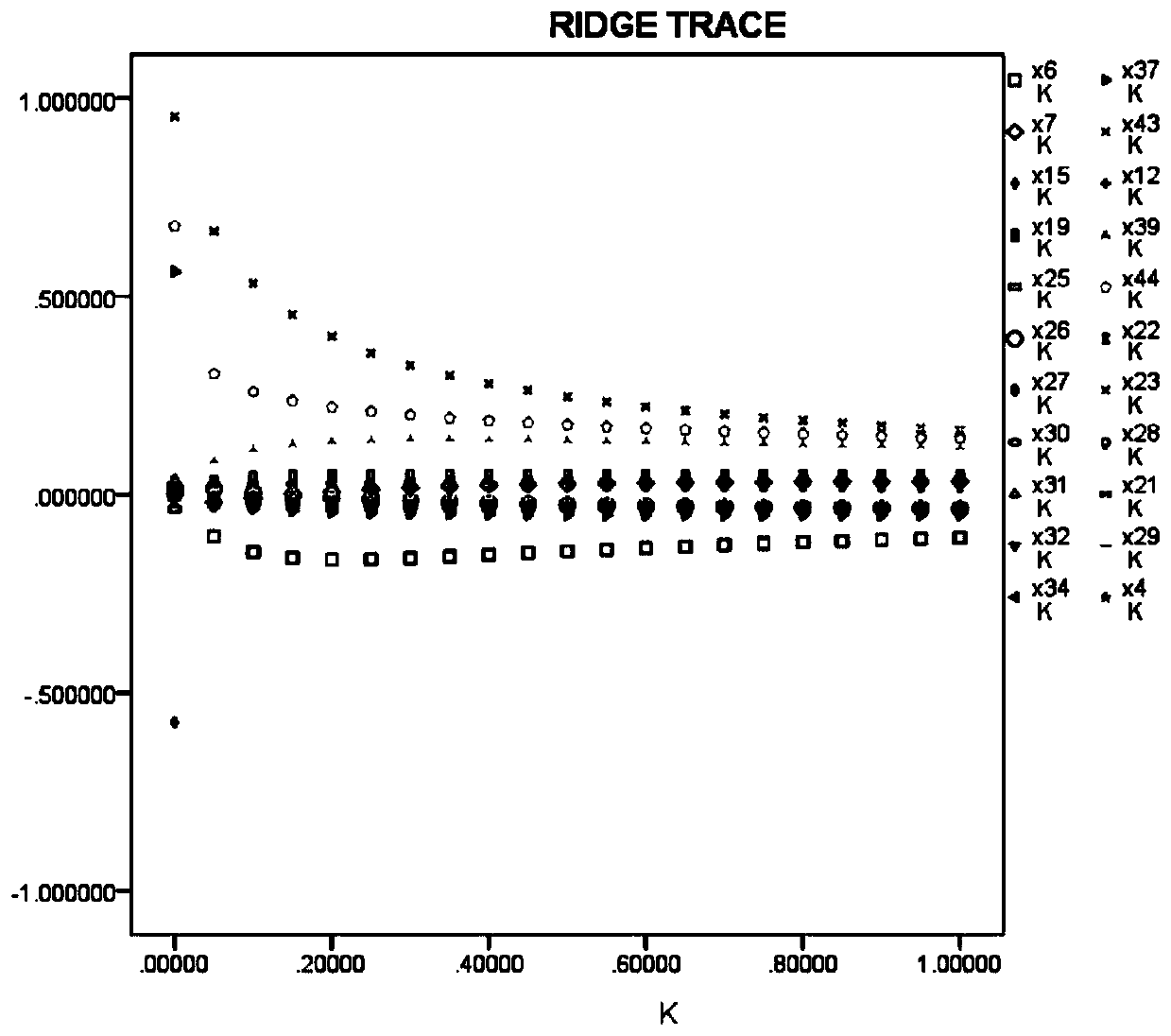

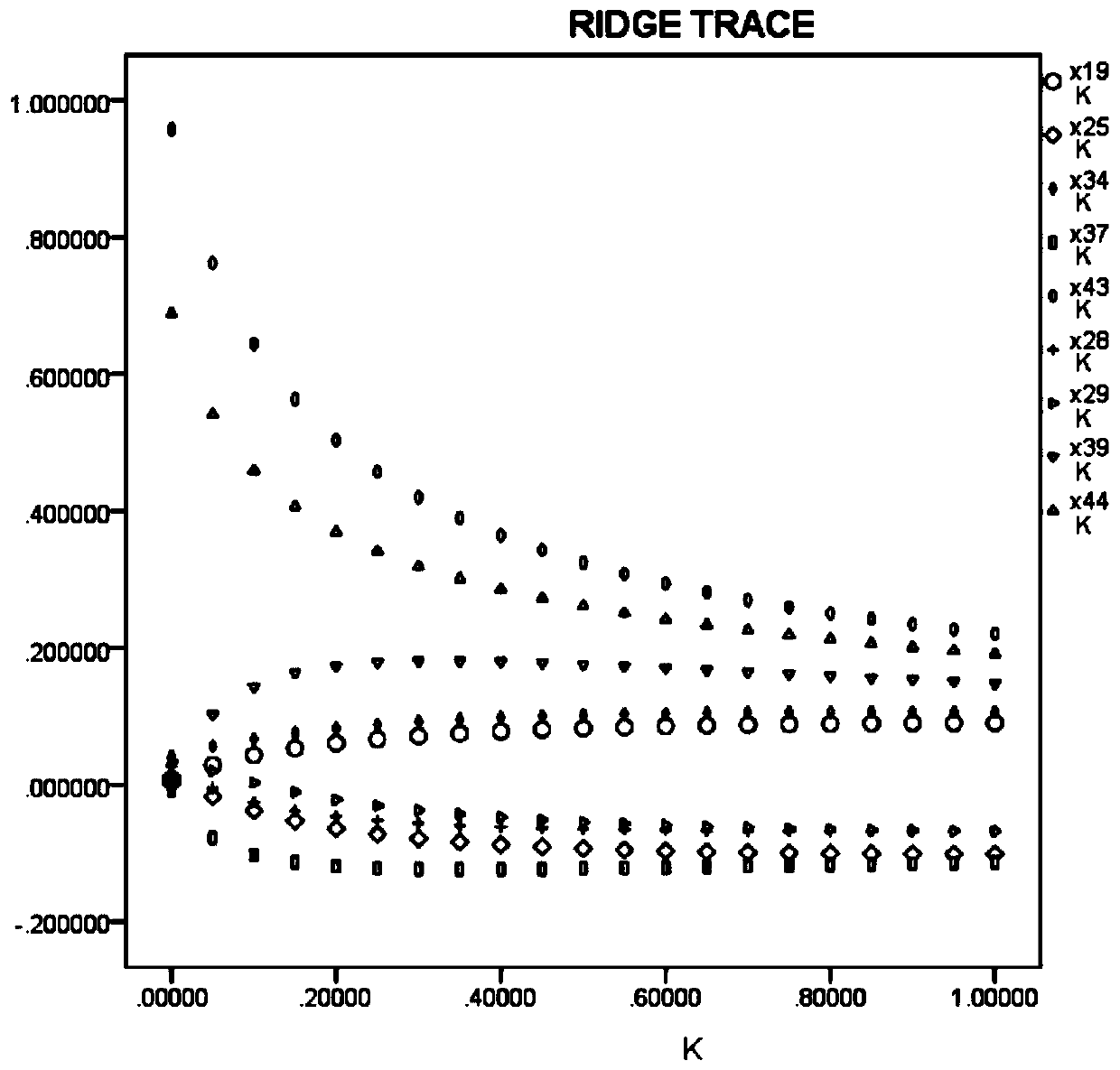

[0044] combine figure 1 As shown, a method for predicting the temperature of the dead material column of the ironmaking blast furnace core of the present invention first collects sample data and processes it, specifically, calculates the target value DMTgoal of the temperature of the furnace core dead material column by using the collected sample data; The calculated target value and sample data are processed. It is worth noting that the sample data refers to the data collected every once in a while, and finally the missing operating parameter data can be obtained. Then, the processed sample data is divided into a training set and a test set. In this embodiment, 70% of the processed sample data is used as a training set, and 30% of the processed sample data is used as a test set. Further, principal component analysis is performed on the data in the training set, and variables are selected according to the correlation between the principal components and the variables, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com